When most homeowners think about heating and cooling power, they think in BTUs and tons.

Jake from The Furnace Outlet thinks in something else entirely: airflow.

“BTUs tell you what a system could do,” Jake says.

“Airflow tells you what it’s actually doing.”

You can have a 4-ton R-32 system rated for 48,000 BTUs and a 120,000 BTU furnace, but if the ducts can’t move enough air, that power just sits in the equipment—like horsepower trapped in first gear.

👉 The Furnace Outlet – Goodman 4-Ton R-32 System

This guide breaks down why duct design, static pressure, and airflow control—not raw BTU numbers—decide how comfortable your home feels and how efficient your system runs.

🧠 1. Why Airflow Matters More Than BTUs

Every HVAC system is a closed-loop air machine. Air enters through returns, passes the filter and coil, absorbs or releases heat, and moves back through supplies.

If any part of that loop is restricted—undersized ducts, dirty coil, tight filter—the system’s output drops even if its BTU rating looks impressive.

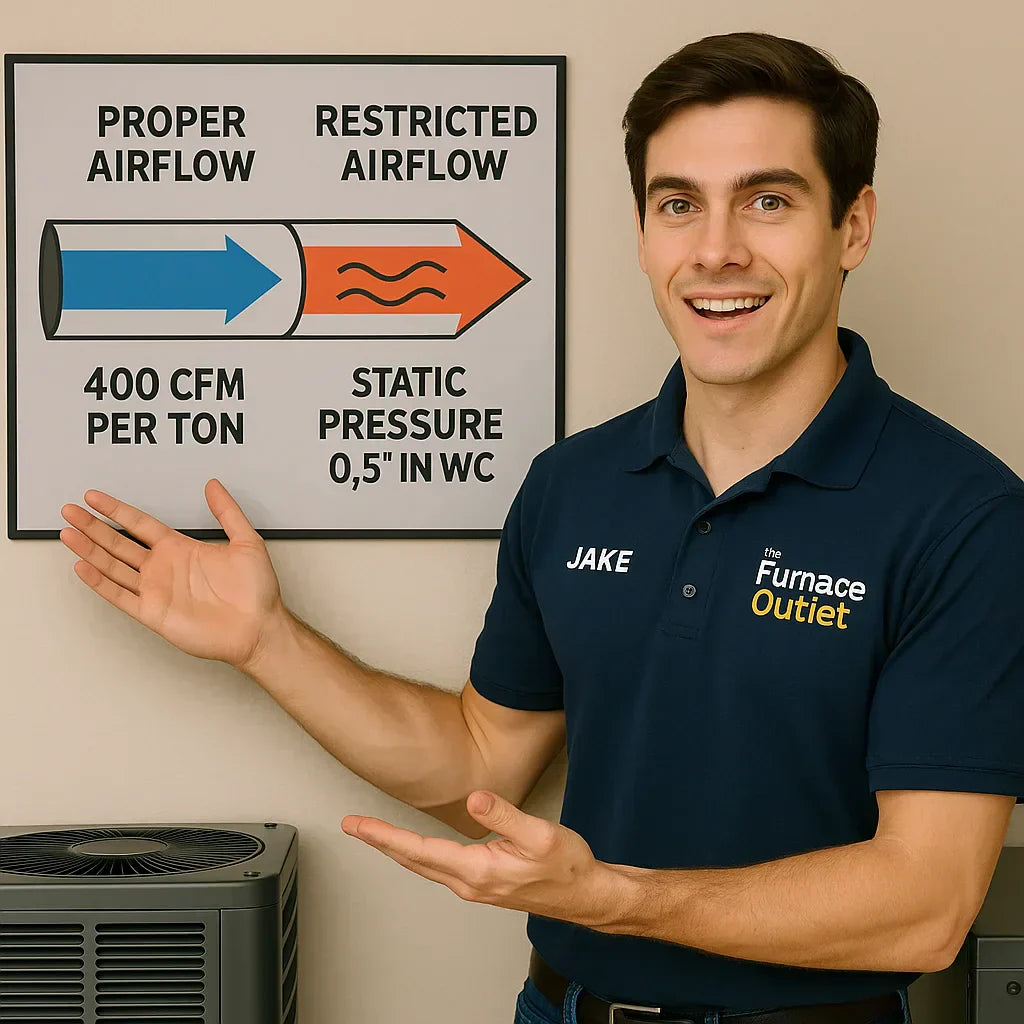

Jake’s baseline rule:

-

Cooling: 400 CFM (cubic feet per minute) of airflow per ton

-

Heating: about 130 CFM per 10,000 BTUs of output

So, a 4-ton system needs 1,600 CFM of cooling airflow, and a 120k BTU furnace needs around 1,500–1,700 CFM for safe combustion heat transfer.

If your ducts can only handle 1,200 CFM, your system will underperform by roughly 25 percent.

👉 Energy.gov – Central Air Conditioning Efficiency Basics

Jake explains it simply:

“Think of airflow as the fuel pump for your system’s horsepower. No air, no performance.”

⚙️ 2. The Ductwork Equation: Static Pressure vs. CFM

When air moves through ducts, fittings, filters, and grilles, it meets resistance—called static pressure, measured in inches of water column (WC).

Your blower works against that resistance.

-

Ideal static pressure: ~0.5 in WC total

-

Too high (> 0.8 in WC): reduced airflow, noise, coil icing

-

Too low (< 0.3 in WC): poor mixing, weak distribution

Jake compares it to a car engine:

“Static pressure is back-pressure. Your blower’s trying to exhale—if the pipes are too small, it strains itself.”

Every elbow, damper, and flexible duct adds friction.

Poorly designed systems can waste hundreds of CFM before air even reaches the registers.

👉 AC Direct – Duct Sizing & Static Pressure Calculator

📏 3. Matching Duct Size to System Size

Jake’s golden rule: size ducts for the air, not just the box.

| System | Airflow (CFM) | Main Trunk (in.) | Return Area (sq in.) |

|---|---|---|---|

| 2.5 ton | 1,000 | 14 × 8 | 200 |

| 3.5 ton | 1,400 | 16 × 8 | 250 |

| 4.0 ton | 1,600 | 18 × 8 | 300 |

| 5.0 ton | 2,000 | 20 × 8 | 350 |

He notes that many existing homes with 4-ton systems still have 16×8 trunks—a bottleneck right at the source.

“That’s like trying to drink a milkshake through a coffee stirrer,” Jake jokes.

“Your blower’s doing cardio, and your house still isn’t cooling evenly.”

🔄 4. What Happens When Airflow Falls Short

Air restriction triggers a domino effect:

On the cooling side:

-

Coil temperature drops below freezing → ice buildup

-

Compressor runs longer → higher energy use

-

SEER2 efficiency plummets

On the heating side:

-

Heat exchanger overheats → safety shutoff

-

Short cycling → fuel waste and component wear

-

Uneven temperatures across rooms

Jake warns that both problems start the same way: “quiet” under-airflow that no one measures until comfort disappears.

👉 Energy Star – Duct Sealing & Efficiency Tips

🧊 5. The 4-Ton Example: Airflow’s Hidden Losses

A 4-ton R-32 condenser like Goodman’s GLXS4BA4810 is rated for 48,000 BTUs at 1,600 CFM.

If high static pressure drops flow to 1,200 CFM, real output falls to about 36,000 BTUs—the equivalent of a 3-ton system.

That means you paid for 4 tons, but you’re cooling like a 3 ton.

Jake says:

“It’s the silent tax on bad ductwork—you lose a ton of cooling, but your power bill doesn’t drop one cent.”

🔥 6. Heating Balance: 120,000 BTUs & Airflow Harmony

Your furnace’s blower must keep the heat exchanger from overheating while also distributing warmth evenly.

If airflow drops below safe limits:

-

The heat exchanger runs too hot.

-

Limit switches trip.

-

The furnace short-cycles.

For a 120 kBTU two-stage unit, target airflow is 1,400–1,800 CFM.

ECM motors ramp automatically, but only within limits; undersized ducts still cap total flow.

Jake’s observation:

“A big furnace isn’t dangerous. Bad airflow is.”

🧩 7. How R-32 Changes the Airflow Game

R-32 refrigerant transfers heat more efficiently than R-410A, but that also means coils are denser and airflow-sensitive.

Restricted flow can raise pressure, overheat compressors, and unbalance the refrigerant circuit.

Jake notes:

“R-32 systems reward good ductwork—but they’ll punish sloppy airflow twice as fast.”

👉 Daikin – R-32 Refrigerant Overview

🪜 8. Simple Fixes That Restore Lost Airflow

You don’t always need to rebuild ducts to gain back CFM. Jake recommends:

✅ Clean coils & blower wheels annually — dirt = friction.

✅ Use low-resistance filters (MERV 8-10 ideal for most homes).

✅ Seal & insulate ducts — leaks waste 20–30% of airflow.

✅ Add return grilles in closed-off rooms.

✅ Check blower speed taps — many are still set too low from the factory.

“Airflow upgrades are the cheapest BTUs you’ll ever buy,” Jake says.

🧮 9. Jake’s DIY Airflow Check

You can verify airflow in 10 minutes:

1️⃣ Remove one supply register cover.

2️⃣ Hold an anemometer (or cheap airflow meter) over the duct.

3️⃣ Record velocity in ft/min (FPM).

4️⃣ Multiply by duct opening area (sq ft) to get CFM.

5️⃣ Add up all registers’ CFMs and compare to your rated airflow.

If your total is < 1,400 CFM on a 4-ton, call a tech to check static pressure and blower speed.

Jake smiles:

“Most houses that ‘need bigger ACs’ really just need better airflow.”

🧾 10. Climate Zones & Airflow Expectations

Just as BTU demand changes by region, so does optimal airflow:

| Climate Zone | Typical Duct Layout | CFM per Ton | Static Target |

|---|---|---|---|

| Hot/Humid (GA, FL) | Long runs, attic ducts | 350 | 0.5 in WC |

| Mixed (TN, VA) | Basement trunks | 375 | 0.45 in WC |

| Cold/Dry (ME, MN) | Short runs, tight homes | 400–425 | 0.4 in WC |

Jake’s logic:

“In humid states, slower air helps pull out moisture. In dry states, faster air spreads heat better.”

👉 DOE – Building America Climate Zones

🧰 11. Duct Design vs. Duct Reality

Even professionally built homes often suffer from:

-

Oversized supply trunks but tiny returns

-

Flex ducts with tight bends

-

Too many branch runs per trunk

-

Missing balancing dampers

Jake’s rule:

“You can’t fix airflow with tonnage. Fix airflow with ductwork.”

He recommends pressure testing after any system replacement—it ensures the shiny new furnace and condenser actually perform to spec.

🧩 12. The Furnace-AC Partnership

Your 120 k BTU furnace and 4-ton R-32 condenser share the same blower.

If ducts are undersized for one mode, both suffer.

When balanced:

-

The furnace maintains even heat rise (35–65 °F).

-

The coil gets full CFM for 14.5 SEER2 efficiency.

-

Humidity stays stable.

Jake calls it “HVAC marriage counseling”—both sides need compromise.

👉 AHRI Directory – Certified System Matches

🧠 13. Oversizing Ducts? Rarely a Problem

Unlike furnaces, ducts can’t really be “too big.”

Slightly oversized ducts reduce noise and static pressure, improving efficiency.

“If in doubt, go larger,” Jake says.

“Air loves space. Electricity and gas bills don’t.”

He adds that future upgrades—like moving from 14.5 to 16 SEER2—will already be supported by the extra duct capacity.

📊 14. Real-World Case: Same System, Different Ducts

| Scenario | Duct Size | Airflow | Cooling Output | Comfort Level |

|---|---|---|---|---|

| Home A | Undersized (16×8) | 1,250 CFM | 36,000 BTU | Hot rooms, loud vents |

| Home B | Proper (18×8) | 1,600 CFM | 48,000 BTU | Even temps, quiet |

| Home C | Upgraded (20×8 + extra return) | 1,800 CFM | 50,000 BTU equiv | Best humidity control |

The equipment never changed—only airflow did.

Jake concludes:

“You can gain a whole ton of cooling just by letting the system breathe.”

🧮 15. Jake’s “Airflow-First” Sizing Formula

1️⃣ Find your total BTU output.

Cooling BTUs ÷ 12,000 = Tons.

2️⃣ Multiply by airflow factor (CFM/ton) based on climate:

- Humid: 350

- Mixed: 375

- Dry: 400

3️⃣ Add 10 % for static pressure > 0.6 in WC.

4️⃣ Verify return area ≥ CFM / 5.

Example:

4 tons × 400 CFM = 1,600 CFM → needs ≥ 320 sq in return.

Jake calls it his “back-of-clipboard math”—good enough to catch most design issues before they start.

💡 16. How Poor Airflow Impacts Energy Bills

Restricted ducts force the blower to work harder and longer:

-

Each 0.1 in WC increase adds ~10 % power draw.

-

Coil efficiency drops as air velocity falls below target.

-

Heating cycles lengthen, wasting gas.

That’s why airflow tuning can cut bills by 10–20 % without replacing equipment.

“It’s the HVAC version of a tune-up,” Jake says.

“Same engine, better breathing.”

🧾 17. Quick Audit Checklist for Homeowners

✅ Filter size and cleanliness

✅ Duct insulation intact

✅ Supply and return vents unobstructed

✅ Static pressure test (< 0.6 in WC)

✅ Measured CFM per ton within 10 % of spec

✅ AHRI match verified

If two or more fail, airflow—not tonnage—is your comfort problem.

🧠 18. Jake’s Golden Rule

“You don’t size systems by BTUs—you size them by breath.”

He reminds readers that airflow is the bridge between efficiency and comfort.

The smartest installations start with ducts, not equipment.

And when you pair the right duct design with modern R-32 and two-stage furnace tech, your 4-ton system will run quieter, cleaner, and cooler than ever.

✅ 19. Key Takeaways

-

Airflow = actual comfort. BTUs just describe potential.

-

Ducts dictate performance. Undersized ducts waste 20–30 % efficiency.

-

Aim for 400 CFM per ton (adjust for humidity).

-

Static pressure ≤ 0.5 in WC keeps noise and wear down.

-

R-32 systems need precision airflow for top efficiency.

-

Bigger ducts rarely hurt—bad airflow always does.

Jake’s final thought:

“Your system doesn’t care how many BTUs it has—it cares how easily it can breathe.”

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: Manual J Without the Math: Jake’s Quick DIY Load Check