When I first installed my Weil-McLain CGI-4 Series 4 90,000 BTU Cast Iron Boiler, I thought I was done. New boiler, check. Warm house, check. But a year later, after hearing a few strange noises and seeing my gas bill climb, I realized something important:

👉 A boiler is only as good as the maintenance you put into it.

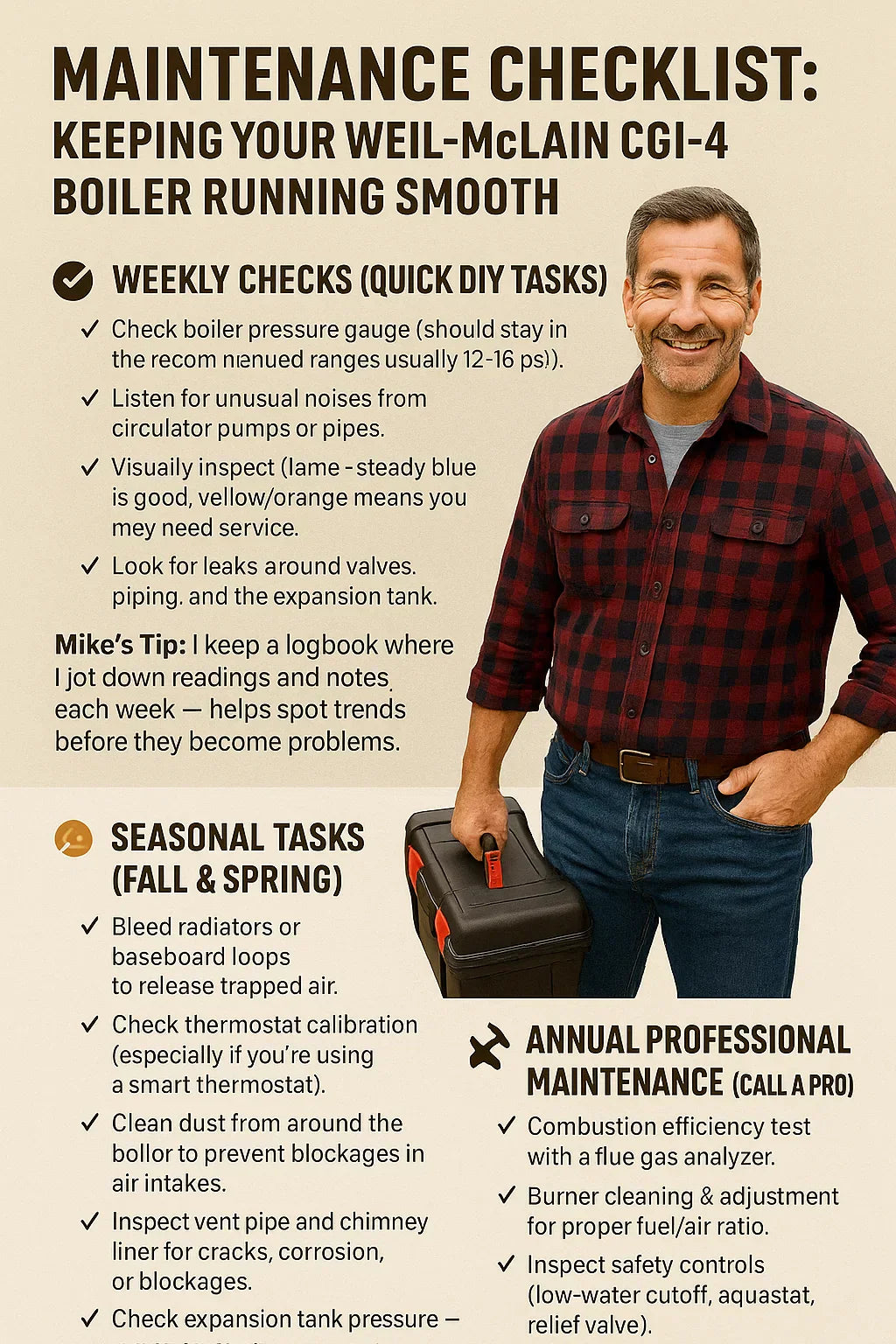

In this guide, I’ll walk you through exactly how I keep my CGI-4 boiler running smooth — broken down into weekly, seasonal, and annual tasks. I’ll also share the lessons I learned the hard way so you don’t have to.

📐 Why Boiler Maintenance Matters

Here’s the deal: Boilers are built tough, especially cast iron models like the CGI-4. But even cast iron doesn’t protect you from:

-

Efficiency loss — Dirt, soot, and sediment reduce heat transfer.

-

Shortened lifespan — Lack of flushing and corrosion prevention can kill a boiler early.

-

Higher bills — A poorly tuned burner wastes fuel.

-

Safety risks — Gas leaks and carbon monoxide issues can happen without warning.

According to the U.S. Department of Energy, a well-maintained boiler can last 20–30 years. Skip the basics, and you might be replacing yours in 10.

✅ Weekly Maintenance Tasks (Quick DIY)

I set aside 10 minutes every Sunday morning with my coffee to check these items:

1. 🔍 Check Boiler Pressure & Temperature

-

The gauge should read 12–15 psi when cold.

-

Operating temperature should be around 180°F during heating cycles.

-

Large swings can mean expansion tank or relief valve issues.

2. 👂 Listen for Strange Noises

-

Gurgling = air trapped in pipes.

-

Banging = “kettling” from scale buildup.

-

Grinding = circulator pump trouble.

3. 🔥 Observe the Burner Flame

-

Flame should be steady blue.

-

Yellow or orange = incomplete combustion, soot, or dirty burner.

4. 💧 Look for Leaks

-

Around the circulator pump seals.

-

Under valves and connections.

-

On the floor around the boiler base.

💡 Mike’s Tip: Keep a logbook of weekly readings (pressure, temp, and notes). When something looks off, you’ll know it right away.

🍂 Seasonal Maintenance (Fall & Spring)

Before firing up the boiler in fall and after shutting it down in spring, I run through this list:

1. 🩸 Bleed Radiators or Baseboard Loops

-

Start at the top floor and work down.

-

Use a radiator key or flat screwdriver.

-

Catch water in a cup to prevent stains.

🔗 Here’s a good step-by-step from Family Handyman

2. 🖥️ Test the Thermostat

-

Make sure it triggers the boiler properly.

-

If using a smart thermostat, update firmware and check Wi-Fi connection.

3. 🧹 Clean Dust & Debris Around the Boiler

-

Keep a 2-foot clearance zone around the unit.

-

Vacuum dust buildup near intakes and floor.

4. 🪟 Inspect Venting System

-

Check chimney liner or vent pipe for cracks or corrosion.

-

Ensure vent joints are sealed tightly.

5. ⚖️ Check Expansion Tank

-

Tap the tank lightly: one half should sound hollow (air) and the other solid (water).

-

If it feels full of water, it may be waterlogged and need replacing.

🔧 Annual Maintenance (Call in a Pro)

Even though I’m a DIY guy, there are a few things I let the professionals handle once a year.

1. 📊 Combustion Efficiency Test

-

Pro uses a flue gas analyzer to measure oxygen, CO2, and CO.

-

Adjusts burner for proper air/fuel mix.

2. 🔥 Burner & Heat Exchanger Cleaning

-

Removes soot, rust, and debris that cut efficiency.

-

Brushes and vacuums inside the combustion chamber.

3. ⚡ Test Safety Devices

-

Pressure relief valve should release at 30 psi.

-

Low-water cutoff must shut the system down properly.

-

Aquastat calibrated for correct temps.

4. 💧 Flush Sediment from Boiler

-

Connect hose to drain valve.

-

Flush until water runs clear.

-

Helps prevent scaling and “kettling.”

🔗 HVAC.com annual boiler service checklist

5. 🔎 Gas Line & Valve Inspection

-

Check joints with soap solution for leaks.

-

Ensure shutoff valve operates smoothly.

🛑 Safety Must-Dos (Don’t Skip These)

If there’s one section to tattoo in your brain, it’s this one:

-

Install carbon monoxide detectors near sleeping areas and in the boiler room.

-

Test CO detectors monthly and replace batteries yearly.

-

Keep boiler room well-ventilated — no clutter or stored chemicals.

-

Never plug or cap the pressure relief valve.

-

If you smell gas, shut everything down and call your utility immediately.

📝 Tools & Supplies I Keep on Hand

Here’s my small “boiler kit” that lives in the utility room:

-

Radiator key / screwdriver

-

Pressure gauge tester

-

Small wet/dry shop vac

-

Flashlight & inspection mirror

-

Rags & leak-detection soap solution

-

Replacement gaskets, valves, and Teflon tape

🔗 This Old House guide on boiler tools

💲 How Maintenance Saves You Money

I learned this lesson the hard way: A neighbor ignored maintenance for years. His CGI boiler scaled up so badly it cracked the heat exchanger — $3,000 gone in a flash.

Here’s how maintenance pays off:

-

10–15% fuel savings from clean burners (Energy Star).

-

Longer lifespan — Cast iron can last 25–30 years if maintained.

-

Fewer breakdowns — Emergency calls average $150–$500 per visit.

-

Higher resale value — A documented maintenance history impresses buyers.

📅 Mike’s Maintenance Calendar (At a Glance)

-

Weekly: Pressure, flame, leaks, logbook.

-

Fall: Bleed radiators, test thermostat, inspect vents.

-

Spring: Flush boiler, check expansion tank.

-

Annually (Pro): Combustion test, burner cleaning, safety checks.

📝 Mike’s Final Word

Here’s the truth: Maintaining your Weil-McLain CGI-4 boiler isn’t hard. Most of it is quick DIY work that takes less time than mowing the lawn. And the payoff? Lower bills, reliable heat, and peace of mind.

I’ve learned that treating your boiler like a partner — instead of a black box in the basement — means it’ll take care of you for decades.

👉 If you want comfort all winter without surprise repair bills, make this maintenance checklist your routine.

In the next topic we will know more about: Troubleshooting Guide: What to Do If Your Gas Boiler Isn’t Heating Right