A 7.5 ton packaged AC and gas furnace unit like the Daikin Light Commercial 7.5 Ton Packaged System (DFG0904DM00001S) isn’t a small piece of equipment. At close to 1,000 pounds and the size of a small car engine block, you can’t just “find a corner” for it.

Whether it’s going on your rooftop or a ground-level utility pad, you’ll need to plan ahead for weight, space, airflow, and service access. Let me walk you through the details so you don’t run into costly installation surprises.

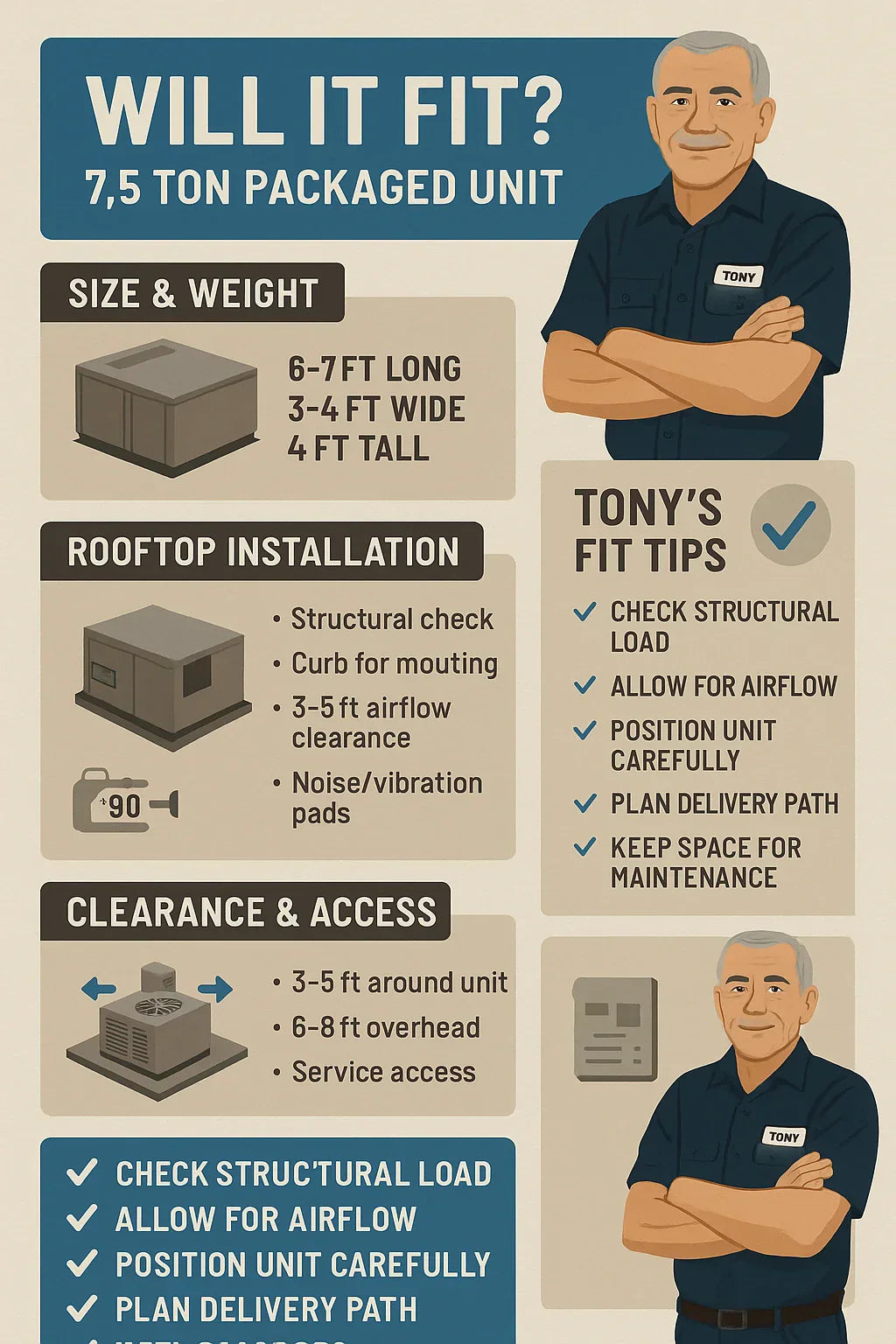

📦 How Big Is a 7.5 Ton Packaged Unit?

Most commercial 7.5 ton packaged units fall into these ranges:

-

Length: 6–7 feet

-

Width: 3–4 feet

-

Height: 4 feet

-

Weight: 900–1,000 pounds

👉 That’s about the footprint of a large pallet or a compact pickup truck bed, but much heavier.

📌 Carrier’s commercial rooftop unit specs and Trane’s packaged unit data confirm these typical dimensions.

🏗️ Rooftop Installation Requirements

Rooftop installs are common for commercial packaged units — but they come with special considerations.

1. Structural Load

-

A roof must be able to handle at least 1,000 pounds in one spot.

-

Many buildings require an engineer’s approval before a crane sets the unit.

2. Mounting Curb

-

A roof curb (metal frame) is needed for proper installation.

-

Curb must match unit footprint (6x4 ft range) and be level.

3. Clearance for Airflow

-

3–5 ft clearance on all sides for airflow.

-

No obstructions above the discharge air section.

4. Noise & Vibration

-

Install vibration isolators or neoprene pads to reduce sound inside the building.

👉 Tony’s tip: Never set units back-to-back without space. Starved airflow = burned-out compressors.

📌 ASHRAE design standards require rooftop units to be spaced properly for airflow and service access.

🏢 Ground-Level Installation Requirements

Not every business has the roof strength or design for a packaged unit. Ground installs are the alternative.

1. Utility Pad Size

-

Pad should be at least 1 ft larger than unit footprint.

-

For a 6x4 ft unit, pad should be 7x5 ft minimum.

2. Pad Strength

-

Concrete thickness: 4–6 inches reinforced.

-

Designed to hold 1,000+ pounds without shifting or cracking.

3. Clearance from Structures

-

At least 3 ft from walls/fences for airflow.

-

At least 10 ft from windows (to avoid exhaust recirculation).

4. Drainage

-

Pad should be slightly raised to prevent water pooling.

👉 Tony’s tip: Don’t pour a cheap, thin pad. I’ve seen units sink into soft ground — not a fun fix.

📌 Energy.gov central AC installation guidance highlights pad leveling and drainage as key to ground installs.

📐 Clearance & Service Access

Beyond fitting the box, you need to leave room for technicians.

-

3–5 ft clearance on all sides for airflow.

-

6–8 ft overhead clearance for service or crane lifts.

-

Accessible panels: make sure techs can reach filters, coils, and furnace doors.

📌 ACCA Quality Installation Standards emphasize proper service clearances as critical for both performance and warranty.

👉 Tony’s tip: Don’t wedge it in a corner. If your tech can’t open the panel, your repair bill doubles.

⚠️ Common Fit Mistakes

I’ve seen more than a few jobs go sideways because someone didn’t think ahead.

-

Doorways and hatches: The unit can’t even get inside the building to the roof.

-

Undersized utility pad: Unit sinks or cracks the slab.

-

Too close to walls/other units: Starves airflow, reduces efficiency.

-

Blocked service access: Techs can’t reach components = costly fixes.

📌 HVAC cost guide notes that poor planning leads to unexpected install costs.

🏙️ Real-World Examples

Example 1: Rooftop Retail Store (5,000 sq. ft.)

-

Daikin 7.5 ton unit installed on engineered curb.

-

Structural reinforcement: $2,500.

-

Clearance: 5 ft around unit.

-

Result: Smooth airflow, easy service access.

Example 2: Ground-Level Restaurant (3,800 sq. ft.)

-

Installed on 8x5 ft concrete pad, raised 6 inches.

-

Drainage added to avoid water pooling.

-

Pad cost: $1,200.

-

Result: Stable and easy to service, quieter inside dining area.

Example 3: Medical Office Rooftop (4,200 sq. ft.)

-

Two 7.5 ton units placed too close together.

-

Efficiency dropped, compressors overheated.

-

Fix: $4,000 to relocate one unit for proper clearance.

👉 Tony’s lesson: It’s always cheaper to plan space right the first time.

✅ Tony’s Fit Checklist

Before you buy a 7.5 ton packaged unit, ask these questions:

-

🏗️ Can your roof handle 1,000 lbs in one spot?

-

📦 Is your pad at least 1 ft larger than the unit footprint?

-

🌬️ Do you have 3–5 ft clearance on all sides for airflow?

-

🔧 Can a technician easily reach service panels?

-

🚚 Do you have a clear delivery path (forklift, crane, or hatch)?

-

💧 Is the pad/site graded to avoid water pooling?

📊 Cost of Fit Adjustments

-

Roof reinforcement: $2,000–$5,000

-

Roof curb & installation: $500–$1,500

-

Concrete utility pad: $800–$1,500

-

Vibration pads/screens: $200–$800

👉 Tony’s tip: Budget 10–15% extra for site prep. It saves headaches down the road.

📌 Final Word from Tony

A 7.5 ton Daikin packaged unit will fit on most rooftops or pads if you plan ahead.

-

On the roof: Check structural load, use the right curb, and leave clearance.

-

On the ground: Build a strong pad, keep it clear of walls, and watch drainage.

Don’t let size intimidate you — but don’t wing it either. Measure twice, plan the install, and your unit will serve you for 15+ years without issue.

In the next topic we will know more about: Daikin vs. Carrier vs. Trane: Which 7.5 Ton Packaged System Should You Choose?