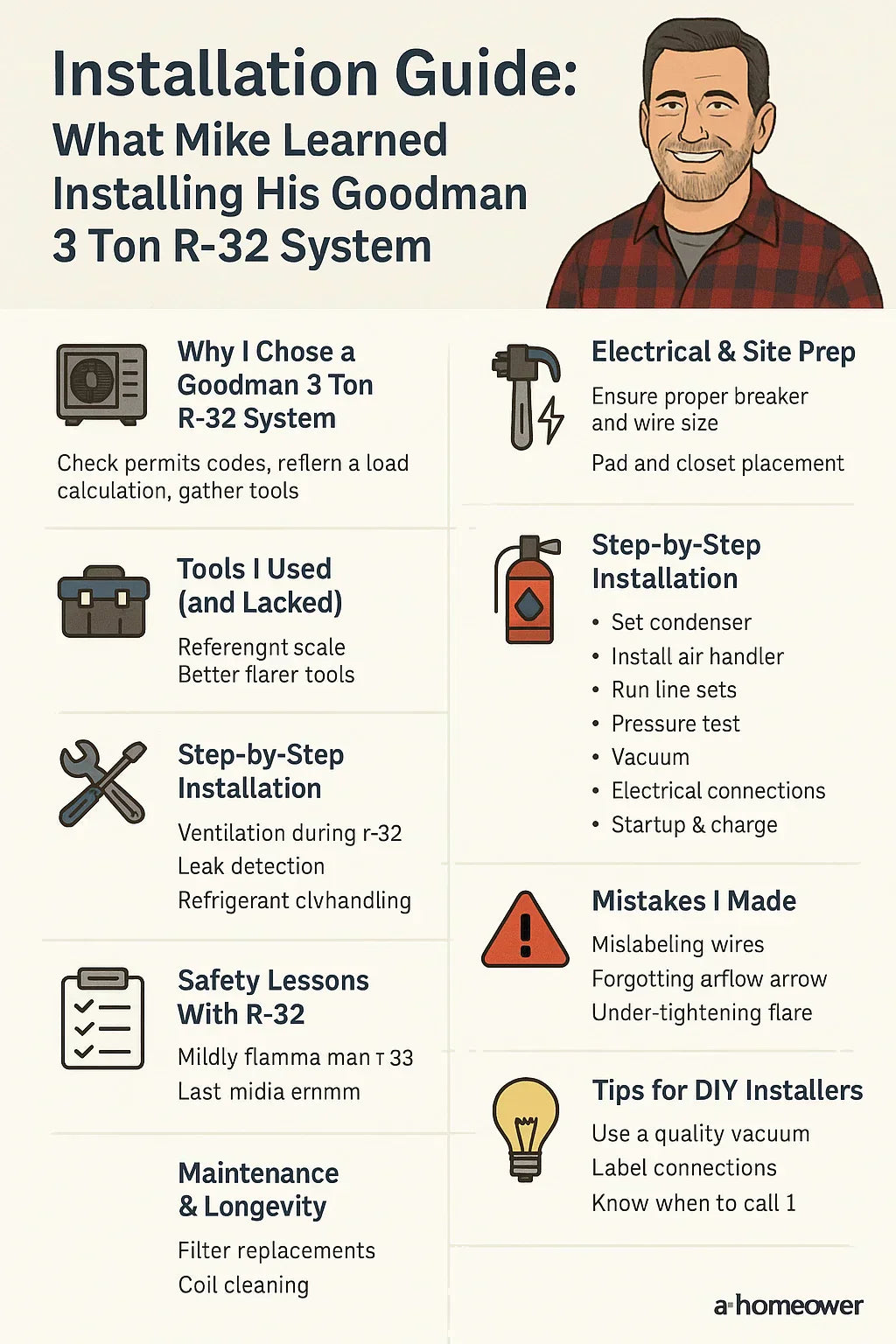

Hello there — Mike Sanders here. I’ve been a homeowner long enough to know that installing a new air conditioning system can feel intimidating. When I decided to replace my old R-410A unit with a Goodman 3 Ton 14.5 SEER2 R-32 system (model GLXS4BA3610 condenser paired with the AMST36CU1300 air handler), I knew I’d be in for a learning experience.

This guide is my way of sharing that journey — the lessons I learned, the mistakes I made, and the tips I’d give any other homeowner thinking about installing their own Goodman 3 ton R-32 system.

I’ll break it all down step by step, from planning to tools, wiring, refrigerant safety, and the final startup. My goal is simple: help you feel more prepared and confident when it comes to your own project.

🏡 1. Why I Chose the Goodman 3 Ton R-32 System

When our summers started pushing past 95°F and the electric bills climbed higher, my old system couldn’t keep up. After some research, I landed on the Goodman 3 Ton R-32 system. Here’s why:

-

Size fit: My 1,800 square foot home falls right in the sweet spot for a 3 ton unit.

-

Efficiency: At 14.5 SEER2, it hits today’s energy efficiency standards without breaking the bank.

-

R-32 refrigerant: Goodman has transitioned to R-32, which offers better heat transfer and a much lower environmental impact compared to R-410A. (EPA – Transitioning to R-32)

-

Reputation: Goodman is known for affordability and solid reliability, which felt like the right balance for me.

📋 2. Pre-Installation Planning: What You Need to Know First

One thing I’ll stress up front: you can’t wing an installation like this. Planning is half the battle.

2.1 Permits and Codes

Check your local building codes before starting. Some jurisdictions require permits for AC installs, especially since R-32 is classified as A2L (mildly flammable) by ASHRAE (ASHRAE Safety Standards).

2.2 Load Calculation (Manual J)

Don’t just go by square footage — get a proper Manual J load calculation to confirm that 3 tons is the right fit. (ACCA – Manual J)

2.3 Tool & Supplies Checklist

Here’s what I had ready:

-

Refrigeration gauges and hoses

-

Torque wrench for flare fittings

-

Nitrogen tank and regulator (for pressure testing)

-

Micron gauge and vacuum pump

-

Drill, anchors, level, screwdrivers

-

Electrical tester & wire strippers

-

PPE (gloves, safety glasses, respirator for refrigerant handling)

And yes, a helper — some equipment is heavy and awkward to move alone.

🧰 3. Tools Mike Actually Used (and a Few I Wished I Had)

I thought I had everything, but installation reminded me: the right tool at the right time saves hours of frustration.

Must-Haves:

-

Micron gauge: My old analog gauge couldn’t tell me if the system was under 500 microns; the new digital one did.

-

Torque wrench: Flare fittings are sensitive — overtightening can crack them, undertightening can leak.

-

Vacuum pump: A deep vacuum is non-negotiable.

Wish-I-Had:

-

Flare block with clutch: Mine was basic and made it too easy to mis-flare lines.

-

Refrigerant scale: I borrowed one from a friend to measure charge precisely.

Lesson: don’t skimp on specialized HVAC tools. They’re worth the cost.

⚡ 4. Electrical & Site Prep: Setting the Stage

Before bringing in the new system, I had to prep both outside and inside.

4.1 Electrical Panel & Breakers

The Goodman condenser requires its own dedicated breaker. I verified:

-

Breaker size matched Goodman’s specs.

-

Wire gauge was correct (too small = heat/fire risk).

-

Disconnect box was installed near the condenser.

4.2 Outdoor Condenser Placement

I poured a level pad, added vibration pads, and ensured 2–3 feet of clearance around the unit for airflow and service access.

4.3 Indoor Air Handler Placement

The AMST36CU1300 went in my utility closet. Key lessons:

-

Leave at least 24" clearance in front for servicing.

-

Make sure airflow direction matches duct layout (yep — I almost messed this up).

-

Secure the cabinet tightly to prevent vibration noise.

🔧 5. Step-by-Step Installation (Mike’s Walkthrough)

Here’s how it unfolded, step by step.

Step 1: Set the Condenser

-

Placed it on the pad, checked level.

-

Anchored it down to prevent shifting.

Step 2: Install the Air Handler

-

Connected to existing supply/return ductwork.

-

Sealed seams with mastic, not just tape.

-

Mounted securely, double-checking airflow.

Step 3: Line Sets

-

Ran pre-insulated copper line set through the wall.

-

Cut and flared ends carefully.

-

Connected with torque wrench to Goodman’s specs.

Step 4: Pressure Test

-

Pressurized lines with nitrogen at 300 PSI.

-

Held pressure for 30 minutes — no drop.

Step 5: Vacuum

-

Pulled down below 500 microns with pump.

-

Held steady, confirming no leaks.

Step 6: Electrical Connections

-

Wired condenser to disconnect and breaker.

-

Wired thermostat (Y, C, R, G, O/B as needed).

-

Checked all grounds.

Step 7: Startup & Charge

-

Released factory charge of R-32 (Goodman units come pre-charged for certain line lengths).

-

Measured superheat and subcool values to confirm proper charge.

-

Adjusted slightly with scale and refrigerant cylinder.

🧯 6. Safety Lessons With R-32

R-32 is efficient, but handling it taught me new respect.

-

Always ventilate when charging — never in a sealed room.

-

Leak detector beats soap bubbles — refrigerant can pool low to the ground.

-

Store cylinders upright, away from heat.

I realized R-32’s mild flammability isn’t something to ignore. Follow safety procedures, period.

🚨 7. Mistakes I Made (So You Don’t Have To)

Here’s me being honest:

-

Wiring mix-up: Didn’t label thermostat wires when disconnecting the old system — had to backtrack.

-

Forgot airflow arrow: Installed filter rack backwards at first.

-

Flare fitting: Almost left one under-tightened, which would have caused a slow leak.

These were fixable, but they cost me hours. Label everything. Double-check connections.

✅ 8. Post-Installation Checks & First Impressions

After powering up, I ran through these checks:

-

Supply vs return temp: 20°F difference (perfect).

-

Noise: Condenser quieter than expected, air handler had slight hum until I tightened screws.

-

Energy draw: Meter showed lower amp draw than my old unit — promising.

First night, the house cooled evenly, and humidity dropped faster than with the old R-410A system.

💡 9. Mike’s Tips for Other Homeowners

-

Don’t skimp on vacuum quality — moisture in the system ruins compressors.

-

Photograph every connection before you cover it up.

-

Have a helper — these units are heavy.

-

Consider hybrid DIY/pro: You can set up pad, duct, and electrical, then hire a pro to do refrigerant handling if you’re nervous.

📅 10. Looking Ahead: Maintenance & Longevity

Installing is just the start. To keep this Goodman running:

-

Replace filters every 1–3 months.

-

Clean coils annually (both indoor and outdoor).

-

Keep condenser area clear of debris.

-

Schedule a professional inspection every 2 years. (Energy.gov AC Maintenance)

Goodman systems, with proper care, should last 15–20 years.

In the next topic we will know more about: SEER2 Simplified: What Efficiency Means for Your Utility Bills