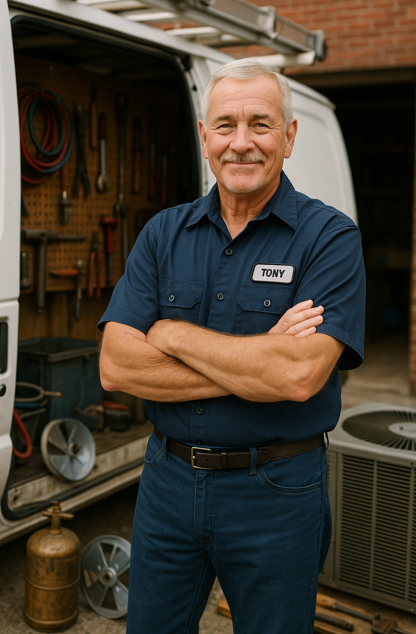

Tony Marino here—your seasoned HVAC pro, with years of hands-on experience in residential and commercial systems. Warehouses pose special challenges for cooling: huge spaces, high ceilings, varied load patterns, and airflow headaches. If you’re looking into warehouse AC units, air conditioning for warehouses, or serious warehouse HVAC, you’re not just dealing with “bigger home AC.” You’re in a different league.

Today, I want to talk through what it really takes to cool a warehouse, where some common mistakes come in, and a case for using a Goodman 3‑Ton 14.5 SEER2 R‑32 system in certain warehouse setups. Let’s be crystal clear: this isn’t a one-size-fits-all, but in some warehouse scenarios, a system like this could deliver strong value, control, and performance.

1. What Makes Warehouse Cooling So Different

Cooling a warehouse isn’t like cooling a house. There are a lot more variables, and the stakes are higher when you guess wrong.

A. Massive Volume & High Ceilings

Many warehouses have very high ceilings. That’s extra air volume to cool, which means the BTU requirement is not just based on floor space. According to industry data, typical warehouse HVAC systems can require 30,000 to 100,000+ BTUs, depending on size, ceiling height, insulation, and load. (longacreco.com)

B. Ventilation & Air Changes

Warehouses often need significant airflow to keep air quality acceptable. According to ventilation design experts, warehouses may require 6–30 air changes per hour based on space use, stored goods, and occupancy. (Supply & Demand Chain Executive) That means your HVAC system has to handle not just sensible heat from hot air, but constant fresh-air mixing.

C. Heat Sources Inside the Space

Warehouses aren’t empty boxes. You’ve got:

-

Lighting (often high-output LED or industrial lighting)

-

Machinery or material-handling equipment generating heat

-

People, sometimes in concentrated zones

-

Dock doors opening and closing, which causes infiltration (uncontrolled outside air) (Wikipedia)

All of that adds to the cooling load. You can’t ignore it.

D. Air Stratification

Warm air rises. In a warehouse with tall ceilings, conditioned air can pool up high while the floor remains warm and uncomfortable. Without airflow management (like destratification fans), your AC will be fighting a losing battle. (HVAC Jack)

E. Efficiency & Zoning

Because of the huge space, zoning is essential. Different parts of a warehouse operate with different cooling needs: offices, dock areas, storage aisles, etc. Proper HVAC design for warehouses often splits the load into zones to avoid overcooling some parts while neglecting others. (ProCalcs)

2. Common Types of Warehouse Air Conditioning Units

When people talk about warehouse AC, they usually mean one (or a combination) of these:

-

Rooftop Package Units — Heavy-duty, self-contained, designed for large commercial buildings.

-

Split Systems — Condenser outside + air handler inside. More flexible if you already have ductwork or want to retrofit.

-

Portable AC Units / Spot Cooling — For smaller zones, dock areas, or localized cooling.

-

Ductless / Mini‑Splits — Great for add-on zones or areas without ductwork, but scaling across a big warehouse is expensive or complex.

Each option has pros and tradeoffs, especially in cost, efficiency, and install complexity.

3. Why Consider the Goodman 3‑Ton 14.5 SEER2 R‑32 Bundle for a Warehouse

Now, let me make the case (my Tony-style case) for using the Goodman 3‑Ton 14.5 SEER2 R‑32 bundle in a warehouse context. Yes — a 3-ton system is relatively small for a warehouse, but hear me out: there are real scenarios where it works, or at least partially works, and can be a smarter path than you think.

Here’s what this Goodman system brings to the table:

-

Matched Condenser + Air Handler / Coil — This is a real split system; not just a condenser, but a matched indoor component. That means better refrigerant flow, fewer compatibility issues, and more reliable performance.

-

14.5 SEER2 Efficiency — While not ultra-premium, this rating is solid. In a warehouse scenario where loads can spike, it gives a good efficiency return for the investment.

-

R-32 Refrigerant — Cleaner, more modern refrigerant that helps with environmental compliance and future serviceability.

-

Flexible Installation — Depending on your layout, the air handler (or coil) can be integrated into part of your duct network or used as part of a zone add-on.

4. Real-World Warehouse Scenarios Where This Goodman Bundle Makes Sense

Here are a few examples — from Tony Marino’s “what I see in the field” — where a 3-ton Goodman unit *could actually be a reasonable warehouse AC solution:

Scenario A: Medium-Sized Warehouse Office / Work Area

-

You have a warehouse (say, 4,000–6,000 sq ft) but only need to condition a portion of it — an office wing, a mezzanine, or a small workshop area.

-

Rather than install a massive rooftop system, you run a 3-ton split: condenser outside, air handler tied into ducts in that workspace.

-

This gives you dedicated cooling where people work, without overcooling the storage racks.

Tony’s Verdict: Very smart. You’re targeting your cooling where it matters, and not paying for a huge commercial HVAC package for an entire open-bay floor.

Scenario B: Add-On Cooling for a High-Heat Corner

-

Your warehouse has a “hot spot” — maybe a loading dock, or an area near machinery where heat builds up.

-

You add the Goodman system as a “zone” just to serve that area, using its condenser and a separate coil or duct run, possibly with a dedicated thermostat.

-

Because it’s a split system, you’re not just running a fan or portable cooler — you have real, conditioned airflow.

Tony’s Verdict: Efficient and useful. Using a 3‑ton split for a hot zone gives you control without turning your whole industrial HVAC into a 20+ ton beast.

Scenario C: Small Warehouse or Light Industrial Space

-

The warehouse is fairly compact, or the ceiling height is moderate (not 40ft+).

-

Insulation is decent, and your cooling loads are more “light industrial” than heavy.

-

You run the Goodman system, maybe with additional destratification fans to handle air mixing, and you get reliable, year-round comfort.

Tony’s Verdict: In a “small warehouse” or flex space, a 3-ton unit might be more feasible than you think. But design is everything — you need load calc, airflow, and a good plan.

5. What Could Go Wrong (Tony’s Cautionary Notes)

I’m not here to sugarcoat: using a 3-ton central AC in a warehouse is not always the right answer. Here’s where mistakes happen:

-

Undersizing Risk: If you underestimate the warehouse load (ceiling height, heat gain, occupancy), a 3-ton system might struggle and run all day.

-

Poor Airflow Design: Without proper duct design, destratification fans, or zoning, cool air may never reach the floor, or warm air may pool up top.

-

Ventilation Imbalance: Warehouses often need large volumes of fresh air. If your HVAC setup doesn’t account for that, things get stale, or your system fights pressure issues. (Supply & Demand Chain Executive)

-

Insulation and Infiltration: If walls, roof, or dock doors are poorly insulated, you’ll lose a lot of your cooling to leakage.

-

Energy Costs: Even a well-sized 3-ton system in a warehouse has to run hard at times, especially if heat load is high. Without efficiency planning and zoning, your electric bill could hurt.

-

Maintenance Challenges: Commercial or warehouse systems demand more maintenance. Dirty filters, coil fouling, and lack of airflow balance can degrade performance rapidly.

6. Best Practices for Warehouse AC Design (Tony’s Pro Tips)

If you’re seriously considering a warehouse AC unit, especially with a central split like the Goodman bundle, here’s what I always recommend (Tony-style):

-

Run a Full Load Calculation

Use a real HVAC pro or engineer. Don’t guess. Use a Manual J or commercial load method that accounts for your walls, roof, internal heat, and ventilation needs. -

Design for Proper Ventilation

Use ASHRAE guidelines for air changes. Make sure supply and exhaust are balanced. Negative or positive pressure can ruin system performance. -

Include Destratification

Use ceiling or high-volume low-speed (HVLS) fans to mix air. That keeps temperatures even and prevents warm air from hiding at the ceiling. -

Zone Smartly

Break down your warehouse into zones: working areas, storage aisles, dock zones. Use dampers or separate handlers so you’re not cooling everywhere all the time. -

Insulate Well

Insulate roof decks, walls, and particularly roll-up doors. When you minimize thermal gains, your AC doesn’t have to fight so hard. -

Filter & Vent Correctly

Use filters if needed, especially if dust or pollutants are present. Also, plan for makeup air if you’re exhausting a lot. -

Plan Maintenance

Schedule regular coil cleaning, refrigerant checks, and airflow balancing. Warehouse systems are workhorses — treat them like it.

7. Why the Goodman 3‑Ton Bundle Might Be Under-Estimated in a Warehouse

Here’s something I don’t think enough people give credit to: smaller central split systems like this one are more flexible than people realize.

-

They can serve a partial zone effectively without forcing you into giant rooftop units.

-

They're easier to install in retrofits or smaller industrial spaces where running ductwork is feasible.

-

The R-32 refrigerant helps with efficiency, so if you’re not absolutely cranking that system 24/7, it can be cost-effective.

-

Because it’s a matched system, you avoid some of the reliability and efficiency issues that come with mismatched or jury-rigged evaporator / condenser combos.

8. When You Should Probably Pass on a 3‑Ton and Go Bigger (Or Another Way)

That said — there are absolutely warehouse scenarios where this bundle is the wrong tool. Here’s when you should probably go another route:

-

Your warehouse is very large (tens of thousands of square feet) — you’ll need many more tons.

-

Ceiling height is extremely tall (30 ft+), and you don’t have destratification or airflow design.

-

Internal heat loads are enormous (heavy machinery, high-watt lighting, dock heat, etc.).

-

You don’t have ductwork, and installing it isn’t cost-effective — you may need packaged rooftop units or multiple mini-splits.

-

Your budget supports a full commercial HVAC design with zoning, heat recovery, and high-capacity systems.

9. Tony’s Bottom Line

Here’s where I land, after walking through all the trade‑offs, design challenges, and real-world use cases:

-

If you’re planning to condition only part of your warehouse — like a workspace, mezzanine, or office area — the Goodman 3‑Ton 14.5 SEER2 R‑32 bundle is absolutely worth considering.

-

For full, large-scale warehouse cooling, this is likely underpowered, and you’re better off with a commercial-grade rooftop or multi-ton system.

-

Whatever you do: don’t skip the load calculation. Don’t skimp on ventilation design. Invest in destratification.

-

Use the flexibility, efficiency, and matching of this Goodman bundle to deliver real-world value — but don’t assume “tons small = cheap or easy.”