🧠 The Invisible Problem: When Your Furnace Can’t Breathe

Imagine running a marathon while breathing through a coffee stirrer. That’s what your furnace feels like when the duct system is too small, too restrictive, or too dirty.

A Goodman 20 kW electric furnace is designed to move 2,000 CFM (cubic feet per minute) of air through your ducts. If it can’t, you’ll experience:

-

Uneven room temperatures

-

Whistling vents

-

Overheating and short cycling

-

Higher utility bills

“Airflow isn’t a side effect — it’s the foundation of comfort.” — Savvy

⚙️ Step 1: What Airflow Really Is — CFM in Plain English

CFM (Cubic Feet per Minute) measures the volume of air your system moves.

Think of it like a bloodstream: CFM carries the heat your furnace produces to every room in your home.

The Goodman 68,240 BTU (20 kW) system needs 2,000 CFM to perform at peak efficiency. That’s roughly equivalent to filling a small bedroom with air every minute.

External link: Energy.gov – Understanding Air Duct Efficiency

If airflow drops even 10–15%, you’ll start losing heating output, and your system will compensate by running longer — wasting electricity and wearing down components faster.

💡 Savvy tip: You don’t feel BTUs. You feel CFM.

📏 Step 2: Duct Size — Why Bigger (and Smoother) Is Better

Ductwork is your system’s highway. And like any highway, traffic slows down when it’s too narrow.

Here’s a quick rule of thumb for airflow capacity:

| Round Duct Diameter | Approximate CFM Capacity |

|---|---|

| 6” | 100 CFM |

| 8” | 200 CFM |

| 10” | 400 CFM |

| 12” | 600 CFM |

A furnace pushing 2,000 CFM through undersized ducts creates air resistance, or what pros call “static pressure.”

Example:

A 16"x8" rectangular main trunk or 14" round duct can comfortably carry 2,000 CFM.

Drop that to a 12"x8" trunk, and you’ve created a traffic jam.

External link: ACCA Manual D – Residential Duct Design Guide

🧰 Savvy insight: Most airflow issues aren’t furnace problems — they’re duct problems.

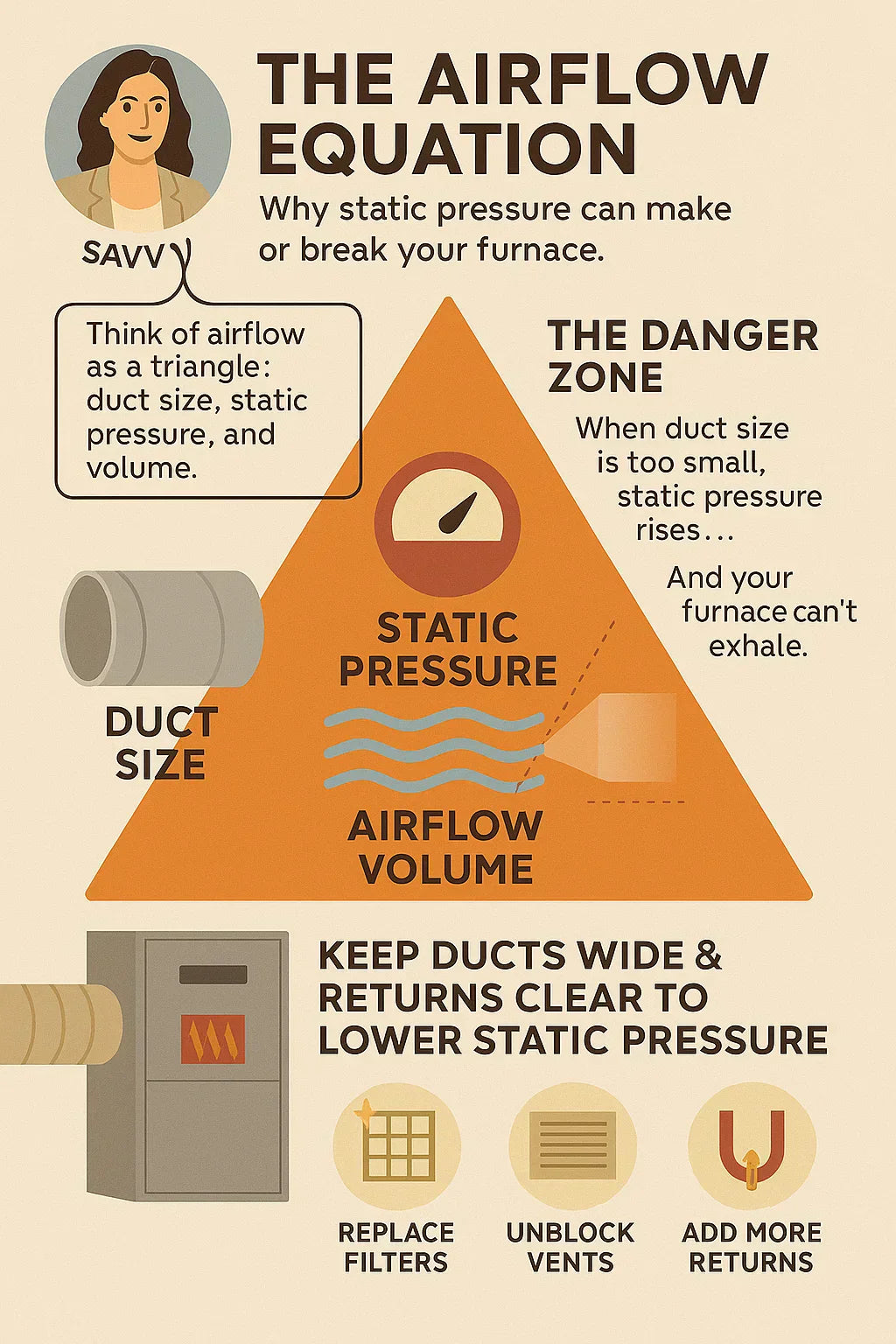

🌀 Step 3: Static Pressure — The Hidden Enemy of Efficiency

Static pressure is the resistance your blower faces when moving air.

It’s measured in inches of water column (“in. WC”), and ideal residential systems operate between 0.3 and 0.5 in. WC.

Above 0.7 in. WC, your system starts suffocating.

-

Airflow drops 15–25%

-

Blower energy use spikes

-

Coils overheat or freeze

In extreme cases, your furnace’s safety switch trips because the blower can’t expel heat fast enough.

⚠️ Savvy warning: High static pressure kills furnaces faster than age ever will.

🌬️ Step 4: How Restriction Creeps In

You might think ducts are clear pipes. In reality, they accumulate resistance over time.

Here’s what chokes airflow:

-

Dirty filters

-

Collapsed flex duct sections

-

Poorly sealed joints

-

Closed registers

-

Dusty blower wheels

Each small blockage adds friction. Combined, they can increase total system pressure by 0.1–0.3 in. WC — enough to cut performance by 20% or more.

External link: ENERGY STAR – Airflow Efficiency Basics

🔥 Step 5: The Goodman Example — Power Meets Pressure Balance

The Goodman 20 kW Electric Furnace has a blower precisely matched to its heating coil capacity.

When ducts are sized correctly, the system maintains:

-

Smooth 2,000 CFM airflow

-

120–140°F supply air temperature

-

Even warmth without hot spots

But if ducts are too small or restrictive, the coil overheats. The limit switch shuts the unit down prematurely — a cycle known as “high-limit tripping.”

Internal link: [The Goldilocks Principle of Heating Power — Finding the Furnace That’s Just Right for Your Square Footage]

🧩 Step 6: The Perfect Balance — Supply vs. Return

For every cubic foot of air your furnace pushes out, it must pull one back in.

That’s why return ducts are just as important as supply ducts.

The general rule:

1 sq. inch of return grille area per 2 CFM of airflow

For a 2,000 CFM furnace:

That’s roughly two 20x25 returns or several smaller ones distributed through the home.

Insufficient return area is like trying to inhale through a pinhole.

🫁 Savvy analogy: Your furnace breathes in through returns and exhales through supplies — both must stay open and clear.

📉 Step 7: The Domino Effect of High Static Pressure

When static pressure rises:

-

Blower motor amps increase

-

System efficiency decreases

-

Noise levels climb

-

Heating elements overheat

Every 0.1 in. WC over the ideal range can increase blower energy use by about 5% and reduce airflow up to 10%.

External link: ASHRAE – Duct Design and Pressure Loss Fundamentals

At 0.8 in. WC, you’re essentially running your furnace on “half lungs.”

🧱 Step 8: Undersized Ducts — The #1 Comfort Killer

Let’s put numbers to it.

| System Airflow (CFM) | Proper Main Trunk Size | If Undersized To… | Result |

|---|---|---|---|

| 2,000 | 16"x8" | 14"x8" | Static +0.15 in. WC |

| 2,000 | 16"x8" | 12"x8" | Static +0.35 in. WC |

| 2,000 | 16"x8" | 10"x8" | Static +0.6 in. WC (system failure likely) |

That last scenario cuts airflow by 30–40%, which forces longer runtimes and may even void your warranty.

⚙️ Savvy note: Ductwork isn’t decoration — it’s a precision tool. Treat it like one.

🧮 Step 9: How to Check Airflow — The DIY Way

You don’t need fancy gauges to notice a problem.

Savvy’s quick tissue test:

-

Hold a tissue near each vent.

-

If it flutters lightly, airflow is good.

-

If it barely moves — or one room feels still — you have a blockage or design flaw.

Bonus: Listen for high-pitched “whistling” sounds when the system runs — that’s static pressure in action.

💡 Step 10: The Air Filter Effect — When Clean Becomes Constrictive

Many homeowners upgrade to high-MERV filters for cleaner air, but not all systems can handle the resistance.

A MERV 13 filter can add 0.15–0.25 in. WC of pressure, choking airflow by 10–20%.

Most standard residential systems perform best with MERV 8–11 filters.

External link: Energy.gov – Furnace Filters and Airflow Efficiency

💬 Savvy tip: Clean air is great. But airflow comes first.

🔧 Step 11: Fixing Airflow the Smart Way

If your furnace sounds like it’s straining, it probably is. Here’s how to help it breathe easier:

✅ Add Return Grilles: More air in = less restriction.

✅ Enlarge Main Trunks: Go from 14"x8" to 16"x8" if airflow exceeds 1,500 CFM.

✅ Straighten Flex Ducts: Keep them taut, not coiled.

✅ Seal Leaks with Mastic: Duct tape isn’t enough.

✅ Schedule a Static Pressure Test: HVAC pros use a manometer to measure and balance system pressure precisely.

External link: Energy.gov – Duct Sealing & Maintenance

🧰 Savvy reminder: A system that moves air freely burns less energy, runs quieter, and lasts longer.

🌬️ Step 12: Variable-Speed Blowers — The Self-Adjusting Solution

Modern systems like Goodman’s variable-speed motors can adjust fan RPM to overcome duct resistance automatically.

Benefits:

-

Consistent comfort despite minor duct issues

-

Lower noise levels

-

Better humidity control

While they can’t fix bad duct design entirely, they provide breathing room (literally) for older or complex layouts.

Internal link: [From CFM to Comfort — How Airflow Shapes Heating Performance]

📈 Step 13: The ROI of Proper Airflow

Here’s what professional duct optimization can achieve:

-

10–20% improvement in efficiency

-

25% quieter operation

-

Longer blower lifespan

-

Even room-to-room temperatures

According to ENERGY STAR’s HVAC Optimization Guide, improving airflow can save up to $200–$400 per year on electric heating systems like the Goodman 20 kW model.

🧩 Savvy insight: The most affordable upgrade in HVAC isn’t more kilowatts — it’s fewer restrictions.

🧭 Step 14: Real-World Example — The Choked System

Case Study:

A homeowner installs a 20 kW Goodman furnace in a 1,600 sq. ft. home. But their main trunk is undersized at 12"x8" and uses flexible ducting with sharp bends.

Results:

-

Static pressure measured at 0.82 in. WC

-

Actual airflow: 1,580 CFM (21% below rated)

-

Rooms furthest from the unit: 4–6°F cooler

After resizing ducts to 16"x8" and sealing joints:

-

Static pressure drops to 0.47 in. WC

-

Airflow restored to 2,010 CFM

-

Runtime reduced by 22%

-

Noise levels cut nearly in half

“The furnace didn’t change — the ductwork did. Comfort followed.” — Savvy

🔋 Step 15: Static Pressure & Energy Use — The Hidden Cost Curve

The harder your blower works, the more power it draws.

For every 0.1 in. WC increase in static pressure:

-

Blower wattage climbs ~5–7%

-

Total system efficiency drops 3–5%

That’s why electric furnaces paired with poor airflow often appear “expensive to run” — not because of the heating elements, but because of airflow resistance.

External link: ASHRAE – Air Distribution and Fan Power Research

🧱 Step 16: When Ducts Need a Redesign

You might need professional help if you notice:

-

Rooms with weak airflow

-

Loud vent noise or high fan speeds

-

Furnace overheating frequently

-

Short heating cycles

A duct redesign typically costs $500–$1,000 — but it restores full system performance, lowers runtime, and extends your furnace’s lifespan.

🧠 Savvy takeaway: Airflow design is 80% of system performance. Equipment is only the other 20%.

🪶 Step 17: Common Airflow Myths (Busted)

Myth #1: Closing vents saves energy.

False — it increases static pressure and forces air through leaks.

Myth #2: High-MERV filters are always better.

Not without proper duct sizing. They can choke airflow.

Myth #3: Bigger ducts mean wasted energy.

Oversized ducts reduce pressure, not efficiency.

Myth #4: New furnaces fix airflow problems.

Not unless you fix the ducts too.

External link: ENERGY STAR – Airflow & HVAC Myths

🧩 Step 18: Savvy’s Comfort Blueprint — The Airflow Equation

To calculate ideal duct performance for your furnace:

Where ΔT = temperature rise (supply air minus return air).

For Goodman’s 68,240 BTU model with a 35°F rise:

Right in the 2,000 CFM sweet spot.

“Perfect airflow isn’t magic — it’s math that moves.” — Savvy

🏁 Step 19: Final Thoughts — Let Your Furnace Breathe

You can’t see airflow, but you can feel its impact every time your home heats unevenly or your furnace sounds strained.

The Goodman 20 kW electric furnace delivers power, but duct design delivers comfort.

“Heat is only as good as the air that carries it.” — Savvy

Before you blame your furnace for inefficiency, check its lungs — the ducts. Because in HVAC, comfort isn’t about how much power you buy; it’s about how smoothly that power flows.

Buy this on Amazon at: https://amzn.to/4nvQIts

In the next topic we will know more about: Sizing for Add-Ons — How to Plan for Future Rooms, Basements, or Home Offices Without Replacing Your Furnace