By Alex Lane | Your Home Comfort Advocate

Thinking about installing a heat pump yourself? You’re not alone. With mini-split systems becoming more efficient, affordable, and user-friendly, many homeowners are rolling up their sleeves and taking the DIY route — saving thousands in the process.

But before you dive in, let’s be clear: heat pump installation isn’t your average weekend project. It takes planning, tools, patience, and a healthy respect for building codes and refrigerant safety. This guide walks you through the essentials, step by step.

✅ Want to skip ahead and find the right mini-split system for your home? Check out our collection of R-32 ductless heat pump systems at The Furnace Outlet.

Why Go DIY With Heat Pump Installation?

💰 The cost savings

Professional mini-split installs can run $3,000–$7,000 or more. A confident DIYer can install the same system for under $2,000, including tools and permits.

⚒️ The flexibility

Install on your own schedule. Customize line set routing and unit placement. Plus, you’ll gain an intimate understanding of how your system works — which helps down the line with maintenance.

⚠️ The caveats

If done incorrectly, a DIY install can void warranties, break local codes, or lead to performance issues. That’s why step one is always: know what you’re allowed to do.

Step-by-Step: How to Install a Mini-Split Heat Pump Yourself

1. Planning, Sizing, and Permits

Start by verifying whether your municipality allows homeowner-installed HVAC systems. Many areas require a permit — especially if you're connecting to high-voltage electrical or working with refrigerant.

Next, size your unit appropriately. Oversized systems short cycle and waste energy; undersized ones will run nonstop.

📘 Check if you need a permit via BuildingAdvisor

📘 Use ASHRAE’s residential sizing guidelines for accurate load calculations

📘 Learn more from Energy.gov’s heat pump guide

2. Choosing the Right System

Look for a high-efficiency mini-split with a SEER2 rating of at least 18 and HSPF2 above 9. Top-rated systems are pre-charged and designed for DIYers. Stick with models that come with line sets, communication cables, and wall sleeves included.

📘 Check if your unit is listed in the AHRI Certified Directory to ensure it meets DOE performance standards.

3. Gathering Your Tools and Materials

This isn’t a casual screwdriver-and-hammer kind of job. DIY mini-split installation requires precision tools, especially for handling refrigerant lines and electrical connections. Here’s what you’ll need — and why it matters:

🛠️ Essential Tools

-

Vacuum pump – Removes air and moisture from the refrigerant lines before opening the valves. Moisture can create acids inside the system.

-

Manifold gauge set – Measures pressure during evacuation and confirms proper vacuum levels. Must be R-32 compatible.

-

Digital micron gauge – Precisely verifies that you've reached a vacuum below 500 microns.

-

Torque wrench – Ensures flare nuts are tightened to spec — not too loose, not over-crushed.

-

Flaring tool – For field-flared connections, especially when customizing line lengths.

-

Tubing bender – Prevents kinks in copper refrigerant lines.

-

Hole saw (2.5”–3”) – To drill through the wall for the line set and wiring.

-

Level and tape measure – For mounting brackets and checking slope on the drain.

-

Cordless drill & concrete anchors – Securing outdoor pad or bracket.

🧰 Optional But Recommended

-

Line set cover kit – Protects copper lines from UV damage, gives a clean look.

-

Nitrogen tank & regulator – For pressure testing (more advanced).

-

Fin comb & coil cleaner – For future maintenance.

📝 Pro tip: Invest in quality tools or rent from an HVAC supply shop. Don’t skimp on gauges or torque wrenches.

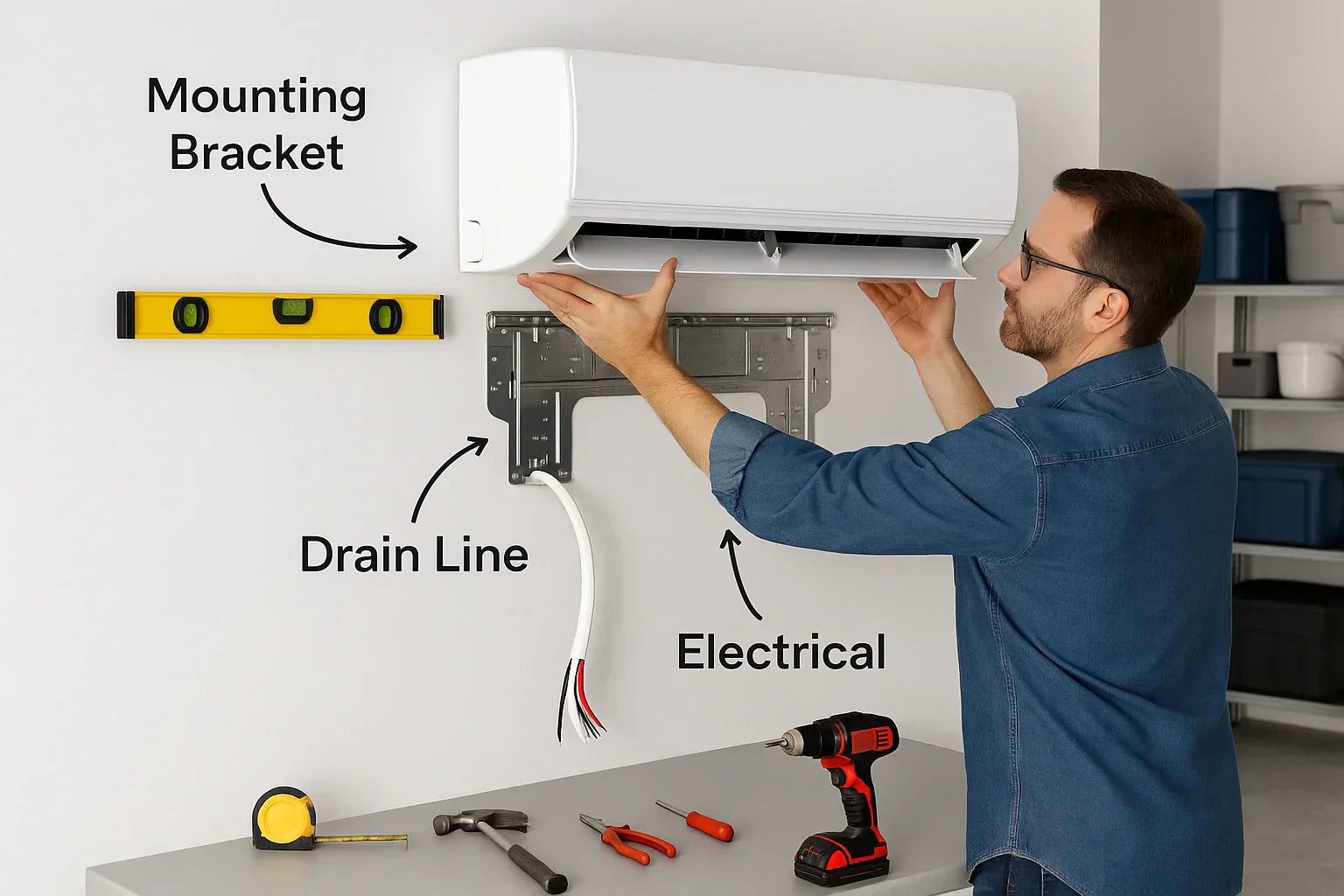

4. Installing the Indoor Unit

Mount the bracket on an exterior-facing wall, ideally 6–7 feet off the floor, and away from heat sources or furniture. Use a level to get it straight — especially important for proper drainage.

Drill a 2.5–3” hole at a slight downward angle to run the line set, drain hose, and control wire outside. Feed everything through and secure the indoor head unit onto the bracket.

Seal the hole with outdoor-rated caulk or putty to prevent moisture and pests.

5. Setting the Outdoor Unit

Your condenser should sit on a concrete pad, plastic base, or wall bracket. It needs at least 12” of clearance from walls and 24” of open space in front of the fan. If you’re in a snowy climate, raise it above the snow line.

Install the high-voltage disconnect box nearby and follow the manufacturer’s electrical diagram for wiring.

📘 Reference National Electrical Code (NEC) for HVAC circuits and local compliance.

6. Running the Line Set and Electrical

Route your copper line set from indoor to outdoor carefully. Avoid tight bends or pinches. Use insulation wrap or pre-insulated lines and secure them in a line set cover.

Connect control wiring from the indoor unit to the outdoor terminal block as specified. Double-check polarity and follow wire color coding exactly.

7. Evacuating and Testing

This is where many DIYers get tripped up — but it’s the most critical part.

💨 What is evacuation?

Evacuation removes air, nitrogen, and especially moisture from the refrigerant lines. Moisture can cause corrosion and reduce system efficiency.

✅ Step-by-Step:

-

Connect manifold gauges and vacuum pump

Blue hose to service port, yellow to the pump. Add a digital micron gauge if available. -

Start vacuum and pull down to 500 microns

Let the pump run for 30–90 minutes depending on conditions. -

Close valves and do a decay test

Let the system sit sealed for 15 minutes. If pressure stays under 1000 microns, you're good. If it rises fast, there’s a leak or moisture. -

Do a soap bubble leak test

Apply solution to flare joints. Look for bubbling. -

Release refrigerant

Open the service valves using an Allen wrench. The pre-charged refrigerant will fill the system.

📘 More details: ESCO Institute’s Mini-Split Best Practices

🧊 Important: DIY systems are usually pre-charged for 15–25 ft line sets. If you extended your lines, you may need a licensed tech to top off refrigerant.

What Can a DIYer Legally Do?

You can mount units, run wiring (in most states), and connect the control lines. But in some regions, handling refrigerant without EPA certification is prohibited — even if the system is pre-charged.

Some homeowners hire a licensed HVAC tech for a one-time “startup” service: they’ll handle evacuation, final connections, and testing.

Common Mistakes That Can Cost You

-

Bad flares – Leaky joints from under- or over-torqued connections.

-

Kinked lines – Restrict refrigerant flow, reduce performance.

-

No vacuum – Leads to moisture in the system. Never skip this step.

-

Flat drain slope – Water backs up and leaks inside.

-

No permit or inspection – Can cause insurance or code issues later.

Post-Install: Testing and Long-Term Care

After opening the valves and powering on the system:

-

Test all modes: heat, cool, fan, and dry.

-

Listen for abnormal noises or vibration.

-

Register your warranty and record serial numbers.

-

Clean filters every month. Rinse coils twice a year.

-

Keep the outdoor unit clear of leaves, dust, or snow.

-

Book a pro for annual servicing — yes, even for DIY systems.

Final Thoughts from Alex Lane

Installing your own heat pump isn’t for everyone. But if you’ve got the patience, a bit of electrical know-how, and the right tools, it’s absolutely doable.

Plan ahead. Read the manual — twice. Know your limits. And don’t hesitate to bring in a pro for the tricky parts.

Alex Lane

Your Home Comfort Advocate