When I first considered upgrading to the Weil-McLain CGA-6 Series 3 166,000 BTU cast iron gas boiler, I wasn’t worried about BTUs or AFUE. I was worried about something much more practical: Would it even fit in my house?

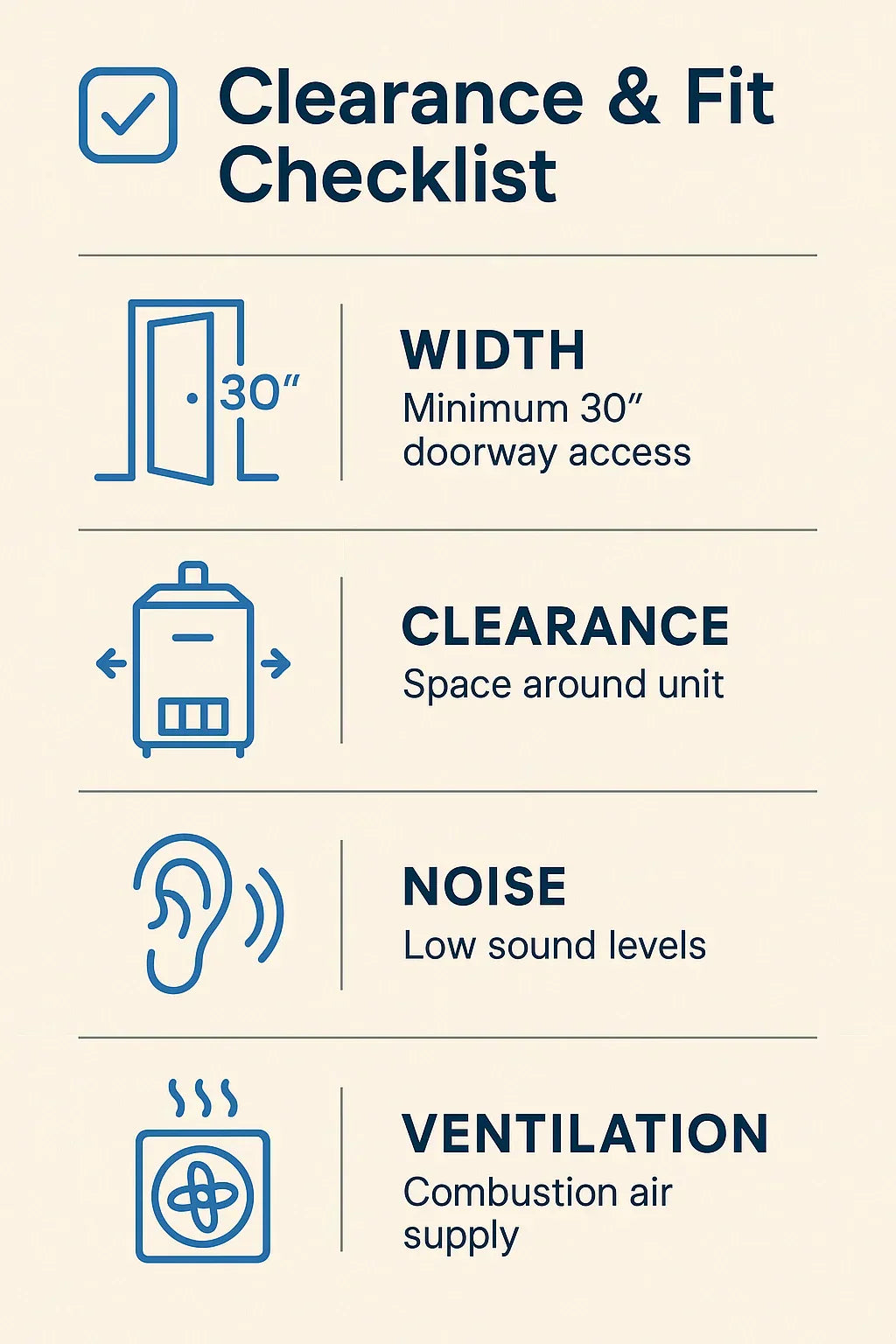

A boiler this size is a big piece of equipment, and planning for installation isn’t just about heating capacity. You need to think about noise levels, space requirements, service clearances, and even how it changes the design of your mechanical room.

This guide walks you through everything I learned (sometimes the hard way) about fitting a large boiler into a residential home.

📦 Dimensions & Weight of the Weil-McLain CGA-6

The CGA-6 is built from heavy-duty cast iron. That means:

-

Weight: ~500 lbs dry (before water is added).

-

Dimensions: Roughly 30” wide, 40” tall, and 25” deep (varies slightly with trim kits).

👉 Translation: It’s heavy, bulky, and awkward to maneuver into basements or utility spaces.

Delivery & access considerations

-

Narrow doorways: My contractor had to remove the basement door from its hinges to get the unit through.

-

Staircases: Steep basement stairs are a challenge—plan on multiple movers or a dolly system.

-

Floor strength: Cast iron boilers should always sit on a concrete pad or basement slab, never on wood flooring.

🔗 Weil-McLain Residential Boiler Specs

📏 Clearance Requirements

Boilers need room to breathe—not just for safety, but for service.

Weil-McLain CGA-6 recommended clearances:

-

Front: 24” minimum (for service and cleaning).

-

Sides: 6” minimum from combustible surfaces.

-

Top: 24” minimum for piping and vent connections.

-

Back: 6” minimum.

Venting space

-

The CGA-6 uses chimney venting. Ensure you have chimney access and room for a liner if required.

-

Stainless steel liners may add ½” to 1” of clearance.

💡 Samantha’s tip: Leave more than the minimum. I left 30” in front, and I’m glad I did—my tech had room to work without contorting like a gymnast.

🔗 NFPA 54 – National Fuel Gas Code

🔊 Noise Levels

I was worried that a 166,000 BTU boiler would sound like a jet engine. The good news? Cast iron boilers are surprisingly quiet.

Why cast iron is quieter:

-

Heavy sections absorb vibration.

-

Simple atmospheric burners don’t have the whine of high-speed fans.

-

Pumps and circulators make a low hum, not a roar.

👉 My old steel boiler rattled and clanged constantly. The CGA-6? You barely notice it running.

Placement strategies to minimize noise

-

Basement corner is best—away from bedrooms.

-

Add rubber vibration pads under circulator pumps.

-

Insulate nearby piping to reduce expansion noises.

🔗 DOE – Boiler Noise Troubleshooting

🏠 Mechanical Room Design

A boiler isn’t just a piece of equipment—it reshapes your mechanical room.

Ventilation requirements

-

Fresh air supply is required for combustion.

-

Small sealed utility rooms may need louvered doors or ducted makeup air.

Access for service

-

Don’t block the boiler in with shelving or storage.

-

Leave enough room for a tech to replace pumps, valves, or controls.

Combining with water heating

-

The CGA-6 can be paired with an indirect water heater.

-

Plan wall space for an expansion tank, pumps, and control panel.

💡 Samantha’s mistake: I had to move storage shelves after install because I hadn’t planned for the expansion tank clearance.

🔗 ASHRAE Residential HVAC Guidelines

🎨 Aesthetics & Home Integration

Let’s be honest—boilers aren’t pretty. But you can design your utility area to stay functional and even attractive.

Options I considered:

-

Enclosure with louvered doors: Maintains airflow while hiding the unit.

-

Painted mechanical room: A fresh coat of white paint on basement walls made the area feel less industrial.

-

Utility zoning: I relocated laundry machines to the opposite wall, keeping heat equipment separate.

👉 It’s not HGTV, but with a little thought, your mechanical room doesn’t have to be an eyesore.

📝 Samantha’s Real-World Notes

-

Delivery surprise: My CGA-6 barely fit through the stairwell landing—it took three installers and a lot of patience.

-

Noise relief: Once installed, it was far quieter than I expected. My old boiler woke me up at night—the CGA-6 doesn’t.

-

Clearance lesson: I left extra space in front, and it made annual maintenance much easier.

-

Room redesign: I ended up reorganizing my basement around the boiler—but now it feels like a dedicated, well-planned utility space.

💵 Cost Impact of Space & Design

Sometimes “fit” isn’t just physical—it’s financial.

-

Extra movers/delivery challenges: $200–$400 if multiple techs are needed.

-

Chimney liner upgrades: $800–$1,500.

-

Mechanical room modifications: $500–$2,000 depending on complexity.

-

Noise mitigation (pads, insulation): $100–$300.

👉 My total install was about $12,000, and around $1,000 of that was purely space/clearance related work.

✅ Key Takeaways

-

The Weil-McLain CGA-6 is a large, heavy unit—plan delivery and access carefully.

-

Leave ample clearance for service and ventilation—more than the bare minimum.

-

Noise is low compared to other systems, but placement still matters.

-

Expect your mechanical room design to change—plan shelves, laundry, and storage around the boiler.

-

Budget for extra space-related costs like chimney liners, delivery, and room modifications.

💡 Samantha’s advice: Don’t just size your boiler in BTUs—make sure it “sizes” into your home’s physical space and design too.

In the next topic we will know more about: Is a 166,000 BTU Boiler Right for Your Home? Sizing Tips & Floorplan Guidance