A Weil-McLain cast iron boiler is built like a tank. Many of these units last 30 years or more—some even push past 50. But here’s the catch: they don’t get there by accident.

👉 The secret to long life? Regular maintenance.

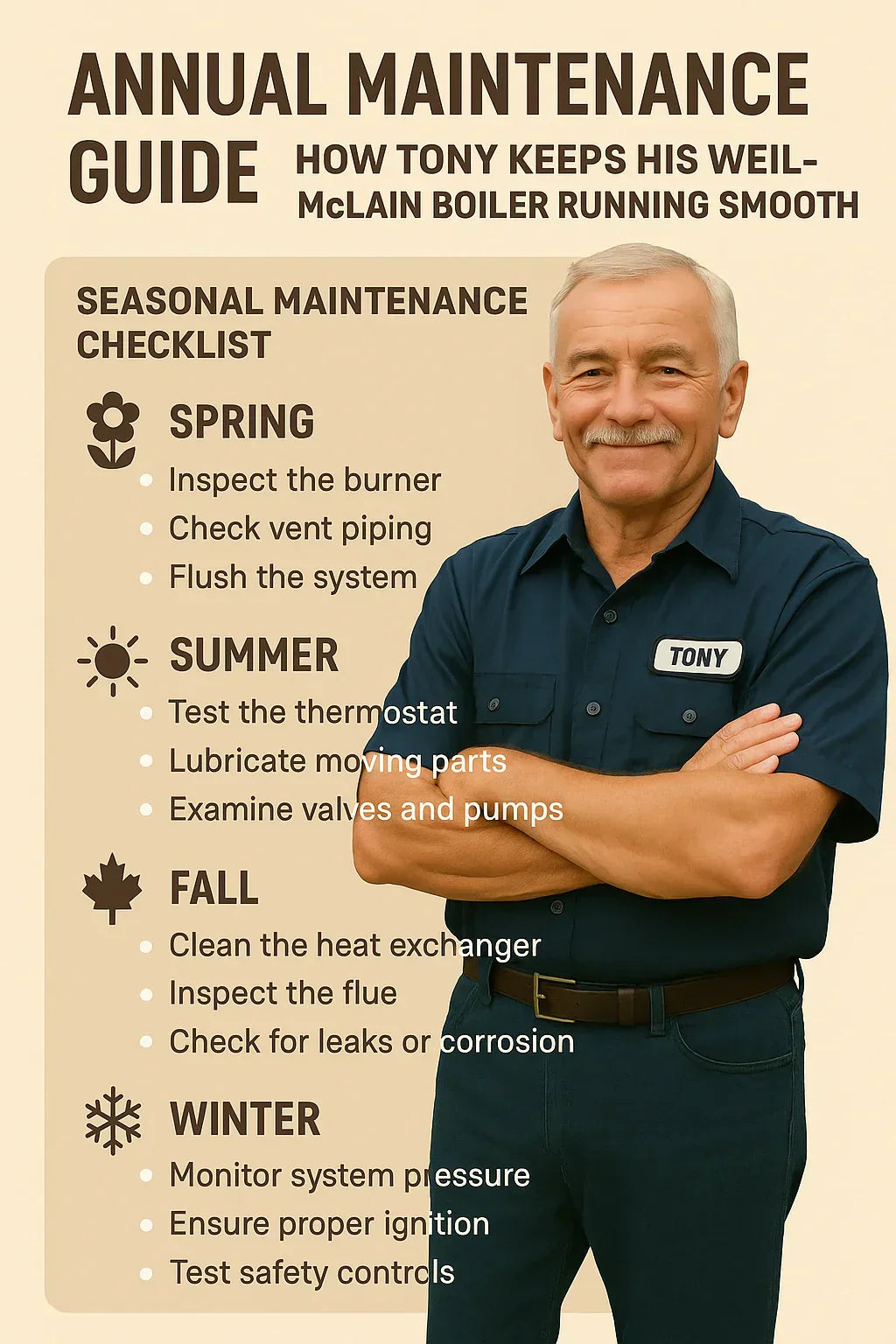

I’m Tony, and I’ve had a Weil-McLain boiler keeping my family warm through New York winters for years. I can tell you from experience: a little yearly attention saves you thousands down the road. In this guide, I’ll share my complete seasonal and annual maintenance routine, what you can DIY, when to call a pro, and what it costs in 2025.

📅 Why Annual Maintenance Matters

Skipping boiler maintenance is like never changing the oil in your car—it’ll run for a while, but eventually, you’ll pay the price.

Here’s what regular maintenance delivers:

-

Longer lifespan – Well-cared-for cast iron boilers easily last 30+ years.

-

Better efficiency – A clean, tuned boiler burns less fuel, cutting gas bills.

-

Fewer breakdowns – Small problems caught early = no emergency service at midnight in January.

-

Safety – Annual checks ensure venting, gas lines, and controls are working properly.

📖 Reference: U.S. Department of Energy – Boilers and Radiators

👉 My rule? “Spend a couple hundred on maintenance to avoid spending a couple thousand on repairs.”

🧹 Seasonal Cleaning Tasks

These are quick, simple jobs I handle myself throughout the year:

-

Dust & vacuum around the unit: Keeps airflow clear and reduces fire hazards.

-

Check intake and exhaust vents: Blocked vents = dangerous carbon monoxide buildup.

-

Keep boiler area clear: No paint cans, boxes, or clutter near the boiler.

👉 I’ve seen neighbors lose efficiency just because cardboard boxes blocked air circulation. It’s simple housekeeping that makes a difference.

📖 Reference: Energy.gov – Heat Distribution Systems

🔍 Annual Inspection Checklist

Every fall, before the heating season, I either perform or schedule a full inspection.

What gets checked:

-

Leaks, corrosion, or cracks in cast iron sections

-

Gas connections for tightness

-

Burner flame – steady blue flame = efficient combustion

-

Pressure & temperature gauges – safe operating levels

-

Vent damper – opens/closes properly to prevent heat loss

👉 My technician once caught a tiny leak near the circulator that would’ve become a major flood mid-winter. A $150 service call saved me $1,500.

📖 Reference: HeatingHelp – Boiler Maintenance

💧 Water Quality & System Flushing

Water inside your hydronic system can make or break your boiler’s life.

-

Poor water quality (oxygen, minerals, sludge) = corrosion and scaling

-

Flushing annually removes sediment that clogs pipes and circulators

-

Water treatment may be recommended in areas with hard water

👉 I skipped flushing once. The next year, my circulator pump seized. Lesson learned: I flush every spring now.

📖 Reference: Weil-McLain – Protecting Boilers from Hard Water

🔧 DIY Tasks Homeowners Can Handle

There are plenty of tasks I recommend homeowners do themselves:

-

Bleed radiators: Get rid of trapped air for even heating.

-

Check thermostat batteries & settings: Prevent mid-season “dead thermostat” panic.

-

Inspect pressure gauge: Normal range = 12–15 psi for most systems.

👉 I walk the house each fall bleeding radiators—it takes 20 minutes and keeps the system balanced.

📖 Reference: Family Handyman – How to Bleed a Radiator

👷 Tasks Best Left to Pros

Some things are worth paying a licensed pro for:

-

Combustion analysis & tuning: Requires specialized tools.

-

Gas valve adjustments: Safety-critical, not a DIY job.

-

Safety control checks: Low-water cutoff, pressure relief valve, etc.

-

Chimney/vent inspections: Prevents carbon monoxide hazards.

👉 I handle the basics, but I always schedule a professional tune-up each fall. Peace of mind is worth the $200.

📖 Reference: Boiler Service Costs

🧾 Maintenance Costs in 2025

Here’s what you can expect:

| Task | Cost | Notes |

|---|---|---|

| DIY cleaning/bleeding | Free | Just your time |

| Professional inspection & tune-up | $150 – $300 | Annual must-do |

| System flushing | $200 – $500 | Every 1–2 years |

| Water treatment | $150 – $400 | Depends on local water |

| Emergency service | $250 – $500+ | Avoidable with maintenance |

👉 Think of maintenance as “cheap insurance.” I’d rather pay $250 once a year than $2,500 for an emergency replacement part in the middle of winter.

📆 Tony’s Seasonal Routine

Here’s how I structure my year:

-

Fall: Full inspection & pro tune-up before heating season.

-

Winter: Quick monthly pressure/temp checks; visual leak scan.

-

Spring: Flush system, bleed radiators, schedule chimney cleaning.

-

Summer: Shut down boiler (if not used for hot water), clean around it, check for rust.

👉 My system has been running strong for 8+ years with this routine—no major repairs yet.

📊 Maintenance vs. Neglect: The Payoff

| Approach | Average Lifespan | Efficiency | Repair Costs |

|---|---|---|---|

| Regular Maintenance | 30–40 years | 80–85% steady | Low ($150–$500/year) |

| Neglected System | 15–20 years | Drops to 65–70% | High (repairs $1,000+ often) |

✅ Tony’s Final Word

Here’s my bottom line:

-

Cast iron boilers are tough, but not invincible.

-

A couple hours of care each year keeps them running at peak performance.

-

Don’t cut corners—maintenance saves money and stress.

"Cast iron boilers like my Weil-McLain are workhorses, but they’re not set-and-forget. A couple hours a year keeps it running like new—and saves you headaches in January."

In the next topic we will know more about: Efficiency Ratings Explained: What AFUE Really Means for Boilers