When most people think about HVAC sizing, their focus is on the furnace, air conditioner, or heat pump. But here’s a detail that often gets overlooked: ductwork sizing can make or break your system’s performance.

Your ducts are the pathways that deliver conditioned air throughout your home. If they’re the wrong size, even the most efficient unit will waste energy, wear out faster, and leave you uncomfortable.

Ducts are the “silent partner” in HVAC design. You don’t see them every day, but they have a direct impact on efficiency, comfort, and cost.

If you need the fundamentals on HVAC equipment sizing, start here: How to Size an HVAC System for Your Home. Once you understand that, this article will show you why ductwork sizing deserves equal attention.

Why Ductwork Sizing Matters

Think of ducts as the “lungs” of your HVAC system. They move air in and out—supply ducts deliver conditioned air, return ducts bring it back. If they aren’t sized correctly, airflow suffers.

The U.S. Department of Energy reports that poorly designed or installed ducts can waste 20–30% of the air moving through them. That means higher bills, more wear on your HVAC system, and uneven comfort throughout the home.

Bad duct design doesn’t just affect efficiency—it also impacts comfort. Too-small ducts restrict airflow, too-large ducts reduce velocity, and both result in uneven heating and cooling.

Signs of Poorly Sized Ductwork

You don’t need to be an HVAC pro to spot duct sizing issues. Here are common warning signs:

Uneven Temperatures

One bedroom feels like a freezer while another is always stuffy. That’s a red flag that ducts aren’t balanced for proper airflow.

High Energy Bills After a New Install

If you’ve upgraded to high-efficiency equipment but bills haven’t dropped, ductwork may be to blame. According to a continuing education resource from CED Engineering, duct efficiency depends on three things: correct sizing, airtight sealing, and proper insulation. Skip any one of these, and you undermine system performance no matter how efficient your furnace or AC may be.

Noisy Vents

Whistling, banging, or “whooshing” sounds mean air is struggling to move through undersized ducts.

Short Cycling or Strain on Equipment

When airflow is restricted, the system overheats or ices up, forcing it to shut down early. The ASHRAE airflow standards confirm that improper duct sizing contributes to premature wear and short cycling.

The Science Behind Ductwork Sizing

Static Pressure: HVAC’s Blood Pressure

Airflow through ducts is measured in static pressure. Just like blood pressure, it must stay in a healthy range:

-

Too high: Ducts are too small; air can’t move freely.

-

Too low: Ducts are too big; air loses momentum.

-

Balanced: The blower motor works efficiently, delivering even airflow across the home.

Manual D Calculations

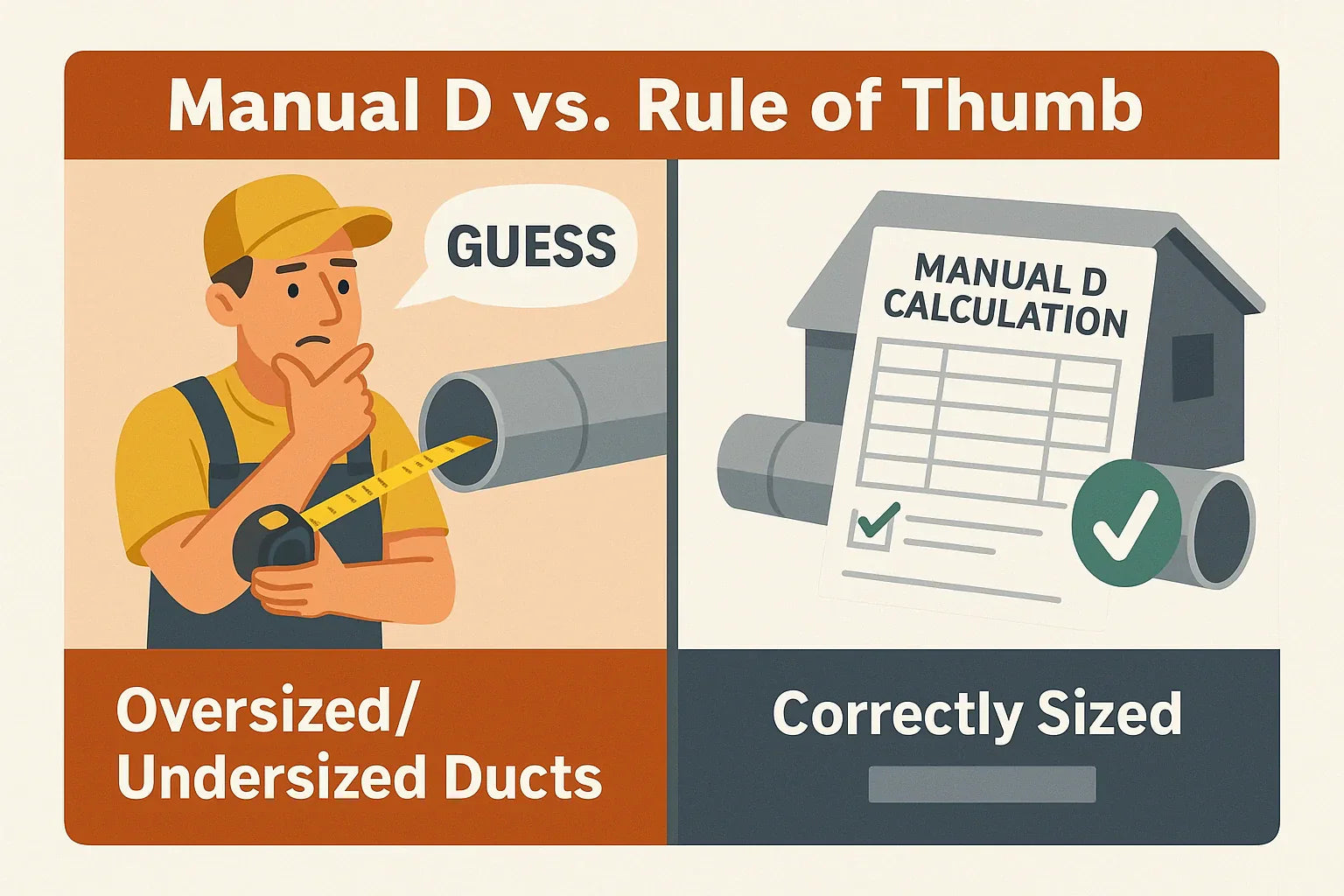

Sizing ducts isn’t guesswork—it’s math. Just as Manual J is the standard for equipment sizing, Manual D is the standard for duct design.

The Air Conditioning Contractors of America (ACCA) created Manual D to calculate duct size based on:

-

Home’s room-by-room load (from Manual J).

-

Duct material and layout.

-

Friction loss and airflow velocity.

Without Manual D, contractors often oversimplify and use “rule of thumb” sizing. That shortcut can cost homeowners thousands over time.

Return Ducts: The Forgotten Half

Most homeowners focus on supply ducts, but return ducts are equally critical. Without proper returns, your system can’t “breathe.”

The EPA notes that insufficient return airflow can harm indoor air quality, increase dust, and reduce overall ventilation.

Common Mistakes Contractors Make

Unfortunately, ductwork is often where corners get cut. Here are mistakes I see most often:

-

Rule of Thumb Design: Using square footage instead of Manual D.

-

Undersized Ducts: Installed to save space, but cause high static pressure and noisy airflow.

-

Ignoring Sealing and Insulation: Even correctly sized ducts leak air if unsealed.

The ENERGY STAR duct sealing guide estimates that sealing and insulating ducts can boost efficiency by up to 20%. Yet many installations skip this step.

Best Practices for Homeowners

So, how can you make sure your ducts are sized right?

Demand Manual J and Manual D

Your contractor should calculate both equipment load and duct size. Anything less is guesswork.

Seal and Insulate Ducts First

Leaky ducts waste conditioned air. Always address sealing and insulation before upgrading equipment.

Request Airflow Testing

A static pressure test reveals whether your ducts are operating in the correct range.

Work With HVAC Professionals

Not all contractors follow proper duct design standards. Ask if they’ve been trained in Manual D calculations.

For the next step in HVAC right-sizing, read: Do You Need Different HVAC Sizes for Heating vs. Cooling?

Final Thoughts

Ductwork may be hidden behind walls and ceilings, but its role is front and center in your comfort and your utility bills. Undersized, oversized, or leaky ducts can undermine even the best HVAC equipment.

By insisting on Manual D calculations, sealing and insulating ducts, and testing airflow, you’ll protect your investment and enjoy the comfort you paid for.

Remember: a great HVAC system is only as good as the ductwork that supports it.

Alex Lane

Your Home Comfort Advocate