When I bought my Weil-McLain CGI-4 Series 4, 90,000 BTU cast iron natural gas boiler, I wasn’t just thinking about heat. I was worried about whether it would actually fit my utility room. Would I still be able to use the space for storage? Would it make too much noise near my home office? Would my old chimney venting even work?

If you’re asking the same questions, you’re not alone. I’ll walk you through exactly what I learned about space requirements, noise, and venting so you know whether a boiler this size is a good fit for your home.

📦 How Big Is a 90,000 BTU Boiler?

First things first — dimensions matter.

-

The Weil-McLain CGI-4 Series 4 is designed to be compact for a cast iron boiler.

-

Approximate size: 30" tall, 19" wide, and 27" deep (varies slightly by model year).

-

Weight: Around 300 lbs — it’s a heavy-duty piece of equipment.

🔗 Reference: Weil-McLain Gas Boiler Specs

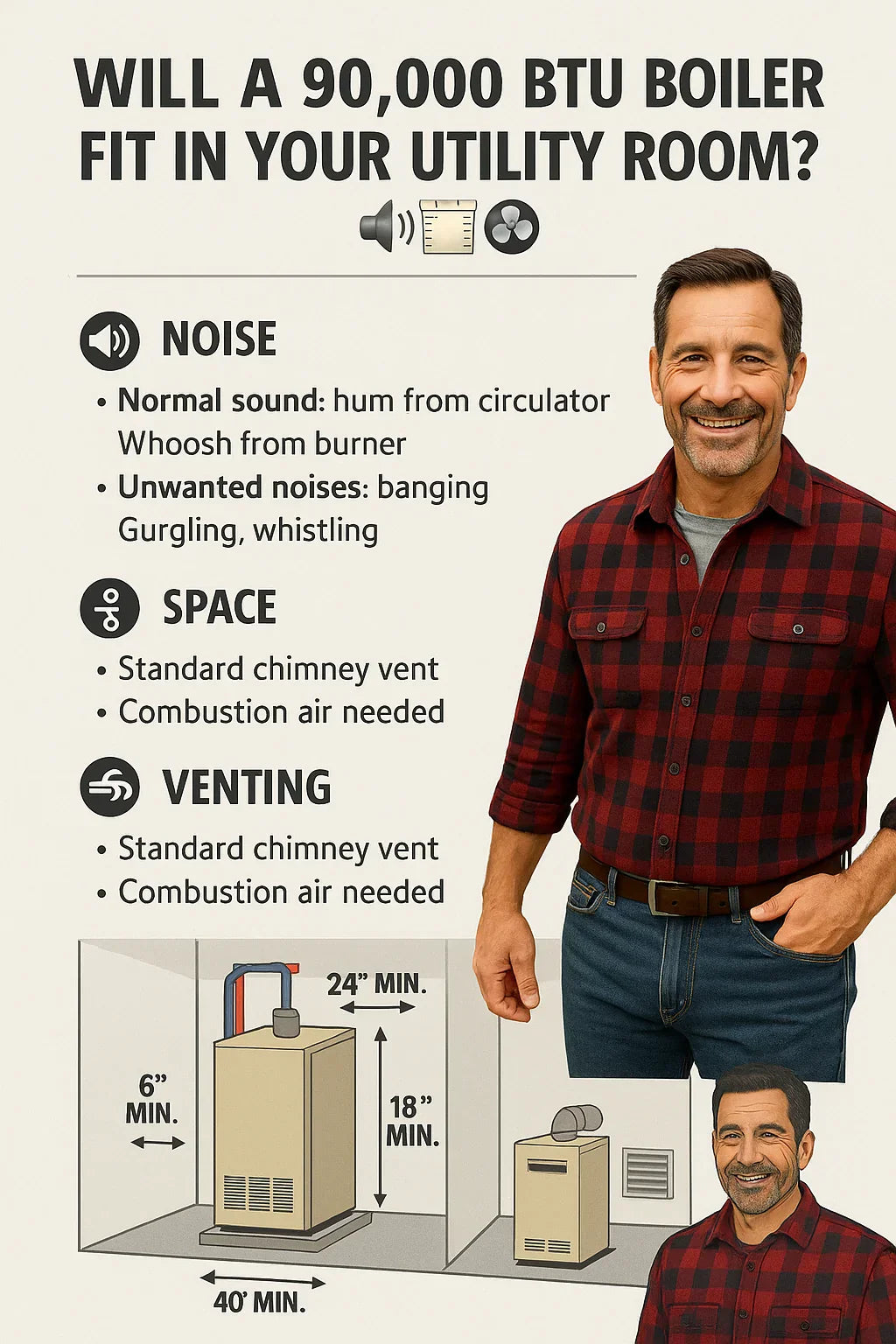

Clearance Requirements

According to Weil-McLain’s installation manual, here’s what you’ll need:

-

6" minimum from sides.

-

24" minimum at the front for service access.

-

18" recommended overhead clearance.

-

Clear floor space for piping and expansion tank.

💡 Mike’s Note: Don’t try to squeeze your boiler into a closet unless it’s built for mechanical equipment. You’ll thank yourself later when it’s time to replace a circulator pump or pressure relief valve.

🏠 Will It Fit in a Typical Utility Room?

For most homes, yes. Here’s what I considered before setting mine in place:

-

Basement utility rooms: Plenty of space, usually ideal.

-

First-floor closets or laundry rooms: Possible, but may require fire-rated enclosures and extra venting.

-

Small utility spaces: Still workable if you maintain clearance and access for service.

👉 If your room is less than 5’ x 7’, you’ll need to be strategic about layout.

🔗 Energy.gov Heating Systems Guide has examples of how boilers are typically placed.

🔊 Noise Considerations: How Loud Is a 90k BTU Boiler?

I was nervous about this — my utility room is right next to my basement office.

Normal Operating Noise

-

Circulator pump hum: Steady, low-pitched vibration.

-

Gas burner whoosh: Sounds like a small jet starting up, but only when firing.

-

Water flow gurgle: Should be smooth and quiet if bled properly.

Problematic Noises (What They Mean)

-

Banging (“kettling”): Caused by scale buildup in the heat exchanger.

-

Gurgling: Air trapped in the system.

-

Whistling: Pressure issues or venting restrictions.

💡 Mike’s Note: With the door closed, I barely hear my CGI-4. Cast iron boilers are much quieter than forced-air furnaces or on-demand water heaters.

🌬️ Venting Requirements for a 90k BTU Boiler

Venting is where I hit the most surprises.

Chimney Venting

-

The Weil-McLain CGI-4 uses a Category I vent (natural draft, through a chimney).

-

Requires a lined chimney — stainless steel liners are recommended for older chimneys.

-

Vent pipe must slope upward ¼” per foot toward the chimney.

Combustion Air

Your boiler needs oxygen to burn fuel safely.

-

Open utility rooms: Usually fine if the room is large enough.

-

Tight spaces: May require louvered doors or direct outside air intakes.

-

Code requirement: Typically 50 cubic feet of room volume per 1,000 BTUs input. For a 90k BTU boiler, that’s 4,500 cubic feet of room space — or supplemental air intake.

🔗 DOE – Venting Gas Appliances

💡 Mike’s Note: I added a small louvered vent in my utility room door. It cost $20 and ensures proper combustion air.

🛑 Common Mistakes Homeowners Make

After talking with contractors and seeing a few bad installs, here are the mistakes I see most:

-

No clearance: Boiler crammed in too close to a wall → techs can’t service it.

-

Improper vent slope: Flue gases backdraft into the home.

-

No combustion air: Boiler starves for oxygen, runs inefficiently, or shuts down.

-

Ignoring soundproofing: Thin walls near living space amplify normal noise.

📋 Code & Safety Considerations

Most of what determines fit comes down to building codes and manufacturer instructions:

-

Clearances: Always follow the boiler manual.

-

Venting: Must comply with NFPA 54 (National Fuel Gas Code).

-

Combustion air: Required by code if space is too small.

-

Floor protection: Concrete pad or corrosion-resistant base recommended.

💲 Cost Implications of Space & Venting

Here’s what I paid extra because of space/venting issues:

-

Chimney liner (stainless steel): $400

-

Louvered vent for combustion air: $20

-

Extra piping for clearance routing: $150

Total extras: about $600.

👉 Budget for venting and clearance adjustments — they’re almost always needed.

📝 Mike’s Final Word

Yes — a 90,000 BTU boiler like the Weil-McLain CGI-4 will fit in most utility rooms. But you’ll want to plan for three things:

-

Space: Leave at least 24" at the front for service.

-

Noise: Expect a quiet hum, but nothing that will disturb most rooms.

-

Venting: Make sure your chimney is lined and the room has enough combustion air.

👉 My advice: Before you buy, measure your room, check your venting, and think about airflow. A little prep ensures your boiler doesn’t just heat your home — it fits your home.

In the next topic we will know more about: Heating Performance in Winter: Can the CGI-4 Handle Extreme Cold?