When homeowners shop for a new furnace or air conditioner, they usually focus on the numbers: BTUs, SEER2, AFUE, or tonnage.

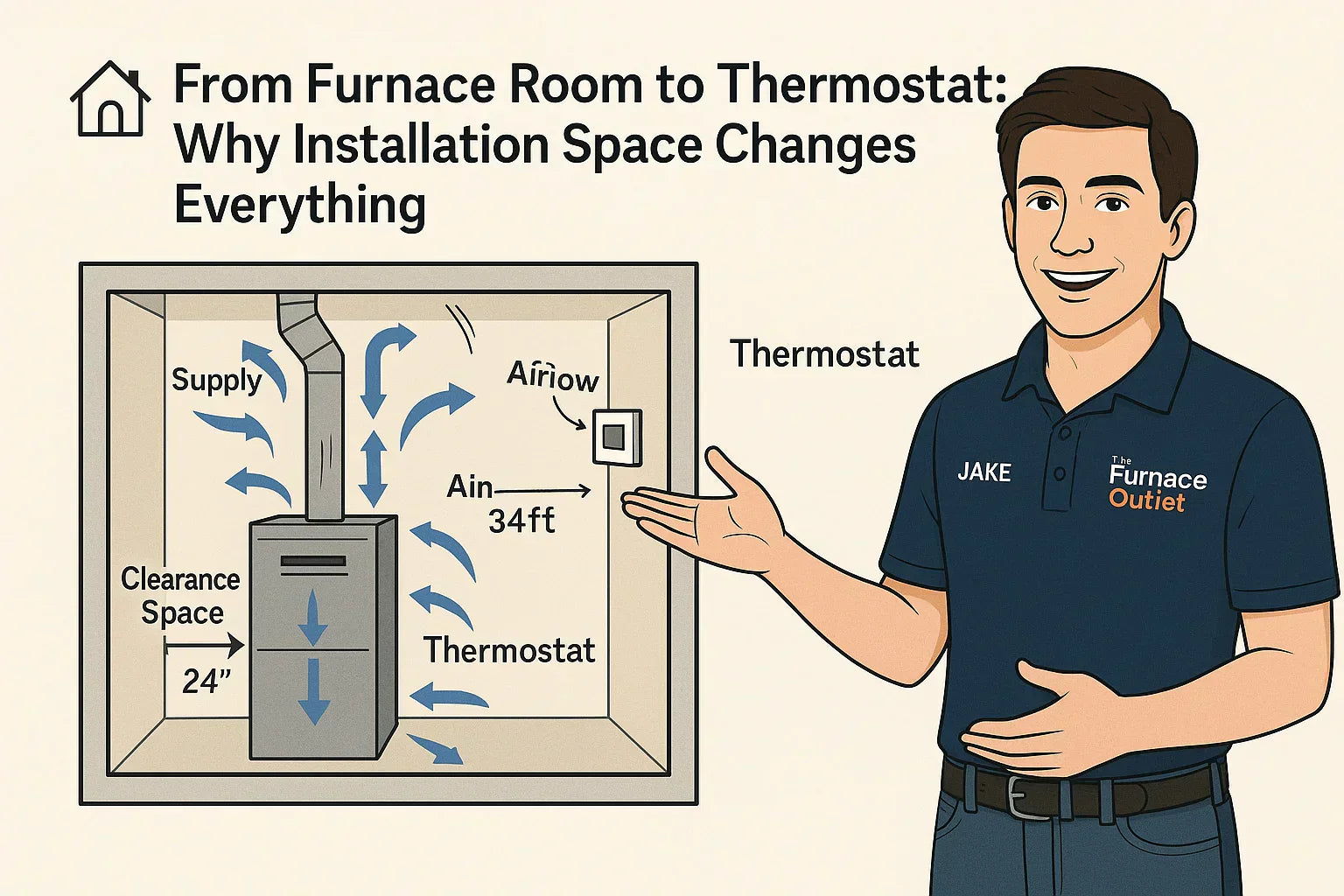

Jake from The Furnace Outlet looks at something else entirely—the space the system will live in.

“You can buy the most efficient equipment in the world,” Jake says, “but if it’s jammed into a closet, starved for air, or baking in an attic, you’ll never get the performance you paid for.”

This article unpacks how the installation environment—from your furnace room to your thermostat location—can make or break your system’s comfort, efficiency, and lifespan.

🧠 1. The Forgotten Variable in System Performance

HVAC systems don’t work in isolation—they’re part of your home’s environment. And that environment directly impacts how efficiently they operate.

Jake explains:

“Your system’s not just reacting to outdoor temperatures—it’s also reacting to what’s around it inside your home.”

If your furnace or air handler is wedged into a tight mechanical closet, surrounded by stored items, or installed in a poorly ventilated space, it’s like trying to breathe through a straw.

The Hidden Cost of a Tight Install

-

Restricted airflow increases blower strain

-

Electronics run hotter, reducing life expectancy

-

Maintenance gets skipped because techs can’t access panels

-

Real efficiency drops 10–20% compared to lab ratings

A 120,000 BTU furnace installed in a 95°F attic won’t deliver the same output as one installed in a 70°F basement.

Airflow, ambient temperature, and service access all determine how many of those rated BTUs you actually feel.

👉 Energy.gov – Proper HVAC Installation Basics

⚙️ 2. Why Clearance Space Matters More Than You Think

Manufacturers list minimum clearance requirements for a reason—and not just for safety. These gaps ensure the blower and heat exchanger can “breathe” freely.

Common Clearance Mistakes Jake Sees

| Location | Mistake | Impact |

|---|---|---|

| Furnace closets | Installed too close to wall | Overheating, poor airflow |

| Air handlers | No top clearance | Coil airflow restriction |

| Basements | Stored boxes blocking return | Increased static pressure |

| Utility rooms | Shared with water heater | Combustion air imbalance |

“If I need to wedge my shoulder between your furnace and a wall to reach the filter,” Jake jokes, “it’s too tight for air to flow right.”

The Rule of Thumb

At least 24 inches of front access and 3 inches on each side should be left open. For top-mounted coils, leave 18 inches above the unit for unrestricted airflow.

🔥 3. Furnace Rooms: Heat Traps or Efficiency Boosters

Your furnace room is more than a storage nook—it’s a microclimate that affects system behavior.

Jake has seen it all:

-

Furnaces surrounded by paint cans and mops.

-

Water heaters sharing tiny closets.

-

Metal duct trunks pressed against uninsulated concrete walls.

Each of these adds resistance, heat buildup, or moisture—all silent efficiency killers.

The Three Common Install Types

A. Open Basement (Ideal)

-

Cool, dry air helps combustion.

-

Plenty of airflow for returns.

-

Easier for service and filter changes.

B. Utility Closet (Acceptable but risky)

-

Must have dedicated air inlets (grilles or louvered doors).

-

Space temperature should stay below 90°F.

-

Noise transfer is common if near living areas.

C. Crawl Space or Attic (Conditional)

-

Prone to moisture and temperature extremes.

-

Needs sealed ducts and insulated lines.

-

Best for mild or dry climates.

Jake’s rule:

“If you wouldn’t want to spend an hour in the room your furnace is in, your furnace doesn’t want to either.”

👉 Energy Star – Furnace Installation Location Tips

🧊 4. Cooling Efficiency: The Air Handler’s Environment

When talking about air conditioning, the air handler or coil location plays just as big a role.

R-32 systems, for example, pack more refrigerant power into smaller coils—great for efficiency, but tough on airflow when space is tight.

Problems in Compact Installations

-

Condensate drains clog due to poor slope.

-

Hot return air recirculates in small closets.

-

Evaporator coils overheat or freeze due to restricted air.

Jake notes:

“R-32 is efficient, but it’s picky—it needs breathing room to do its job.”

Vertical configurations need clear airflow above and below the cabinet, while horizontal installs need side clearance for duct takeoffs and service access.

👉 Daikin – R-32 Airflow Requirements

📏 5. Thermostat Placement: The 3-Foot Rule That Controls Comfort

Even a perfectly installed HVAC system will perform poorly if the thermostat is placed in the wrong spot.

Jake compares it to “putting your car’s temperature sensor under the hood.”

Common Placement Errors

❌ Near windows – direct sunlight skews readings.

❌ Above supply vents – rapid airflow cools it prematurely.

❌ In hallways – air stagnation gives false averages.

❌ Near kitchens – heat from cooking triggers false shutdowns.

The Golden Rules

✅ Mount around 5 feet above floor level.

✅ Keep at least 3 feet away from doors, vents, and exterior walls.

✅ Choose a central interior wall for best average reading.

“A thermostat doesn’t measure the room—it measures the air around it,” Jake says.

“Put it in the wrong air, and it’ll make the wrong call.”

👉 Honeywell – Thermostat Placement Guide

🔄 6. Real Case: The Furnace Closet Fix

A homeowner in Nashville complained that their Goodman GR9S801205DN furnace ran loudly and shut off intermittently. The install looked fine—on paper.

Jake’s inspection revealed:

-

Only 1 inch of clearance on one side.

-

No return air grille for makeup air.

-

Closet door sealed tight to the floor.

When the blower kicked on, static pressure skyrocketed.

Jake’s Fix

-

Cut a 12×24” louvered grille into the closet door for airflow.

-

Sealed leaks between the closet and water heater space.

-

Verified blower speed settings and static pressure (0.48 in WC).

After the adjustment:

✅ Furnace noise dropped 40%.

✅ Heat rise stabilized at 55°F (ideal range 35–65°F).

✅ Efficiency improved roughly 8%.

“Sometimes,” Jake laughs, “you don’t need new equipment—you just need to let it breathe.”

🧮 7. How Installation Space Affects the BTUs You Actually Get

Every restriction, every degree of trapped heat, and every service obstacle reduces effective output.

Jake’s real-world data shows:

| Installation Issue | Estimated Efficiency Loss | Resulting Impact |

|---|---|---|

| Tight furnace closet | 5–10% | 120k BTU unit acts like 108k |

| Hot attic install | 10–15% | 4-ton AC cools like 3.5 tons |

| Poor return air path | 8–12% | Uneven room temperatures |

| No service clearance | 3–5% | Maintenance skipped, lifespan drops |

Jake’s analogy:

“Think of your system as an athlete—it performs best with open space, clean air, and a little breathing room.”

🪜 8. Accessibility = Longevity

Accessibility isn’t just for convenience—it’s a maintenance multiplier.

When Techs Can Reach Everything:

-

Filters get changed on time.

-

Coils get cleaned annually.

-

Motors get lubricated.

-

Drain pans get inspected before they overflow.

When They Can’t:

-

Corners get skipped.

-

Leaks go undetected.

-

Systems run hotter, louder, and less efficiently.

Jake adds:

“I’ve seen 15-year systems in open basements and 7-year failures in closets. The only difference was space.”

🌎 9. Regional Installation Mistakes Jake Sees

Different climates, same problem—space matters everywhere.

| Region | Common Mistake | Long-Term Effect |

|---|---|---|

| Southeast | Air handlers in uninsulated attics | Coil corrosion, humidity issues |

| Midwest | Furnaces jammed in laundry closets | Overheating, noise, tripped safeties |

| Northeast | Damp basements with poor return air | Rusted cabinets, airflow loss |

| Southwest | Outdoor units too close to walls | Reduced airflow, short-cycling compressors |

“Climate doesn’t just change your load—it changes your install strategy,” Jake explains.

💡 10. Jake’s “Breathing Room” Formula

Jake’s quick sizing guide for mechanical room airflow:

For every 1,000 BTUs of system capacity, provide at least 2 square inches of free vent area.

Example:

120,000 BTU furnace → 120 × 2 = 240 sq in of vent opening

That’s roughly a 15×16 grille or two smaller 12×12 vents in the door or wall.

“If your furnace room seals tighter than a refrigerator, it’s suffocating your system.”

He also recommends leaving at least 6 inches of clearance between equipment and stored items—especially around intakes and control panels.

🧰 11. How to Audit Your Installation Space

Jake gives homeowners a quick, no-tools-needed inspection list:

✅ Front Clearance: At least 24” clear for filter and service door access.

✅ Side Clearance: Minimum 3”.

✅ Top Clearance: 18” for vertical air handlers.

✅ Return Air Path: Unobstructed and not shared with combustion gases.

✅ Temperature Check: Room shouldn’t exceed 90°F when running.

✅ Drain Line: Slope away from coil, not toward it.

✅ Noise: Loud airflow = high static pressure = restricted space.

“If it looks cramped, it’s probably costing you money,” Jake says.

🧊 12. How Thermostat & Furnace Placement Work Together

Your thermostat measures temperature where it’s mounted—but your furnace responds to that signal across the entire system.

Poor placement can make your system “chase” phantom readings, leading to uneven heating or cooling.

Example:

A thermostat placed near a return vent reads cooler air faster, shutting the furnace off before rooms warm up. The furnace short-cycles, wasting gas and blower life.

Jake’s advice:

“If your thermostat’s too close to the furnace or return vent, your system will always think it’s done working before it really is.”

He suggests relocating thermostats if consistent room imbalances appear after upgrades or renovations.

🧾 13. Case Study: The Basement Furnace That Couldn’t Keep Up

A family in Pittsburgh installed a new Goodman 4-ton R-32 system with a 120k BTU furnace in their basement. Everything was to code—but the mechanical room had no louvered door, and the return grille was partially blocked by storage boxes.

After a few weeks:

-

Furnace tripped its high-limit switch repeatedly.

-

Cooling coil froze once in summer.

-

Bills climbed 18%.

Jake’s onsite test revealed static pressure of 0.95 in WC—almost double the recommended level.

Fixes

-

Installed vented closet door for makeup air.

-

Cleared storage away from return trunk.

-

Rebalanced airflow with dampers.

Result:

✅ Static pressure dropped to 0.52 in WC.

✅ Furnace stayed within ideal heat rise range.

✅ 15% reduction in gas and electric use.

“Sometimes the best efficiency upgrade is just giving your system space to breathe.”

✅ 14. Jake’s Key Takeaways

-

Installation space = performance space.

-

Cramped installs cut real efficiency by 10–20%.

-

R-32 and high-efficiency systems are more airflow-sensitive than older models.

-

Thermostat placement is part of system design—not an afterthought.

-

Proper clearance, venting, and access extend lifespan and comfort.

Jake’s final thought:

“Your system doesn’t live in a lab. It lives in your home. Give it the right environment, and it’ll pay you back in quiet, steady comfort for years.”

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The 4-Ton Question: How to Know If This System Really Fits Your Home