You’ve probably heard of SEER2 — the new efficiency standard that replaced SEER starting in 2023. But what most folks don’t realize is why the change happened. It wasn’t just about stricter regulations. It was about making testing more realistic by accounting for something every HVAC system deals with: external static pressure (ESP).

If your HVAC system has ductwork — and most do — static pressure is affecting how much air your system can move, how efficiently it cools or heats, and how much you're paying on your utility bills. And now, SEER2 ratings reflect that.

Let’s break down what ESP actually is, how it’s measured, why SEER2 includes it, and what it means for your comfort, equipment, and energy savings.

What Is External Static Pressure (ESP)?

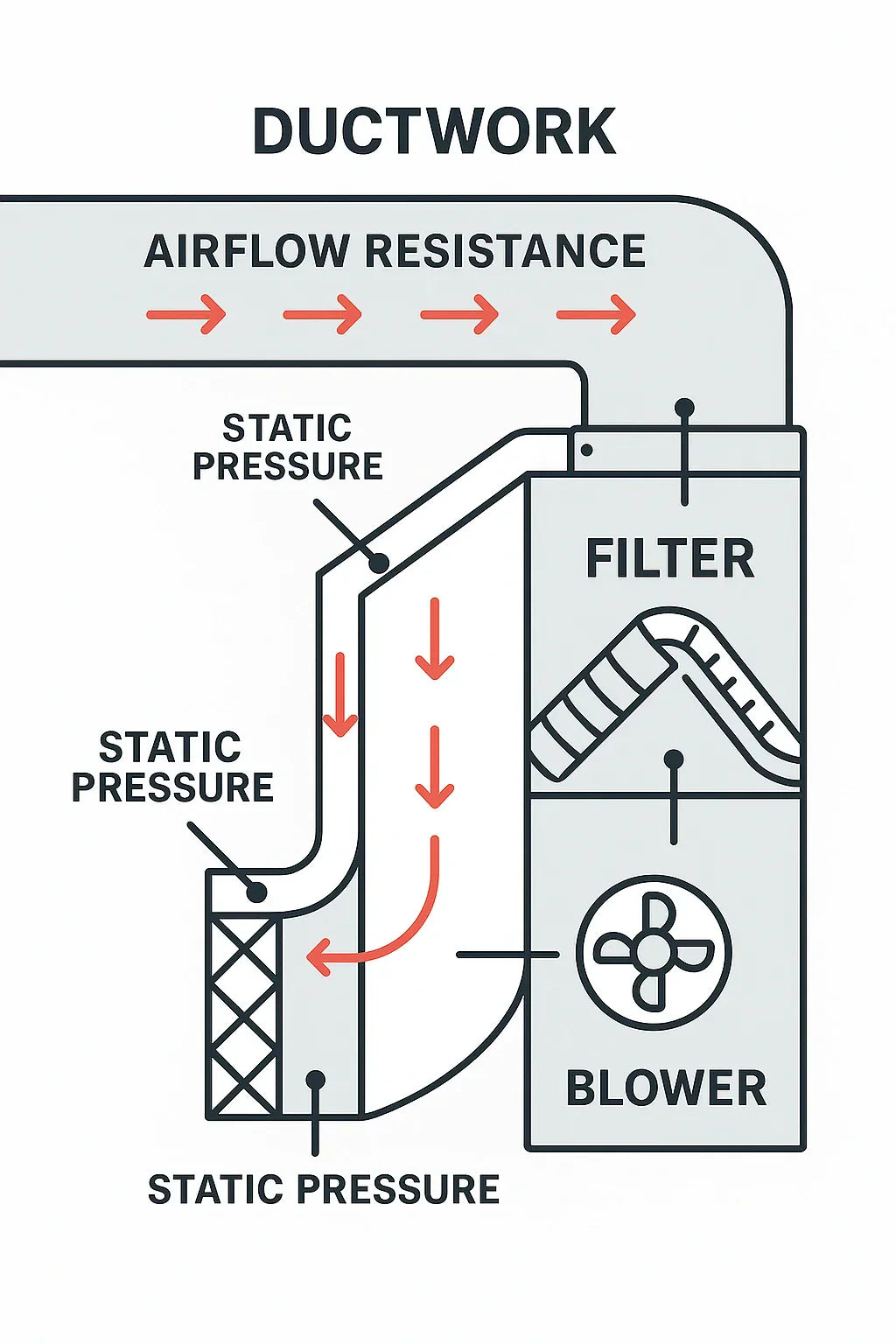

External static pressure is the resistance your HVAC system faces when pushing air through the ducts, registers, coils, and filters. Think of it like blood pressure for your HVAC system — too high, and everything starts working harder than it should.

ESP is measured in:

-

Inches of water column (in. w.c.)

-

Typical residential systems aim for 0.5" w.c. or less

-

SEER (the old test) used just 0.1" w.c. — basically lab conditions

In the real world, duct bends, dirty filters, and undersized returns can easily push static pressure beyond what your system was designed for — especially if it’s been retrofitted without proper duct updates.

📘 Learn more: NY Engineers – Static Pressure Calculation in HVAC Design

Why SEER2 Includes Static Pressure (Unlike SEER)

The older SEER testing method gave homeowners an idea of how efficient a unit could be — but under perfect, unrealistic conditions. It didn’t account for real-world airflow restrictions. That’s why SEER2 was introduced, using updated testing procedures that reflect how equipment actually performs in the field.

The big change?

-

SEER was tested at 0.1" static pressure

-

SEER2 uses 0.5" static pressure — much closer to what you see in typical homes

This makes the efficiency numbers more honest. Units now have to prove they can perform under realistic duct loads, not just in a lab.

📘 SEER2.com – About the New SEER2 Standard

How ESP Affects SEER2 Ratings

1. Efficiency Ratings Go Down With Higher Pressure

Even the most efficient unit will perform poorly if it’s starved for airflow. If your ducts can’t deliver enough air, the system uses more power to do less work.

2. Lower Airflow = Less Comfort

High static pressure can cause:

-

Inconsistent room temperatures

-

Weak airflow at vents

-

Noisy operation

-

Increased wear on blowers

3. Variable-Speed Units Are Sensitive to ESP

New high-SEER2 systems often come with variable-speed motors and compressors, which are great for efficiency — but only if airflow is dialed in. Excess pressure forces them to ramp up, reducing part-load efficiency (where SEER2 ratings assume they’ll run most of the time).

📘 Polar Bear Mechanical – What Causes High Static Pressure in HVAC

What Causes High Static Pressure in Homes?

You don’t need to be an HVAC tech to recognize the common culprits of poor airflow. Here’s what often pushes ESP above safe levels:

⚠️ Undersized or Poorly Designed Ductwork

Too small or too many bends = massive airflow restriction.

⚠️ Dirty Filters and Coils

Clogged filters or coils choke air movement. A common and easy fix.

⚠️ Closed or Blocked Vents

Closing vents can spike pressure in the rest of the system.

⚠️ Retrofitting Without Duct Changes

Upgrading your equipment without upgrading your ductwork is like putting a race engine in a go-kart.

📘 DOE Guide to Home Heating & Cooling (PDF)

What HVAC Contractors Need to Do Differently Under SEER2

SEER2 didn’t just raise the bar — it changed the install game. Contractors now need to evaluate duct performance, not just equipment specs.

✅ Test and Measure ESP

Installers should use a manometer to test actual static pressure before and after installation. If they don’t? That’s a red flag.

✅ Match Equipment to Ducts

A high-efficiency system is pointless if the ducts can’t keep up. Sizing must include Manual D ductwork calculations, not just Manual J load estimates.

✅ Educate Homeowners on Filter Maintenance

Even the best system will fail if filters aren’t changed regularly — especially high-MERV filters that restrict airflow faster.

📘 AAON – What Is Static Pressure and How It Affects HVAC Performance

Final Thoughts: Why Homeowners Should Care About ESP

SEER2 ratings are a big step forward — but they only work if your system is designed and installed with airflow in mind. A 17 SEER2 unit might test great in the lab, but if your ductwork is outdated or your static pressure is sky-high, it won’t live up to its rating in your home.

If you’re planning a new install or replacement, ask your contractor about static pressure testing, duct sizing, and filter options. It’s the difference between paper efficiency and real-world comfort and savings.

To learn more about why SEER2 matters and how it’s reshaping HVAC standards, check out the full breakdown:

🔗 What is SEER2 and Why It Matters

👉 Next in the Series: Are SEER2-Rated Systems Worth the Upgrade from SEER Units?

Alex Lane

Your Home Comfort Advocate