The HVAC industry is in the midst of a profound supply crisis. As highlighted in our previous post, Understanding the R-454B Refrigerant Shortage in 2025, a perfect storm of regulatory deadlines, global supply chain vulnerabilities, and heightened demand has led to widespread disruption. But as this shortage stretches on, new and concerning trends have begun to emerge—ranging from the rise of dangerous technician workarounds to the theft of HVAC units for their refrigerant.

This article takes a deeper dive into the 2025 R-454B refrigerant shortage, its real-world implications, and how professionals and homeowners can navigate the turmoil safely and legally.

What is R-454B and Why Is It So Critical?

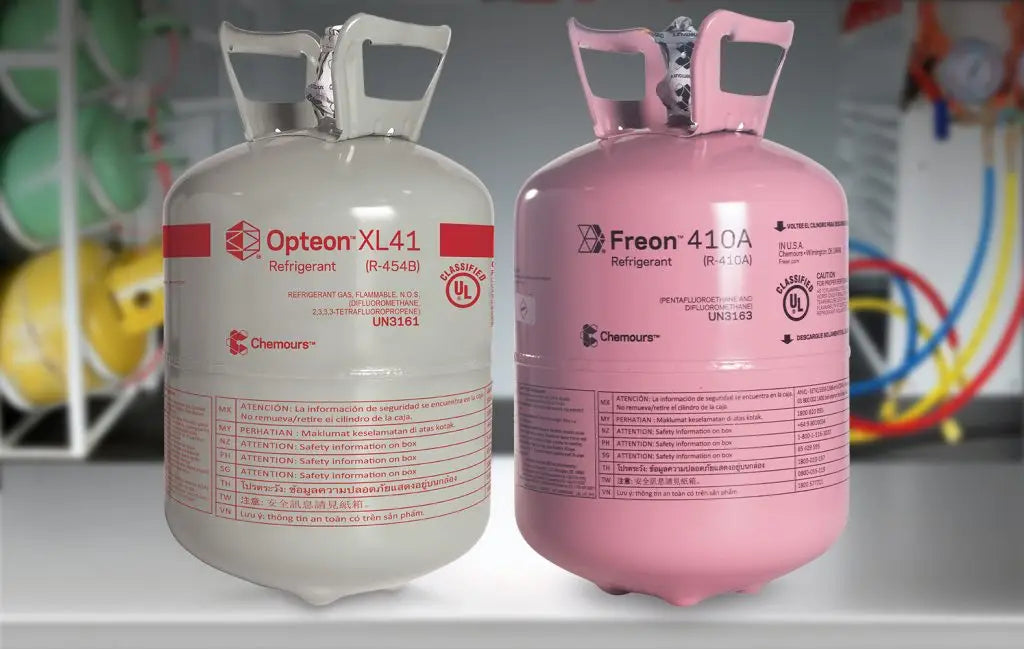

R-454B (marketed under trade names like Puron Advance and Opteon XL41) is a low-GWP (Global Warming Potential) refrigerant meant to replace the widely used R-410A. It is composed of 68.9% R-32 and 31.1% R-1234yf, resulting in a GWP of just 466—roughly 78% lower than R-410A’s GWP of 2088.

The urgency behind its adoption is largely regulatory. In line with the American Innovation and Manufacturing (AIM) Act, the U.S. Environmental Protection Agency (EPA) has mandated an aggressive phase-down of high-GWP hydrofluorocarbons (HFCs). As of January 1, 2025, HVAC manufacturers are prohibited from producing residential systems using R-410A.

The problem? This transition to R-454B hasn’t gone smoothly.

Root Causes of the R-454B Shortage

1. Regulatory Mandates Created a Bottleneck

The 2025 deadline has caused a sudden industry-wide rush toward R-454B-compatible systems. Many HVAC professionals have noted that the supply of equipment and refrigerant alike has been anything but smooth. According to a recent Spectrum News report, dealers across the country are facing weeks-long backorders, and contractors are scrambling to find the refrigerant needed to finish installations.

2. Cylinder Production Delays

The situation is further complicated by a shortage of A2L-certified cylinders, which are legally required for transporting and storing R-454B due to its mildly flammable nature. According to RSES industry news, manufacturers like Chemours and Worthington Enterprises are struggling to meet demand for these specialized containers, putting further pressure on distribution timelines.

3. Supply Chain Fragility and Hoarding

Some contractors and suppliers have responded to the uncertainty by hoarding inventory, further skewing availability. This kind of panic buying—common during supply disruptions—has only deepened the scarcity, making it harder for smaller or rural HVAC firms to get the products they need.

Real-World Consequences of the Shortage

1. Skyrocketing Prices

One of the most visible effects of the shortage is cost. As outlined in this detailed breakdown from Aristotle Air, 20-pound cylinders of R-454B that cost under $200 in 2021 are now fetching prices between $650 and $2,000, depending on location and supplier relationships. For HVAC installers already facing tight margins, this is a major blow.

2. Installation Delays and Project Cancellations

Because many new systems ship with only a partial R-454B factory charge, contractors are expected to top off refrigerant on-site. But with limited access to the gas, many installs are being delayed or even canceled altogether. Some distributors report waitlists stretching into the next season.

3. Unsafe Workarounds: Mixing Refrigerants

In the face of rising costs and delays, some technicians are turning to desperate and dangerous workarounds—like mixing refrigerants. This practice is not only illegal but can lead to compressor damage, voided warranties, and severe safety hazards. As outlined by ACHR News, the industry is strongly advised to avoid such practices at all costs.

Mixing R-454B with other refrigerants can alter system pressures unpredictably and result in system failure. Worse, it could create highly flammable or even explosive conditions in some environments. It’s simply not worth the risk.

4. Theft and Black Market Activity

The high price and scarcity of R-454B have fueled criminal activity, especially theft of HVAC units from homes and construction sites. In many cases, the goal isn’t to steal the equipment but to extract and resell the refrigerant inside.

This alarming trend is spreading, especially in urban areas with high demand. Builders are now being advised to secure outdoor units with heavy-duty cages, locks, and even GPS tracking in high-theft areas.

Legal and Safe Strategies for Navigating the Crisis

1. Communicate with Customers Proactively

Transparency goes a long way. Explain the situation to your clients—let them know the shortages are national in scope and that you’re working diligently to secure product. Make sure to inform them about the dangers of unlicensed installers or refrigerant substitutes.

2. Plan Projects Around Known Supply Schedules

When possible, plan installation schedules based on confirmed refrigerant availability. Consider batching similar system installs or consolidating purchase orders with trusted suppliers to maximize consistency.

3. Consider Safe Alternatives (With Caution)

While R-32 has been floated as a possible workaround due to its higher availability and low GWP (675), it’s not a plug-and-play substitute. As explained in our article on why R-32 may be your lifeline, using R-32 requires dedicated equipment. It should only be used in systems designed specifically for it.

Never retrofit or “hack” existing R-454B systems for use with other gases.

4. Invest in A2L Training and Equipment

Technicians need proper certification and training for handling mildly flammable refrigerants like R-454B. The Heating, Air-conditioning & Refrigeration Distributors International (HARDI) organization offers safety resources, webinars, and training guidelines that can help businesses stay compliant.

Voices from the Industry: Expert Perspective

In Tony Marino’s recent article, he emphasized that the real challenge isn’t the shortage itself—it’s how companies and technicians respond to it. According to Marino, “The worst thing you can do right now is compromise safety or compliance just to make a fast buck.”

He encourages companies to:

-

Stock strategically, not reactively

-

Invest in safety training

-

Build strong supplier relationships

-

Educate customers, especially about why cutting corners is dangerous

The Global Context and What's Next

The R-454B shortage isn't an isolated incident—it’s part of a broader global refrigerant transition. In the EU, Canada, and other countries, similar phase-outs are underway. Even Japan and Australia are beginning their shift toward A2L-class refrigerants.

According to a report from the Cooling Post, leading U.S. manufacturers are lobbying for expedited imports and expanded cylinder production to ease the pressure. Still, experts warn that it may take several quarters before supply stabilizes.

Key Takeaways

| Topic | Summary |

|---|---|

| What is R-454B? | A low-GWP refrigerant replacing R-410A. |

| Why is there a shortage? | Regulatory deadlines, A2L cylinder shortages, and hoarding. |

| What are the risks? | Mixing refrigerants, system failure, thefts, and black-market sales. |

| Legal strategies | Transparency, planned scheduling, safe alternatives, training. |

| Industry insight | Tony Marino calls for ethics, safety, and long-term thinking. |

Conclusion: Staying Smart and Safe Amidst the Crisis

The R-454B shortage of 2025 is more than just a supply hiccup—it’s a test of the HVAC industry’s integrity, safety standards, and adaptability. As tempting as shortcuts may be, they can cause irreversible damage, legal trouble, and even physical danger.

By embracing strategic planning, customer education, and compliance with regulations, HVAC professionals can weather this storm and emerge stronger on the other side.

For more insights and updates on how to navigate the 2025 HVAC refrigerant shortage, follow our ongoing coverage and expert tips at The Furnace Outlet HVAC Blog.

Further Reading & Authoritative Sources: