High-efficiency furnaces are designed to deliver consistent warmth while operating much more quietly than their older, single-stage predecessors. But “quiet” doesn’t mean completely silent—and not all noises are cause for alarm. Understanding what’s normal, and what isn’t, can help you protect both your comfort and your investment.

In this guide, I’ll break down the sounds you should expect from a high-efficiency furnace, the noises that signal trouble, and when it’s time to call a professional.

📘 Related reading: High-Efficiency Furnaces: Worth the Investment?

Why Furnace Noise Matters

Noise is more than just a comfort issue. Unusual furnace sounds can reveal hidden problems that impact:

-

Safety: Certain noises, like bangs from delayed ignition, may point to combustion issues.

-

Efficiency: Noisy systems often work harder than they should, reducing their AFUE rating.

-

Cost: Ignoring early warning sounds may lead to bigger, more expensive repairs.

According to the U.S. Department of Energy (DOE), furnaces must meet strict efficiency and safety standards. Monitoring how your furnace sounds is one simple way to make sure it’s meeting those standards in your own home.

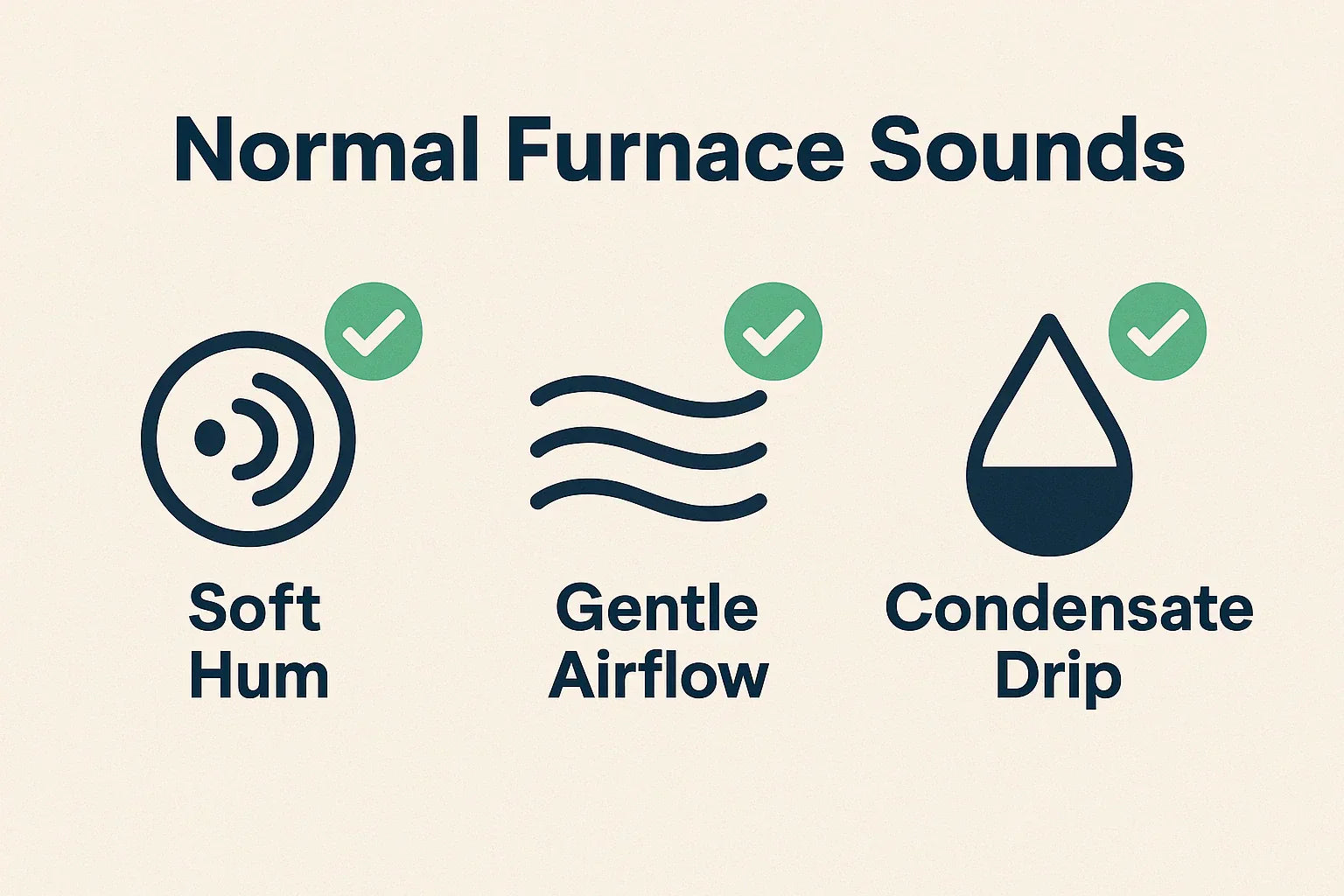

What Normal Furnace Sounds Should You Expect?

Even the quietest high-efficiency furnace will make some noise during operation. The key is knowing which ones are normal background sounds and which are warning signals.

Startup and Shutdown Noises

-

A soft click when the burners ignite.

-

A gentle whoosh or hum when the blower fan starts pushing air.

-

A faint click again when the furnace cycles off.

Blower and Fan Operation

-

Variable-speed blowers in high-efficiency models produce a steady, even hum.

-

The sound level may increase slightly on very cold days when the furnace ramps up airflow, but it should not be jarring.

Condensate Draining

-

Condensing furnaces create water as a byproduct of high-efficiency combustion.

-

It’s normal to hear a drip or light gurgling sound from the drain line.

The ENERGY STAR program notes that high-efficiency systems are engineered to run more quietly than standard furnaces. So, if your system produces only these low-level sounds, you can relax—it’s likely running just as it should.

Noises That Indicate a Problem

While some noises are harmless, others mean your furnace needs attention.

Banging or Popping

-

Cause: Ductwork expanding/contracting, or worse, delayed ignition of gas in the burner.

-

Risk: If caused by ignition issues, this can be dangerous and should be addressed quickly.

Whistling

-

Cause: Airflow restrictions—most often dirty filters, blocked vents, or undersized ductwork.

-

Fix: Replace the filter or check for blocked registers. Persistent whistling may require professional duct inspection.

Grinding or Screeching

-

Cause: Worn blower motor bearings or slipping belts.

-

Risk: Ignoring this noise could lead to blower failure.

Rattling or Vibrating

-

Cause: Loose furnace panels, unsecured ductwork, or failing components inside the cabinet.

-

Fix: Tighten screws or panels; if rattling continues, have a technician inspect the system.

Noise issues are covered in depth by organizations like ASHRAE, which sets standards for acceptable HVAC sound levels in residential buildings. Abnormal sounds aren’t just annoying—they often signal that your system is losing efficiency or approaching failure.

The EPA also stresses that properly maintained HVAC systems are essential to indoor air quality and safety. Unusual noises often go hand-in-hand with airflow and combustion issues that affect both.

DIY Checks Before Calling a Pro

Not every furnace noise requires immediate service. A few simple checks may save you a service call:

1. Inspect and Replace Filters

Dirty filters are one of the most common culprits for whistling or rushing air noises. Replace filters every 1–3 months, depending on your household.

2. Tighten Panels and Screws

Loose access panels or duct joints can create rattling or vibrating sounds. Make sure they’re securely fastened.

3. Clear Air Registers and Ducts

Blocked registers can increase pressure inside your ductwork, leading to whistling or banging sounds. Keep them clear of furniture or rugs.

4. Check Drain Lines

If gurgling sounds are louder than usual, inspect condensate drain lines for clogs.

The EIA offers insights into how small maintenance tasks can reduce household energy waste—filter checks and airflow fixes are among the simplest and most effective.

When to Call a Professional

Some noises are beyond the scope of DIY fixes and require expert help. Call a licensed HVAC technician if you notice:

-

Loud bangs or booms from delayed ignition.

-

Persistent grinding or screeching from blower components.

-

Rattling inside the cabinet even after tightening panels.

-

Sudden changes in sound after years of quiet operation.

The HVAC.com guide to furnace maintenance recommends annual professional service to inspect combustion, airflow, and mechanical components. Preventive maintenance visits often catch noise issues before they escalate into costly breakdowns.

Final Thoughts

A high-efficiency furnace should be quiet, but not silent. Gentle clicks, hums, and light airflow sounds are all normal. But loud bangs, whistles, screeches, or rattles are not.

The sooner you recognize the difference between normal and abnormal sounds, the sooner you can protect your furnace, your comfort, and your wallet.

📘 Learn more: Can You Install a High-Efficiency Furnace in a Mobile or Modular Home?

Alex Lane

Your Home Comfort Advocate