Key Takeaways (Quick Reference)

-

Proper sizing: Manual J prevents hot/cold spots.

-

Airflow: Manual D keeps rooms balanced.

-

Refrigerant: Deep vacuum protects compressor.

-

Timeline: Same day or 1–3 days with ducts.

-

Cost: Efficiency, ducts, and upgrades impact price.

How the Central Air Installation Process Works

If you’ve ever wondered why two homes with the same square footage feel different after a new AC, the answer is the installation process. Installing central air is more than dropping in a condenser. It’s a step-by-step build that balances heat load, airflow, electricity, and drainage so your home stays even and quiet. Today’s trend toward higher-efficiency R-32 equipment makes the process even more precise. In this guide, you’ll learn how pros size your system, design ducts, run line sets, evacuate refrigerant lines, and commission everything so it runs right from day one.

Problem Statement: Common Concerns and Why They Matter

The biggest worries homeowners share are wrong system size, poor airflow, refrigerant leaks, and surprise costs. These issues matter because they show up as rooms that never cool, noisy vents, short cycling, high utility bills, and early part failures. Most problems start before the first screw is turned—during sizing and design. Without a Manual J calculation, contractors often oversize equipment “just in case,” which leads to humidity problems and uneven temperatures. Skipping Manual D duct design can starve rooms of airflow. Rushed refrigerant work (no deep vacuum or decay test) traps moisture that eats components from the inside. The fix is a clear, phase-by-phase plan and quality checks at every step. Use our Help Center for prep tips, and consider a quick photo quote via Quote by Photo to spot issues early.

Phase 1: Site Evaluation & Manual J Load Calculation

Everything begins with a home assessment and a room-by-room Manual J. Techs measure square footage and ceiling height, check insulation levels, window area and sun exposure, number of occupants, and heat from appliances. They also factor infiltration (how much outside air slips in), ventilation needs, local design temperatures, and even altitude for accuracy. The goal is to land on the right BTU target so you don’t over- or under-size. Expect pros to look at existing ductwork—its condition, accessibility, and leakage. A tight, well-insulated home might need less capacity than you think, while a leaky, sun-baked room might need more supply air. Ask for the printed Manual J report; it’s your blueprint for correct equipment size (usually 1.5–5 tons for most homes). To learn the basics in advance, skim our Sizing Guide and related posts in HVAC Tips.

Phase 2: Equipment Sizing, Matching & Manual D Duct Design

With load numbers in hand, the contractor selects a system with the right sensible (temperature) and latent (moisture) capacity. Indoor and outdoor components must be properly matched so the efficiency rating you pay for is the efficiency you actually get. Next comes Manual D: calculating CFM (airflow) per room, duct sizes, friction rates, and static pressure so air moves quietly and evenly. Good design also sets return locations and grille/register placement to avoid drafts. If you’re comparing equipment, explore R-32 condensers, air handlers

Phase 3: Pre-Installation Prep, Permits & Scheduling

Before tools come out, good teams set the table. Homeowner prep: clear paths to the attic/basement, move cars from the driveway, and keep pets safe. Put fragile items away. Contractor prep: pull required installation and electrical permits, verify deliveries, coordinate any utility work, and schedule inspections. If ducts need changes, materials are staged ahead of time to prevent delays. This is also when thermostat locations and condensing unit placement get finalized for service access, airflow, and noise control. Tip: ask your installer for a simple install-day agenda so everyone knows the order of work and when power will be off. If financing helps, review HVAC Financing.

Phase 4–5: Equipment & Ductwork Installation (What You’ll See)

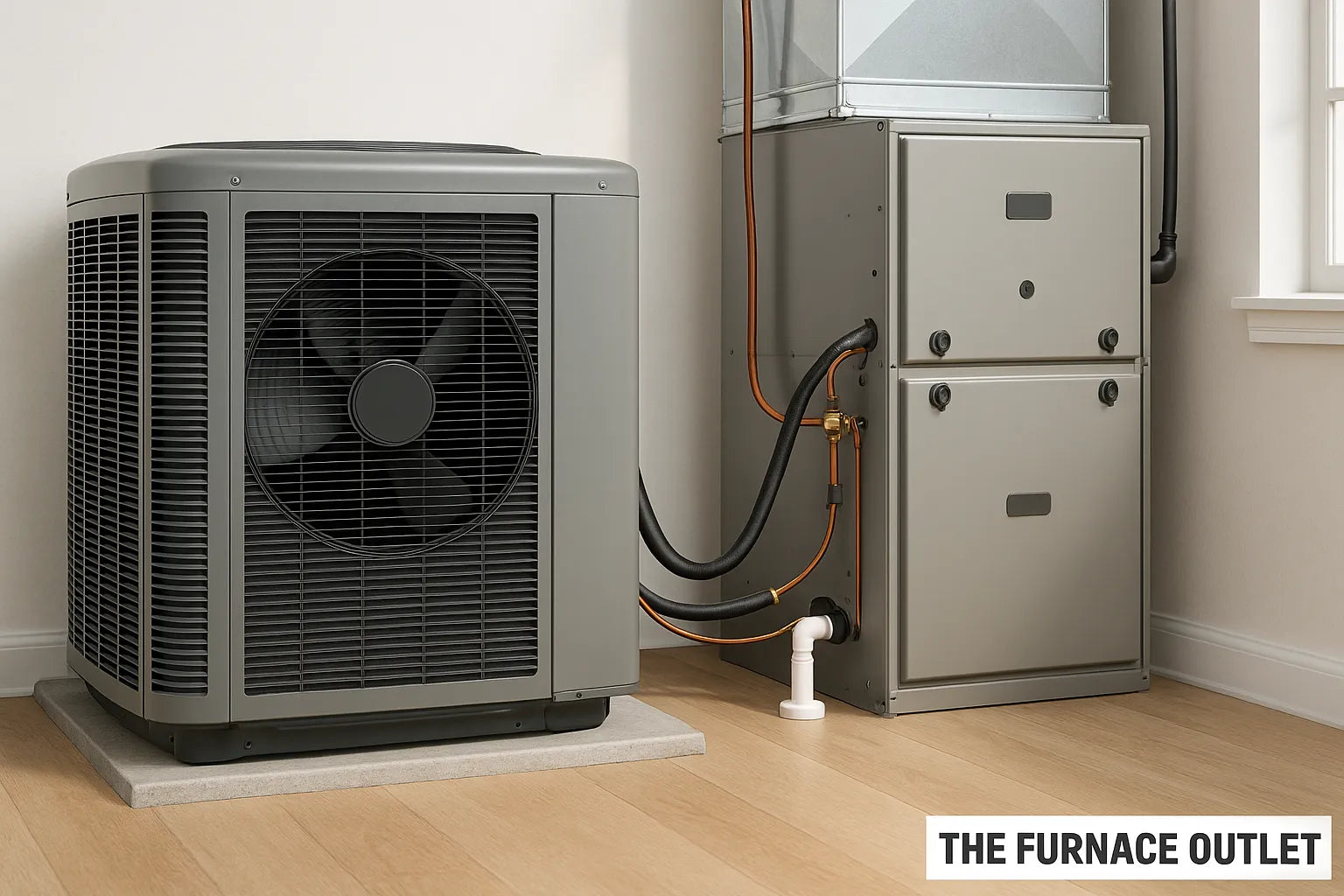

Outdoors, the condenser sits on a level pad with proper clearances for airflow and service. Indoors, the evaporator coil or air handler is set in the attic, basement, or a closet and connected to the plenum. Technicians route line sets—the larger insulated suction line and the smaller liquid line—through a sealed wall penetration (usually 2–2.5 inches). Lines are supported every 4–6 feet to prevent kinks and vibration. For existing ducts, pros seal leaks, resize where needed, and add new supplies/returns if a room was starving for air. New ducts get clean cutouts for registers, and good crews keep dust to a minimum.

Want to see equipment families that fit common layouts? Browse R-32 air handler systems or full package units

Phase 6–7: Electrical, Controls, Evacuation & Refrigerant Charge

Electricians connect the outdoor unit to the main panel with the right breaker and wire size, and mount a service disconnect near the condenser (per NEC). Low-voltage wiring links the thermostat to indoor and outdoor units. After wiring, the techs evacuate the refrigerant circuit using a vacuum pump to 200–500 microns, then perform a decay test to make sure the vacuum holds—this proves the lines are dry and tight. Only then do they weigh in the refrigerant charge to the manufacturer’s spec. Over- or under-charging can reduce efficiency and shorten compressor life. A final leak check with an electronic detector adds insurance. If you want a quick walkthrough of these steps, our Video has helpful overviews, and the HVAC Tips section explains what numbers to expect on a manifold gauge and micron gauge.

Phase 8–9: Condensate Drainage, Start-Up Testing & Commissioning

Moisture pulled from indoor air flows through a primary condensate drain to a floor drain or pump. A secondary drain port gets a safety float switch that shuts the system down if the main line backs up—this protects ceilings and floors. Start-up testing includes:

-

Measuring supply/return temperatures for a solid delta-T

-

Verifying airflow across the coil

-

Checking static pressure in the ducts

-

Confirming thermostat operation and safety controls

-

Recording amperage draw and system pressures

Techs let the system run 15–20 minutes to stabilize, then fine-tune fan speeds or charge as needed. You should receive documented readings. Keep these in your homeowner folder; they help future techs spot changes fast. For extra learning, scan recent how-to posts in HVAC Tips about airflow and maintenance.

Phase 10: Final Inspection, Timeline, Cost & How to Prepare

Local inspectors verify code compliance and safe wiring. Your contractor then gives a system walk-through: how to use the thermostat, when to change filters, and what maintenance the warranty requires. Typical timelines: like-for-like installs in 4–8 hours, new ductwork in 1–2 days, and complex multi-zone jobs in 2–3 days. Costs vary with efficiency rating, size, duct changes, and electrical work; permits and accessories add to the total. For smoother installs:

-

Clear work areas and protect valuables.

-

Be available for questions.

-

Plan for downtime during power/water shutoffs.

-

File your warranty and keep manuals.

FAQs

How long does central air installation take?

Most replacements finish the same day (4–8 hours). New ducts or multi-zone systems can take 1–3 days.

What size AC do I need?

There’s no one-size answer. Ask for a Manual J load calculation. It looks at your home’s size, insulation, windows, sun, and more.

Why is duct design a big deal?

Ducts move the cooling. Manual D makes sure each room gets the right CFM so temperatures stay even and noise stays low.

Do I really need a vacuum to 200–500 microns?

Yes. That deep vacuum and a decay test remove air and moisture, which helps your compressor last longer.

Is R-32 worth considering?

Many homeowners pick R-32 for better efficiency and lower global warming potential. See our R-32 packages.

What should I do before the crew arrives?

Clear paths, secure pets, and be ready to decide on thermostat location or grill placement. Check our Help Center for a short prep list.