By Samantha Reyes — Smart Shopper, Efficiency Detective, and the woman who learned (the hard way) that your coil can make or break your entire HVAC system.

Most homeowners believe all coils are the same.

If it fits the cabinet…

If the tonnage matches the unit…

If the installer says, “This is what we use”…

…it must be fine, right?

Absolutely not.

Because when you upgrade to high-efficiency systems—especially R-32 systems paired with High-SEER2 outdoor units—your coil becomes the center of the entire airflow equation.

The coil determines:

-

your real-world SEER2 score

-

your humidity levels

-

your compressor workload

-

your run times

-

your blower RPM

-

your overall comfort

And with R-32 refrigerant entering the U.S. market, coil design is changing faster than most installers can keep up with.

Goodman 3.5 Ton 15.2 SEER2 System

Today, I’ll walk you through exactly why R-32 coils matter, how they behave differently, and the precise “design math” I use to pair a coil correctly to a high-SEER2 outdoor unit.

If you’re buying a new system—or fixing the mistakes of a previous installation—this guide will save you from years of headaches.

Let’s dig in.

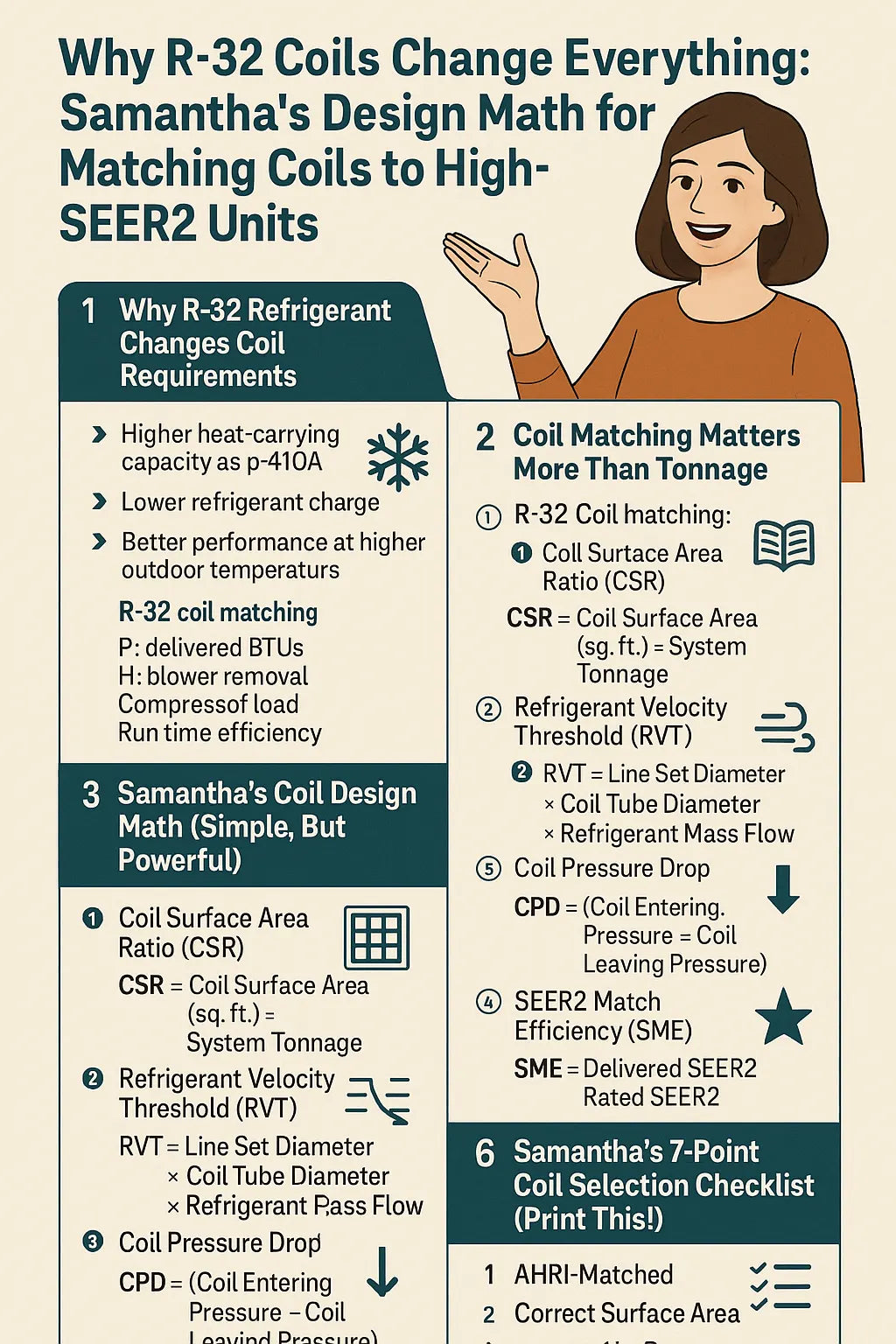

❄️ 1. Why R-32 Refrigerant Changes Coil Requirements

R-32 isn’t just “another refrigerant.”

It behaves differently inside the coil.

Here’s what makes R-32 unique:

1. Higher heat-carrying capacity

R-32 transfers heat more efficiently than R-410A.

(ASHRAE confirms its superior thermodynamic performance:

🔗 https://www.ashrae.org/technical-resources)

2. Lower refrigerant charge required

Systems use ~20–30% less refrigerant.

3. Better performance at higher outdoor temperatures

R-32 maintains efficiency during heat waves when R-410A struggles.

4. Higher operating pressures

Which means coil surfaces, tubing, and metering devices must be engineered specifically for R-32’s pressure curve.

5. Faster heat exchange

This influences coil size requirements (bigger is not always better, but mismatching is always bad).

Samantha’s translation:

R-32 coils aren’t interchangeable.

If your installer pairs “whatever fits,” your system will never reach its rated efficiency.

📘 2. Coil Matching Matters More Than Tonnage

Most homeowners think coil sizing is simple:

“If I’m getting a 3.5-ton system, I need a 3.5-ton coil.”

Nope.

And this is even more important with R-32.

**You don’t match tonnage.

You match capacity curves.**

The DOE explains that rated efficiency depends on the exact match between outdoor unit, indoor coil, and blower:

🔗 https://www.energy.gov/energysaver/energy-saver

R-32 coil matching affects:

-

actual delivered BTUs

-

humidity removal

-

blower RPM

-

compressor load

-

coil temperature drop

-

run time efficiency

-

refrigerant velocity

-

subcooling and superheat curves

If your coil is undersized:

→ weak cooling, poor SEER2 performance, coil freeze

If oversized:

→ humidity issues, short cycling, low refrigerant velocity

If mismatched:

→ everything breaks down

This is why coil math matters.

Let’s get into the formulas.

📐 3. Samantha’s Coil Design Math (Simple, But Powerful)

When designing for R-32 systems, I use four calculations:

1️⃣ Coil Surface Area Ratio (CSR)

📏 Icon: Grid / Coils

A coil’s capacity correlates to its surface area, not just its “rated tonnage.”

CSR helps ensure the coil surface can handle the refrigerant heat load.

CSR Formula:

CSR = Coil Surface Area (sq. ft.) ÷ System Tonnage

Targets for R-32 systems:

-

CSR of ≥ 3.25 sq. ft. per ton for high-SEER2

-

CSR of ≥ 3.5 sq. ft. per ton for humid climates

-

CSR of ≤ 3.0 may lead to humidity issues

You’ll find surface area data in coil spec sheets (manufacturers list it as “fin area”).

2️⃣ Refrigerant Velocity Threshold (RVT)

🌪️ Icon: Airflow arrows

R-32 is more efficient, but it also flows faster.

We need a balance:

→ Too slow = oil return issues

→ Too fast = noise + pressure imbalance

RVT Formula:

RVT = Line Set Diameter × Coil Tube Diameter × Refrigerant Mass Flow

Your installer or manufacturer provides mass-flow rates.

R-32 sweet spot:

→ V = 800–1,200 ft/min

Below 800: poor oil return

Above 1,200: noise + reduced efficiency

3️⃣ Coil Pressure Drop (CPD)

📉 Icon: Downward arrow

R-32 requires specific metering and tubing.

If CPD is too high, the blower ramps up constantly.

If CPD is too low, your refrigerant may not flash properly.

CPD Formula:

CPD = (Coil Entering Pressure – Coil Leaving Pressure)

Ideal CPD for R-32:

-

0.05–0.15 in. w.c. across the coil

ASHRAE notes that coil pressure drop is one of the leading causes of high static pressure in modern systems:

🔗 https://www.ashrae.org/technical-resources

4️⃣ SEER2 Match Efficiency (SME)

⭐ Icon: Energy star

A coil + outdoor unit MUST be AHRI-matched to achieve the published SEER2 rating.

ENERGY STAR emphasizes that AHRI pairing is mandatory for real performance

SME Formula:

SME = Delivered SEER2 ÷ Rated SEER2

If SME < 0.90,

your system is underperforming by 10% or more—often due to coil mismatch.

🏗️ 4. The 3 Coil Types You’ll See in R-32 Systems (And Which Is Best)

Let’s break them down.

🔶 A-Coils (Most Common)

Pros:

-

Compact

-

High surface area

-

Stable airflow path

-

Compatible with most R-32 systems

Best for:

-

2-story homes

-

High-efficiency systems

-

Heat pump configurations

🔷 N-Coils (Good in Tight Spaces)

Pros:

-

Large refrigerant contact area

-

Efficient in high-SEER2 setups

Cons:

-

Restrictive airflow

-

Higher coil pressure drop (bad for ECM motors)

Best for:

-

Small mechanical closets

-

Limited return-air situations

⬛ Slab Coils (Not Ideal for R-32)

Cons:

-

Lower surface area

-

Poor humidity removal

-

Difficult to clean

-

Not ideal for variable-speed or high-efficiency systems

Use only if:

-

Cabinet height restrictions leave no alternatives

🔧 5. R-32 + High-SEER2 = Why Coil Choice Is Everything

A high-SEER2 system is designed to:

✔ run longer

✔ run quieter

✔ modulate airflow

✔ remove more humidity

✔ reduce energy usage

But none of those benefits matter if the coil is mismatched.

Here’s what happens with a bad coil match:

❌ Efficiency Loss

Your 17.2 SEER2 system becomes a 13.5 SEER2 system.

❌ Humidity Problems

Coil size directly impacts latent capacity.

❌ High Static Pressure

ECM blowers ramp to fight restriction.

❌ Compressor Overheat

R-32’s higher pressures require coil stability.

❌ Poor Run Times

System short-cycles.

❌ Refrigerant Imbalance

Too little coil volume = flash gas

Too much = poor velocity

ASHRAE’s coil design notes show that coil geometry dramatically impacts performance:

🔗 https://www.ashrae.org/technical-resources

📊 6. Samantha’s 7-Point Coil Selection Checklist (Print This!)

Before you install ANY R-32 system, verify:

1. AHRI-Matched

Coil + unit must be AHRI-certified as a pair.

2. Correct Surface Area

≥ 3.25 sq. ft./ton for high-SEER2

≥ 3.5 sq. ft./ton for humid climates

3. Acceptable Pressure Drop

0.05–0.15 in. w.c. across coil

4. Compatible TXV or EEV

Metering device must match R-32 characteristics.

5. Proper Airflow Rating

350–400 CFM per ton depending on climate

6. Coil Geometry Suits Application

A-coil for most homes

N-coil for small cabinets

Avoid slab coils when possible

7. Moisture Removal Rating

Look for a coil with strong latent performance.

The DOE confirms that coil design directly impacts humidity removal efficiency:

🔗 https://www.energy.gov/energysaver/energy-saver

🎯 7. Real-World Example: Matching a 3.5-Ton R-32 System

Let’s apply the math.

System: 3.5-ton high-SEER2 R-32

Required airflow: ~1,400 CFM

Climate: Mixed-humid (Midwest or Southeast)

Coil Requirements:

-

Surface area ≥ 11.5 sq. ft.

-

Coil pressure drop ≤ 0.12

-

A-coil recommended

-

TXV designed for R-32

-

AHRI matched for 15.2 SEER2 or above

-

Blower capable of 1,400 CFM at ≤ 0.5 in. w.c.

If any of these fail, your system loses efficiency IMMEDIATELY.

🧠 8. What Happens When You Get Coil Matching RIGHT?

This is where the magic happens.

When the coil is correct:

✔ Lower Blower RPM

Less static pressure = quieter home.

✔ Lower Bills

SEER2 maintains its real-world value.

✔ Better Humidity Removal

Coil surface area + refrigerant flow = comfort.

✔ Longer Compressor Life

Proper refrigerant velocities stabilize pressure circuits.

✔ No Hot or Cold Rooms

Airflow is predictable and balanced.

✔ Less Dust

Lower static pressure reduces infiltration.

✔ Calm, Even Temperatures

The home finally feels “one temperature everywhere.”

This is why coil choice matters more than anything else.

💬 Final Thoughts — The Coil Is the System’s Silent Architect

Most people spend thousands choosing:

-

the right furnace

-

the right AC

-

the right refrigerant

-

the right efficiency rating

…and then let the installer pick the coil without a discussion.

That’s like buying a luxury car and letting someone else choose the engine.

If the coil is wrong, the system is wrong.

If the coil is right, everything else works effortlessly.

R-32 coils truly do change everything—if you pair them correctly.

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: Your Home Has ‘Pressure Personalities’: Samantha’s Guide to Balancing Open-Concept vs. Compartmental Layouts