Jake’s airflow-first method for making sure a furnace in a cramped closet doesn’t choke, roar, whistle, or overheat.

🏚️ 1. The Real Problem: Tight Closets Don’t Choke the Furnace — the Return Does

Icon: 🏚️

Return air restrictions are the #1 silent killer of furnaces installed in tight utility closets.

Jake sees this constantly:

-

The furnace fits perfectly.

-

The supply plenum fits fine.

-

The gas line is clean.

-

The electrical is neat.

-

The venting is perfect.

-

The installation looks beautiful.

But then…

The furnace sounds like a vacuum cleaner, overheats, cycles off on limit, or whistles like a teapot.

Why?

Because the furnace isn’t choking on the closet.

It’s choking on the return air path.

Jake says:

“Most tight-closet furnace problems aren’t furnace problems. They’re return-air problems.”

The GR9S800803BN has a blower designed to move air freely. When its return path is squeezed, pinched, undersized, or poorly aligned, everything goes downhill fast.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

That’s why Jake created his Return-Air Layout Rule, a method that ensures the furnace breathes even in the tightest spaces.

📐 2. Jake’s Core Belief: “Air Has Geometry, Not Just Direction”

Icon: 📐

Amateurs think return air is simply about square inches.

Not Jake.

He sees return air as:

-

A shape

-

A pressure field

-

A pathway

-

A directional flow with impact points

-

A suction angle the blower responds to

Return air isn’t happy unless:

✔️ It enters the furnace evenly

Uneven return air makes the blower wheel pull harder on one side → vibration, noise, premature motor stress.

✔️ It avoids sharp turns

Flex ducts and elbows can create turbulence and static pressure spikes.

✔️ It isn’t starved by grille placement

A grille 2 inches from a wall can cut airflow by 40%.

✔️ The filter rack isn’t strangling it

Jake sees filter racks kill good installs more than anything else.

Jake’s rule:

“Return air must hit the blower like wind hits a sail — full face, even pressure, no swirl.”

This is how Jake solves airflow in closets that seem too small to work.

🛠️ Jake’s Return-Air Layout Rule (The 6-Step Method)

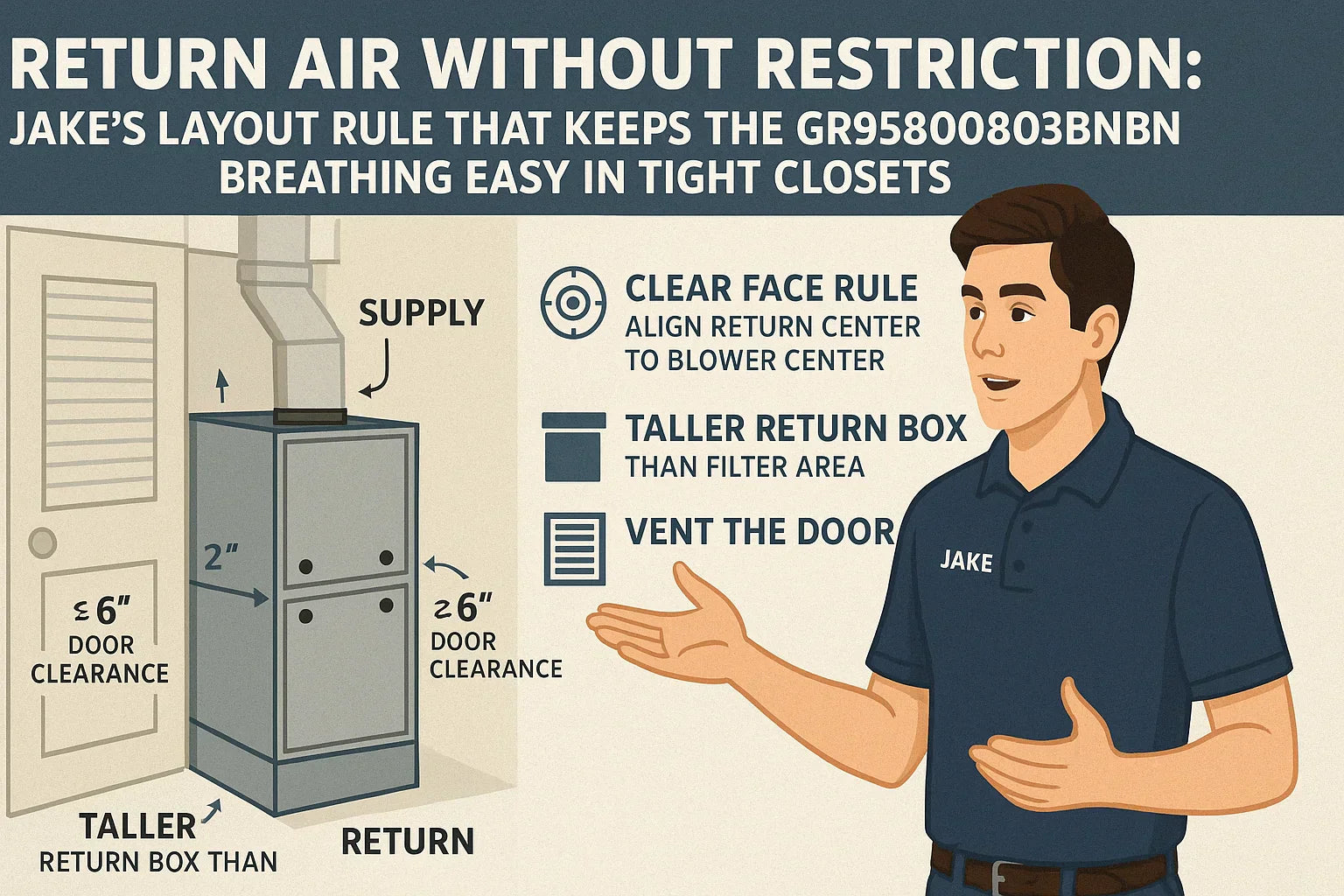

This is Jake’s process every time he installs the GR9S800803BN in a tight closet.

🧭 3. Step 1 — The “Clear Face Rule”: Align Return Center to Blower Center

Icon: 🧭

Jake always aligns the center of the return boot to the center of the blower inlet.

This is non-negotiable.

Why?

Because return air hitting the blower off-center creates:

-

Suction imbalance

-

Blower wheel turbulence

-

Increased static pressure

-

Heat exchanger hot spots

-

Loud whooshing and vibration

Jake uses a mini laser level or a simple tape measure:

-

Center of furnace rail

-

Center of blower inlet

-

Center of return drop

-

All must form a straight vertical line

If the closet is too narrow for perfect alignment, Jake shifts the return behind the furnace, not beside it.

🧱 4. Step 2 — The “Big Opening, Tight Filter” Mistake Jake Eliminates

Icon: 🧱

Many installers put a giant return box under the furnace…

…but then install a 1-inch filter rack that cuts capacity in half.

Jake has seen:

-

1-inch filters at 600–700 CFM block airflow

-

Return boxes 30"x20" still suffocate if the filter is a bottleneck

-

Dirty filters trip limits in under 5 minutes

Jake’s fix:

✔️ He uses 4-inch media filters whenever space allows

They have:

-

Lower resistance

-

Larger surface area

-

Longer lifespan

-

Less noise

✔️ If space won’t allow 4-inch

Jake installs two 1-inch filters in parallel, doubling the air surface.

He says:

“If the filter isn’t breathing, the furnace isn’t breathing.”

🪟 5. Step 3 — The Closet Door Isn’t a Wall — Vent It

Icon: 🪟

Tight closets need door venting unless the return is fully ducted.

Too many installs rely on:

-

Cracks under the door

-

Hollow-core doors

-

Accidental gaps

Jake’s rule:

✔️ 1 square inch of free area per 1,000 BTUs

With 80,000 BTUs:

80 square inches minimum.

Jake prefers:

-

Two high vents

-

Two low vents

OR

-

A fully louvered door (best)

Jake says:

“You don’t want the furnace pulling air from the attic or crawlspace. Give it a door that breathes.”

🌀 6. Step 4 — Keep the Return Box Taller Than the Filter Area

Icon: 🌀

Jake’s geometry rule:

Return box height ≥ Filter height

If the return box is shorter than the filter rack:

-

Air slams into the rack

-

Pressure spikes

-

Whistle noise appears

-

Furnace breathes unevenly

-

Heat exchanger hotspots develop

Jake builds return boxes:

-

4–6 inches taller than the filter

-

With smooth interiors (no screws sticking inside)

-

With a tapered transition for even airflow

This alone can drop static pressure by 0.1–0.2 inches WC, which is huge in a tight closet.

🎯 7. Step 5 — The “Sound Test”: How Jake Finds Hidden Restrictions

Icon: 🎯

Jake listens for these three sounds:

1️⃣ Whistle

Cause: filter restriction or tight grille spacing.

2️⃣ Drum hum

Cause: return duct cavitation or thin metal buckling under negative pressure.

3️⃣ Slurp / suction snap

Cause: closet door starving the furnace of air.

Jake tests with:

-

The door open

-

The door closed

-

The filter removed

-

The grille taped temporarily

Each test isolates a restriction.

Jake says:

“Your ears will diagnose airflow before any manometer will.”

📏 8. Step 6 — Jake’s Minimum Clearances for Tight Closet Returns

Icon: 📏

Jake follows simple geometry rules for closet installs:

✔️ Side clearance

2 inches minimum between furnace and wall (return side).

✔️ Door clearance

At least 6 inches from the furnace face to door inner surface.

✔️ Return opening

Minimum 16" x 25" for a GR9S800803BN at full airflow.

✔️ Grille spacing

Grille must be 3 inches away from any obstruction.

✔️ Return duct

Minimum 14" round or 12"x24" rectangular.

✔️ Pressure

Return static pressure should be ≤ 0.3 inches WC.

Older homes? Jake still hits these numbers by modifying layout.

💨 Why This All Matters for Furnace Health

⚠️ 9. The Consequences of Poor Return Air in Tight Closets

Icon: ⚠️

Jake lists the top silent killers:

✔️ Overheating

Trips limit. Happens constantly.

✔️ Flame disturbance

Poor return → blower strain → flame ripple → rollout risk.

✔️ Noise

The blower becomes loud enough to hear from upstairs.

✔️ Motor stress

ECM and PSC blowers burn out faster when starved.

✔️ Heat exchanger cracks

Uneven airflow = uneven heat.

Jake has seen:

-

Cracks in < 5 years

-

Burn marks on the door

-

Furnace doors rattling

-

Filters bent inward from suction

-

Return ducts imploding

Return air is not optional.

It’s structural to furnace safety.

📚 10. External Verified Resources (Up to 6)

(All safe, non-competing, government or engineering resources)

-

ENERGY.gov — Furnace airflow & installation guidance

https://www.energy.gov/energysaver/furnaces-and-boilers -

U.S. Consumer Product Safety Commission — Heating system airflow & ventilation safety

-

ASHRAE Standards — Airflow, ventilation, and duct sizing

https://www.ashrae.org -

Heating, Ventilation and Air-Conditioning Systems, Part of Indoor Air Quality Design Tools

🏁 11. Jake’s Final Word

Jake says it like he means it:

“Returns don’t just feed the furnace. They calm it.”

“If the return breathes easy, the whole system breathes easy.”

When you follow Jake’s Return-Air Layout Rule:

-

The GR9S800803BN runs cooler

-

The blower runs quieter

-

The heat exchanger lasts longer

-

The closet stays calm

-

The homeowner never hears a complaint

Better airflow = better comfort.

Every. Single. Time.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The 8-Degree Rule: Jake’s Bulletproof Method for Zero-Condensation on Horizontal Installs