Key takeaways (at a glance)

-

Install time: 1–3 days with pro install (depends on ducts/electrical).

-

Costs (2025): $3,300–$7,800 typical; full system $11,590–$14,100.

-

Quote: Send photos for estimate.

-

Financing: Payment plans available.

-

Sizing: ~1 ton per 500–600 sq ft (confirm with Manual J).

Why central air installation matters right now (2025)

Hotter summers and longer heat waves mean more U.S. homes are moving to full central air. The challenge isn’t just buying equipment—it’s understanding the installation process and cost breakdown so you can plan without surprises. A typical professional install takes 1–3 days, and the decisions you make before day one (sizing, duct condition, efficiency rating, refrigerant type) drive comfort and lifetime cost. In 2025, two trends matter most: SEER2 (the newer efficiency test standard) and the industry shift to R-32 refrigerant. Both affect upfront price and power bills over the next decade. This guide explains each step in plain language, shows where dollars go, and calls out expert tips you can use to avoid rework. If you want quick ballpark numbers, check our takeaways above; if you want confidence from start to finish, read on and bookmark the resources linked throughout.

The common problem: unclear pricing, confusing jargon, and bad timing

Many homeowners hit the same snags: estimates that don’t match the final invoice, tech terms like SEER2, Manual J, and line set that sound abstract, and scheduling installs during summer’s rush when prices and wait times jump. Here’s the core issue: every home is different, and skipping the early homework (load calculations, duct checks, and electrical review) causes oversizing, short cycling, and higher bills. Another pitfall is ignoring permit timelines or utility rebates until the last minute. You can control what you understand and when you schedule. Read through the sections on sizing, costs, and timing below, and use our Sizing Guide and HVAC Financing pages to plan before peak season. When you know the vocabulary and sequence, your quotes get clearer and your system performs as promised.

Step-by-step overview: from assessment to first cool air

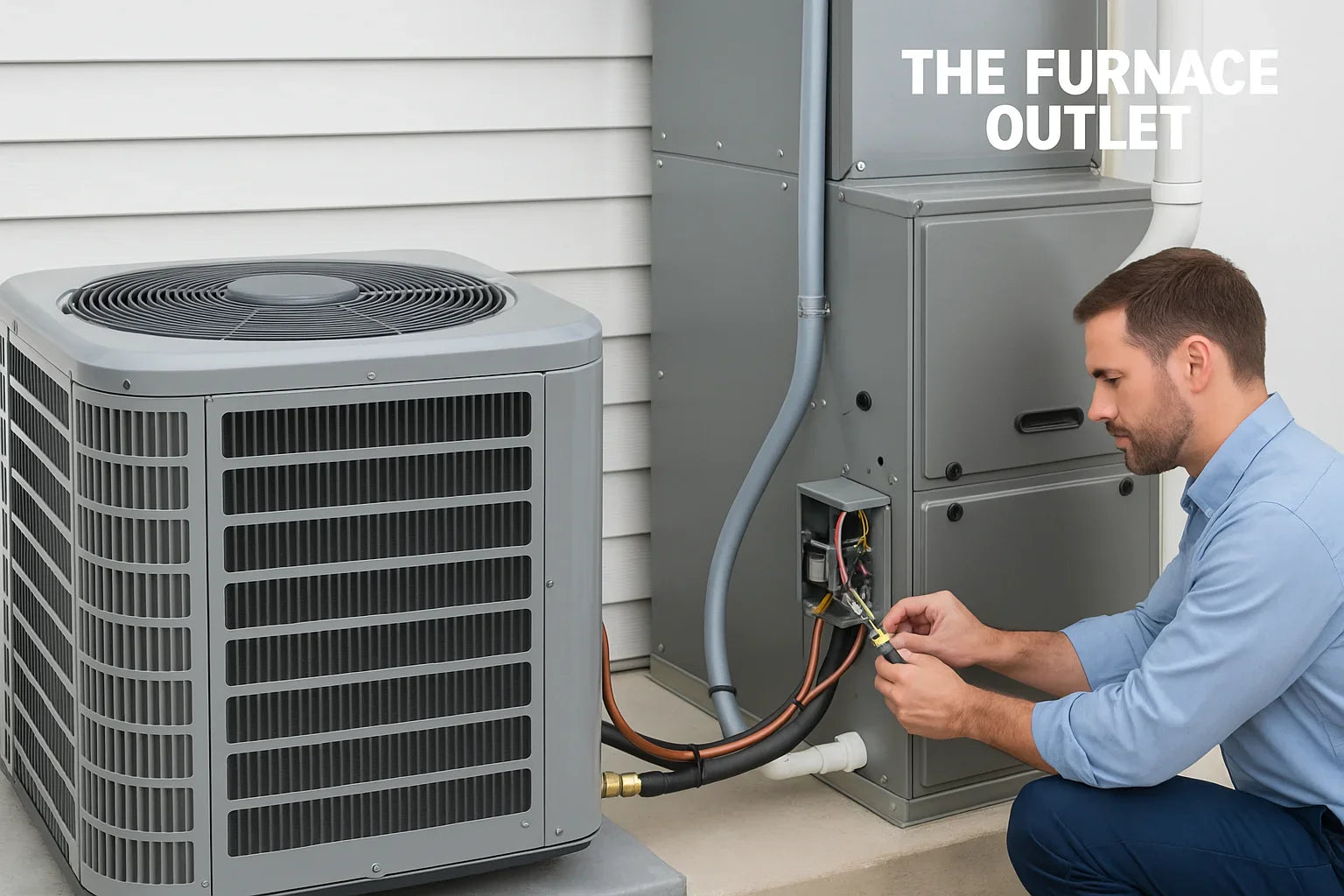

Think of installation in four clean phases: pre-installation, removal & prep, install, and testing. First, a licensed pro performs a Manual J to size the system and checks duct leakage, insulation levels, and airflow targets. Second, if replacing equipment, the team safely recovers old refrigerant (EPA-required), removes the air handler/furnace coil, and protects floors and walls. Third, they set the outdoor condenser on a level pad with clear airflow (6–10 inches from walls), mount the evaporator coil above the furnace or in the plenum, run copper refrigerant lines through a sealed wall penetration, and complete electrical work (often a 30-amp breaker and dedicated disconnect). Finally, they charge, test, and calibrate: refrigerant levels, static pressure, supply/return temps, and thermostat programming. Use our Quote by Photo tool to streamline that first assessment and reduce back-and-forth.

Sizing your system: Manual J, tons, and ductwork checks

Proper sizing is the most important decision you’ll make. While a quick rule says 1 ton per 500–600 sq ft, only a Manual J accounts for your home’s actual heat gain—window area, orientation, insulation, air leakage, occupancy, and climate. Oversized systems short-cycle and leave humidity high; undersized systems run constantly and still miss setpoint. Ask your installer to show the load results and the chosen CFM per ton target for your ducts. If ducts are leaky or undersized, fix them now; sealing with mastic and balancing airflow can boost effective efficiency by 20–30%. If you’re planning a coil or air handler swap, compare matched components in our R-32 AC & Air Handler Systems and Air Handlers collections. Good design beats raw tonnage every time and prevents noisy returns, hot rooms, and early compressor wear.

What pros do on install day: outside, inside, lines, and power

Here’s the short version of a clean, code-compliant install. Outdoors, the condenser goes on a stable, level pad with proper clearances, anchored per local code, and connected to a weather-rated disconnect. Indoors, the evaporator coil is set above the furnace or inside the air handler, with a new condensate drain and trap, and careful sealing where the coil cabinet meets the plenum. Refrigerant lines are sized correctly, brazed with nitrogen purge to protect tubing, pressure-tested, evacuated to deep vacuum, then charged to specs. Electrical work includes dedicated circuits, breaker sizing, and bonding/grounding. The thermostat is verified (or upgraded to a smart model). If your current line set is damaged or the wrong size, plan on a replacement—browse Line Sets and related Accessories to budget correctly. Small details here—vacuum levels, torque on service valves—decide long-term reliability.

Testing & quality assurance: what “done right” really looks like

Before anyone leaves, insist on documented startup and commissioning. A pro will: (1) confirm refrigerant charge by superheat/subcooling, (2) measure static pressure and compare to blower tables, (3) verify CFM delivery to key rooms, (4) check electrical draw against nameplate, and (5) calibrate your thermostat. Expect a quick duct leakage discussion and photos of connections. Ask for the model/serial numbers of matched indoor/outdoor components and the final charge amount in ounces. If you’re using a smart thermostat, enable circulation and humidity control features as available. Commissioning protects your warranty and ensures the system meets its SEER2 performance potential.

Cost breakdown you can trust: equipment, labor, and extras

Here’s how costs usually stack up. Equipment is driven by size (tons) and efficiency: 2–3 ton systems often land around $1,900–$5,500 for equipment; 3–4 ton at $2,600–$7,000; 4–5 ton at $3,500–$8,500. Labor for a professional install frequently runs $1,500–$3,500 for 1–3 days of work, permits, setup, and commissioning.

Add-ons to expect: ductwork ($3,000–$5,000+ if new), electrical upgrades ($200–$800), permits/inspections ($250–$400), and a pre-install evaluation ($300–$900). In 2025, many homeowners see totals between $3,300 and $7,800 for straightforward replacements; full system replacements can reach $11,590–$14,100. For current market snapshots and examples, see our 2025 blog breakdown.

Smart timing, financing, and payback: make the numbers work

Seasonality matters. Late fall or early spring often means better availability and calmer pricing than peak summer. If you’re comparing efficiency tiers, remember: a 16 SEER-equivalent system can cut energy use by roughly a fifth or more versus older models, so higher upfront cost may pay back through lower bills. Look for rebates, utility incentives, and manufacturer promos.

If spreading payments helps, compare fixed-rate personal loans, home-equity options, or manufacturer promos on our HVAC Financing page. Planning R-32 equipment? Browse R-32 Condensers and R-32 Complete Systems to see what fits your load and budget. For a quick primer on why efficiency test changes matter to buyers, this guide helps tie costs to real-world savings

Maintenance & performance tips: keep bills low for years

Plan pro maintenance twice a year (spring and fall) and keep a short DIY checklist. Replace filters monthly in peak season, keep the outdoor coil clear of leaves and grass, and verify supply vents aren’t blocked by furniture. Use a programmable or smart thermostat with schedules that match your home. Avoid setting indoor temps more than 20°F below outdoor temps; this reduces strain and shortens run times.

If you upgraded equipment but kept ducts, schedule a duct cleaning/sealing to protect your investment and improve indoor air quality. When parts wear or you add runs, shop Accessories and Line Sets as needed. If you’re new to duct design basics, this refresher from our blog explains airflow, layout, and sizing choices that lower static pressure and even out room temps.

Frequently asked questions

How long does central air installation take?

Most installs finish in 1–3 days. Add time if you’re adding new ductwork or electrical service.

What size AC do I need?

A quick estimate is 1 ton per 500–600 sq ft, but ask for a Manual J to be accurate for your home.

Do I need new ducts?

If ducts are leaky, undersized, or dirty, you’ll lose comfort and efficiency. A pro test tells you whether to seal, resize, or replace.

What raises the price the most?

New ductwork, high-efficiency equipment, electrical upgrades, and permits. Seasonal demand also affects labor rates.

Is R-32 worth it?

R-32 is common in 2025 and pairs well with modern, efficient systems. It can lower energy use when matched and installed correctly; check local code and pro guidance.

Should I replace the line set?

If it’s the wrong size, damaged, or contaminated, yes. Proper line sizing and a clean vacuum are key to reliability.

Can I DIY central air?

Full DIY is not recommended due to refrigerant handling, electrical work, and code requirements. Use licensed, insured pros; you can prep by clearing work areas.

When should I schedule the project?

Try late fall or early spring to avoid peak pricing and limited availability.

Where can I learn more from your team?

Start at the HVAC Tips and use the Sizing Guide and HVAC Financing pages to plan your project