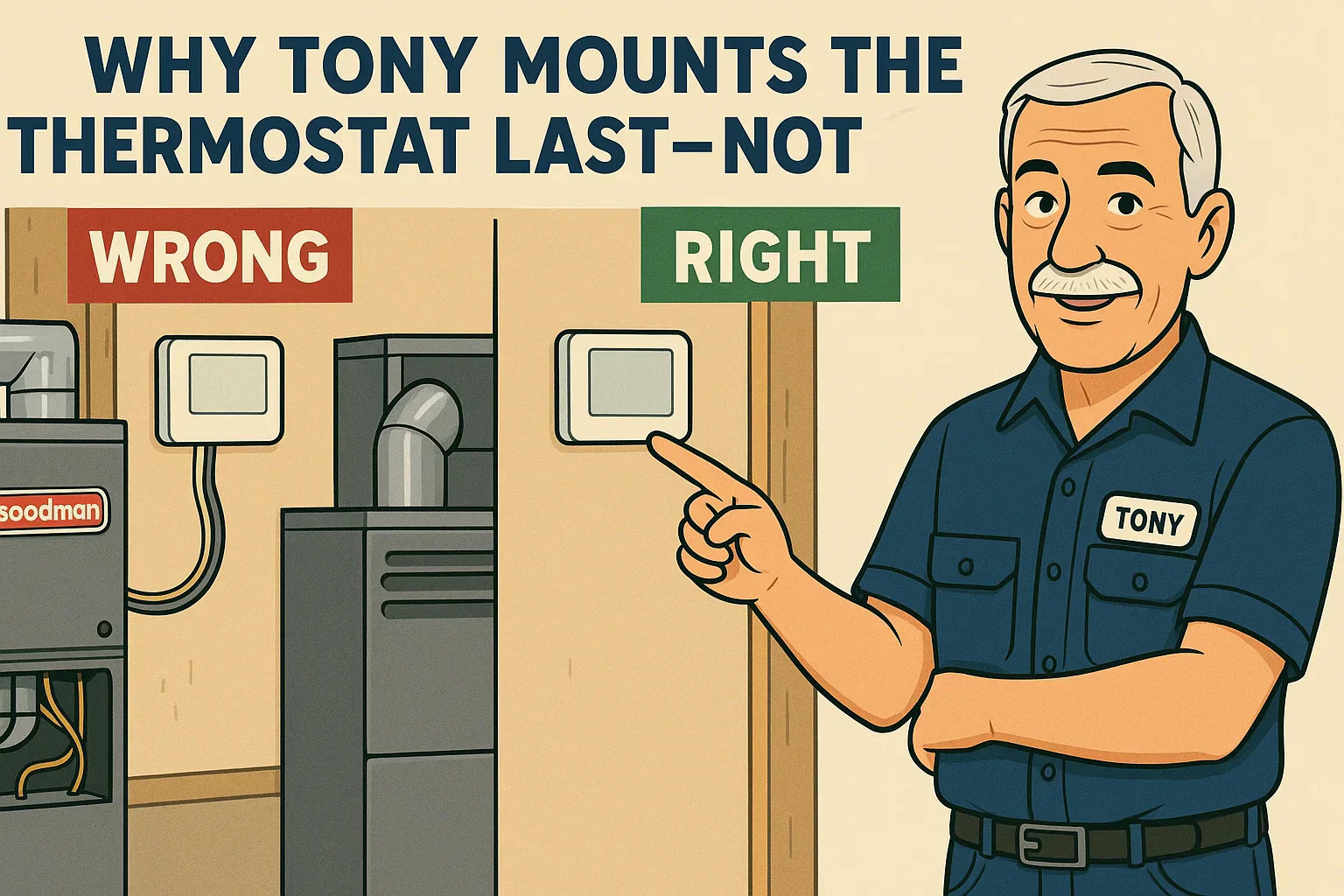

By Tony — because the thermostat is the brain of the system, and the brain doesn’t get plugged in until the body is fully built.

🧠 1. Introduction — The Thermostat Is Not Step 1. It’s Step LAST.

I’ve seen hundreds of rookies walk into a jobsite and do the exact same thing:

-

Grab the thermostat box

-

Mount it on the wall

-

Pull the wires

-

Level it

-

Program it

-

Feel proud of themselves

But here’s the problem:

Setting the thermostat first is a guaranteed way to misdiagnose the system, miswire controls, misconfigure staging, and mis-set CFM before the equipment is even installed.

The thermostat is the controller,

not the installer’s placeholder.

You don’t mount the steering wheel on a car while the engine is still being built.

You don’t wire the light switches in a house without knowing where the circuits go.

So Tony has a rule:

The thermostat gets mounted LAST — after the system is tested, set up, configured, and proven.

And once you understand why, you’ll never mount a thermostat first again.

Let’s break it down.

🏗️ 2. The Jobsite Reality: Everything Changes During Install

The thermostat wiring depends on:

-

equipment type

-

staging logic

-

heat pump configuration

-

gas furnace input

-

plenum restriction

-

airflow tuning

-

static pressure

-

zoning

-

humidifier/dehumidifier wiring

-

outdoor sensor placement

-

reversing valve logic

-

dip switches

-

communication bus wiring

-

transformer load

When you mount a thermostat first, you commit to one assumption:

The equipment setup is already known and correct.

But equipment setup always changes during install.

Here’s what always happens when rookies install thermostats first:

❌ The wiring needs to be redone

Because the system ends up being:

-

2-stage instead of 1-stage

-

Communicating instead of 24-volt

-

Heat pump + gas furnace (dual fuel) instead of cooling-only

-

Variable-speed instead of PSC

-

With accessories they didn’t account for

❌ The stat ends up on the wrong wall

Because:

-

A return grille was added

-

A supply register blows directly toward it

-

A sunlight patch heats that part of the wall

-

A door swing blocks airflow

-

The customer changed their mind

-

The designer changed airflow paths

❌ The staging setup becomes wrong

Because you haven’t tested airflow or matched tonnage to CFM yet.

❌ Programming gets erased during install

Especially when the homeowner plays with the system or power is cycled.

❌ The sub-base gets damaged

Dust, drywall, drilling, and construction beat up mounted equipment.

❌ The stat gets in the installer’s way

I’ve seen mounted thermostats get:

-

dropped

-

knocked off the wall

-

coated in dust

-

shorted

-

stepped on

-

broken by ladders

❌ The installer must remove it later anyway

Because wiring always changes once the system is running.

Mounting a thermostat first is like setting the crown molding before framing the house.

It makes no sense.

🌡️ 3. Airflow Comes First — Because Airflow Decides the Thermostat Logic

A thermostat decides:

-

CFM per ton

-

Fan speed profiles

-

Dehumidification mode

-

Staging transitions

-

Heat pump lockout

-

Gas furnace staging

-

Aux heat timings

-

Fan-only mode

-

Continuous circulation options

But all of that depends on the physical airflow.

And airflow depends on:

-

duct size

-

coil type

-

furnace model

-

blower tap settings

-

static pressure

-

return drop width

-

filter rack size

-

plenum alignment

-

supply branch count

You can’t set thermostat logic BEFORE you know:

✔️ What your static pressure is

✔️ What the real CFM is

✔️ What the coil drop actually is

✔️ How the TXV responds

✔️ How the house breathes

✔️ What the system staging actually requires

This is why Tony always installs the thermostat LAST.

Because the thermostat configuration must match:

-

REAL airflow

-

REAL refrigerant performance

-

REAL equipment operation

-

REAL duct conditions

Not the guesses made at the start of the job.

🧪 4. Tony’s Rule: The Thermostat Must Not Be Installed Until the System Runs Under Load

A thermostat should never be mounted until:

-

the equipment is installed

-

the line set is connected

-

nitrogen tests are complete

-

brazing is done

-

vacuum pulled

-

charge weighed in

-

system has run for 15+ minutes

-

airflow is measured

-

heat rise is verified

-

superheat and subcooling are confirmed

-

staging is tested

Only THEN can the thermostat be:

-

wired

-

mounted

-

programmed

-

tested

The thermostat comes AFTER:

✔️ coil install

✔️ plenum build

✔️ furnace alignment

✔️ blower setup

✔️ duct airflow measurements

✔️ static pressure readings

✔️ refrigerant charging

✔️ capacity verification

By installing the thermostat last, you guarantee:

-

correct staging

-

correct control mode

-

correct logic

-

correct airflow settings

-

correct CFM per ton

-

correct heat pump balance point

-

correct gas heat rise

-

correct compressor cycle timing

Everything depends on dialing-in the equipment FIRST.

🧩 5. Mounting the Thermostat First Causes These 9 Problems

❌ 1. Miswiring Because the System Isn’t Final Yet

You’ll end up rewiring the stat once:

-

the kit arrives

-

the zoning is added

-

the attic wiring is corrected

-

the heat pump gets installed

❌ 2. Incorrect Heat Pump Orientation (O/B Wrong)

Rookies always guess instead of test.

❌ 3. Wrong Staging Setup

Because they didn’t understand the furnace or condenser model.

❌ 4. Wrong CFM Setting

You cannot set the fan profile until you know the real static pressure.

❌ 5. Wrong Dehumidification Setup

You can’t enable low-CFM dehumidification until you see the coil frost pattern and runtime behavior.

❌ 6. Wrong Compressor Ramp Profile

Especially on variable-speed equipment.

❌ 7. Mounting in the Wrong Location

The airflow after install ALWAYS changes the correct thermostat spot.

❌ 8. Damaging the Thermostat During Construction

Dust + drywall + tools = thermostat death.

❌ 9. Having to Remove It Anyway

Reprogramming and rewiring become guaranteed.

Mounting the thermostat first wastes time and creates failures.

📋 6. Tony’s Proven Sequence — The Only One That Works Every Time

Here’s the correct jobsite order for thermostat installation:

1. Build the entire mechanical system first

Furnace → coil → plenum → line sets → drains → gas → electrical

2. Run the system under load

Cooling mode for 15–20 minutes.

3. Confirm refrigerant performance

-

superheat

-

subcool

-

coil frost pattern

-

suction temp

-

discharge temp

4. Confirm airflow

-

static pressure

-

CFM

-

heat rise

-

duct leakage

5. Wire the system based on ACTUAL staging needs

Not the assumed ones.

6. Mount the thermostat and program it LAST

Now that:

-

the system is stable

-

airflow is proven

-

refrigerant is correct

-

staging is confirmed

-

blower profiles are tuned

…the thermostat can finally be installed correctly.

🛡️ 7. Why This Prevents 95% of Thermostat-Related Callbacks

Most thermostat problems aren’t thermostat problems.

They are:

-

airflow problems

-

staging problems

-

wiring problems

-

configuration problems

-

heat pump logic problems

-

furnace setup problems

When the thermostat is installed dead last:

-

wiring is correct

-

setup is correct

-

sensors are correct

-

staging is correct

-

no drywall dust enters the stat

-

it won’t get damaged

-

no homeowner touches it prematurely

-

no wires get torn out

-

all final adjustments are accurate

It eliminates nearly ALL startup headaches.

📘 8. Verified External Technical Resources

Here are reputable, verified external resources supporting coil installation, condensate management, and TXV behavior:

-

ASHRAE Fundamentals – Coil Construction & Airflow (Technical)

https://www.ashrae.org/technical-resources/ashrae-handbook -

HVAC Drainage Code Requirements (ICC)

https://codes.iccsafe.org/ -

EPA HVAC Moisture & Condensate Guidelines

https://www.epa.gov/mold -

AHRI Air Coil Performance Standards

https://www.ahrinet.org/standards -

RSES TXV Installation & Superheat Guidelines

https://www.rses.org -

Goodman (Daikin) Coil & TXV Transition Resources

https://www.daikincomfort.com/

🏁 9. Final Thoughts — The Thermostat Doesn’t Control the System Until the System Exists

Most installers think:

“Mount the thermostat early so the customer thinks we’re making progress.”

But progress isn’t about appearances.

Progress is about doing the job right.

And doing the job right means:

Build the system first.

Tune the system second.

Mount the thermostat last.

Only when the equipment is running correctly should the system be handed over to the thermostat.

That’s how Tony does it — and that’s why he never gets called back to fix a setup mistake created on day one.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The 120k Furnace Exhaust Reality — Why Tony Rebuilds Every Vent Instead of Reusing Old PVC