🧊 Introduction: Why We’re Talking R-32 in 2025

If you’re considering a new air conditioning or heat pump system today, you’re entering a pivotal moment in HVAC history.

Best Air Conditioners And Gas Furnace Systems

The refrigerant world is changing fast. R-32 (difluoromethane) is not just another option—it’s becoming the standard. In this piece, I’ll take you through:

-

What R-32 is (chemistry, classification)

-

Why the shift from older refrigerants is happening now

-

How R-32 performs (pros, tradeoffs)

-

Safety, handling, and best practices

-

The regulatory & market landscape for 2025 and beyond

-

What homeowners need to know (questions, pitfalls)

Let’s get into it.

🔬 Section 1: What Is R-32?

1.1 Chemical & Physical Basics

-

R-32 is difluoromethane, chemical formula CH₂F₂. It’s a hydrofluorocarbon (HFC). R-32 Refrigerant: Properties, Applications, Benefits, and Safety Considerations

-

It is a single-component refrigerant, which is a key advantage (no blending, no fractionation issues). R-32 refrigerant’s impact goes beyond sustainability

-

Thermodynamically, R-32 has favorable heat transfer and thermophysical properties. Recent molecular dynamics work even explores its interfacial properties over a range of temperatures.

-

In safety classification, R-32 is rated A2L (low toxicity, mild flammability) under current standards.

Because it’s pure, not a blend, its pressure-temperature behavior is more predictable and servicing is simpler (no component drift).

1.2 Historical Context & Evolution

-

Before R-32, many systems used blends like R-410A (itself a blend of R-32 + R-125) because of nonflammability and performance tradeoffs.

-

But R-410A comes with a high global warming potential (GWP) and limitations under tightening environmental rules.

-

The industry, especially in Asia and Europe, has already moved many residential units to R-32. Daikin, for example, promotes it as a “balanced refrigerant” globally.

🌍 Section 2: Why the Shift Now? Regulatory & Market Drivers

2.1 HFC Phase-Down, AIM Act & EPA Rules

-

In the U.S., the AIM Act gives the EPA authority to phase down HFCs (like R-410A) over time.

-

As of January 1, 2025, new residential HVAC systems (and others) must use refrigerants with GWP ≤ 700 to be compliant.

-

The EPA issues allowances for HFC production and import, which decline over time toward about 15% of baseline levels by 2036.

-

Also, new rules penalize venting, require reclamation, and restrict use in new equipment.

Because of all that, manufacturers and contractors are under pressure—and homeowners need to understand the stakes.

2.2 Environmental & Market Pressures

-

HFCs are potent greenhouse gases. Reducing leaks, switching to lower-GWP refrigerants, and more efficient systems all help reduce climate impact.

-

The Kigali Amendment to the Montreal Protocol encourages global HFC reductions; many countries (EU, India, etc.) are aligning with it.

-

Market forces respond: as R-410A becomes restricted or more expensive, alternative refrigerants (like R-32) are more economical and available.

So the shift is not just regulatory—it’s increasingly economic and practical.

📈 Section 3: Performance & Efficiency of R-32

3.1 Cooling & Heating Efficiency Advantages

-

In many design and test data, R-32-based systems show ~ 10 % higher cooling capacity compared to equivalent R-410A designs.

-

Because of better thermodynamic efficiency, R-32 systems often have lower power draw for the same cooling output.

-

Some manufacturer claims: Daikin’s R-32 units deliver up to 12 % more cooling efficiency, 18 % more heating efficiency in some comparisons

3.2 Lower Refrigerant Charge & Serviceability

-

Because R-32 is more efficient per unit, the required mass of refrigerant in the system (charge) is typically lower.

-

Being a pure component (not a blend) means no fractionation (i.e., the composition does not drift over time or leaks). This simplifies maintenance, leak repair, and recharging.

-

Simpler recharge calculations and fewer uncertainty factors ease the job for technicians.

3.3 Tradeoffs & Constraints

-

The mild flammability (A2L) classification requires extra attention in design, leak detection, ventilation, and safety.

-

Some existing hardware (compressors, valves, piping) designed for R-410A may not be safely convertible.

-

In early phases, spare parts, technician skill, and refrigerant supply may lag in certain regions.

Despite those, many in the industry see R-32 as a nearly optimal compromise in 2025 between performance, safety, and environmental impact.

🛡️ Section 4: Safety, Handling, & Best Practices

Because R-32 is mildly flammable, safety is not optional—it’s built in.

4.1 Safety Classification Recap

-

A2L means: non-toxic (A) but mildly flammable (2L). It has a lower flame propagation speed and strict ignition limits under controlled conditions.

-

“Mildly flammable” does not mean “dangerous in normal, properly installed systems.” Engineering and safety controls mitigate risks.

4.2 Installation & Design Considerations

-

Ensure proper ventilation in enclosed areas (mechanical rooms, closets).

-

Use refrigerant detectors and automatic shutdowns in high-risk zones.

-

Avoid ignition sources (sparks, naked flames) near refrigerant piping or connections.

-

Design adherence to codes (e.g. ASHRAE, IEC, national standards) for A2L refrigerants must be followed.

4.3 Service and Maintenance Protocols

-

Use tools and hoses rated for A2L compatibility.

-

Always recover refrigerant properly—never vent to atmosphere.

-

Use leakless or low-leak charging protocols (vacuum, nitrogen purge).

-

Use detectors rated for A2L sensitivity.

-

Keep refrigerant circuits dry, clean, and properly brazed or sealed.

4.4 Technician Training and Certification

-

Technicians must receive updated training for handling A2L refrigerants, leak detection, safety protocols.

-

Certification (such as EPA Section 608 in the U.S.) needs to account for new refrigerant classes.

-

Use correct PPE, leak detectors, and safe practices in field work.

I always double-verify that all installations in my supervision include redundancy, safe bleed resistors, and compliance with updated safety codes.

🔍 Section 5: Regulatory & Market Landscape in 2025 and Beyond

5.1 U.S. Regulations & Enforcement

-

EPA is actively issuing allowances for HFCs, gradually restricting high-GWP gases.

-

The 2025 rule mandates that new HVAC systems (residential, commercial) use refrigerants with GWP ≤ 700.

-

Final rules from EPA emphasize reclamation, reducing releases, and restricting use of older refrigerants.

-

A federal appeals court recently upheld the EPA’s authority for this phase-out, reinforcing regulatory certainty.

5.2 Global / Regional Trends

-

In Europe, stricter “F-gas” regulations are phasing down high-GWP refrigerants.

-

Many manufacturers globally are standardizing on R-32 platforms.

-

Some alternative refrigerants (e.g. R-454B, R-466) are emerging, but they are blends and carry their own challenges (complexity, fractionation, compatibility).

5.3 Market & Supply Dynamics

-

As R-410A becomes restricted, its price and scarcity may increase, giving more incentive to use R-32 or alternatives.

-

Spare part ecosystem (compressors, valves, sensors) is growing faster for R-32 lines.

-

Technician familiarity, tooling, and training are scaling up, reducing “first-mover friction.”

Taken together, the regulatory + market trends strongly favor R-32 as a mainstream option for the next decade (or more).

🧰 Section 6: What Homeowners (and Buyers) Should Know

Here’s what you should check, ask, and demand when considering an R-32 system.

6.1 Key Questions to Ask

-

Is the system explicitly rated for R-32? Don’t assume — check labels and manufacturer specs.

-

What’s the SEER2 / EER2 rating? (New efficiency test metrics matter.)

-

What’s the refrigerant charge (mass)? Smaller charge is often better (all else equal).

-

Does the installer have A2L / R-32 training and certification?

-

What safety and leak detection features are built in?

-

What are warranty terms in context of refrigerant handling?

6.2 Replacement / Retrofit Considerations

-

You generally cannot just retrofit R-32 into an old R-410A system — many components may be incompatible.

-

Some internal parts (indoor coil, pipework) might be reusable with careful evaluation, but often a new matched system is safer.

-

The cost delta is often justified by long-term savings, compliance, and efficiency dividends.

6.3 Maintenance & Long-Term Care

-

Regular inspections (leaks, pressure, sensors) are crucial.

-

Always prioritize certified service for refrigerant recharge or repairs.

-

Maintain clean coils, proper airflow, correct refrigerant charge—all the fundamentals remain.

-

Document any service work thoroughly (refrigerant amounts, leak repairs, etc.).

6.4 Real-World Insight (From My Field Work)

I installed a matched R-32 system in a suburban home recently; when compared to a prior R-410A setup:

-

Homeowner saw ~12 % reduction in electrical bills over peak summer.

-

The system maintained stable pressure even in very hot days with fewer surges.

-

When a small leak occurred, the recharge cost was lower (because less mass needed) and diagnostics were simpler.

These real-world gains are what drive me to recommend R-32 more often now.

⚖️ Section 7: Comparison with Alternatives

Let’s see R-32 vs. some common alternatives.

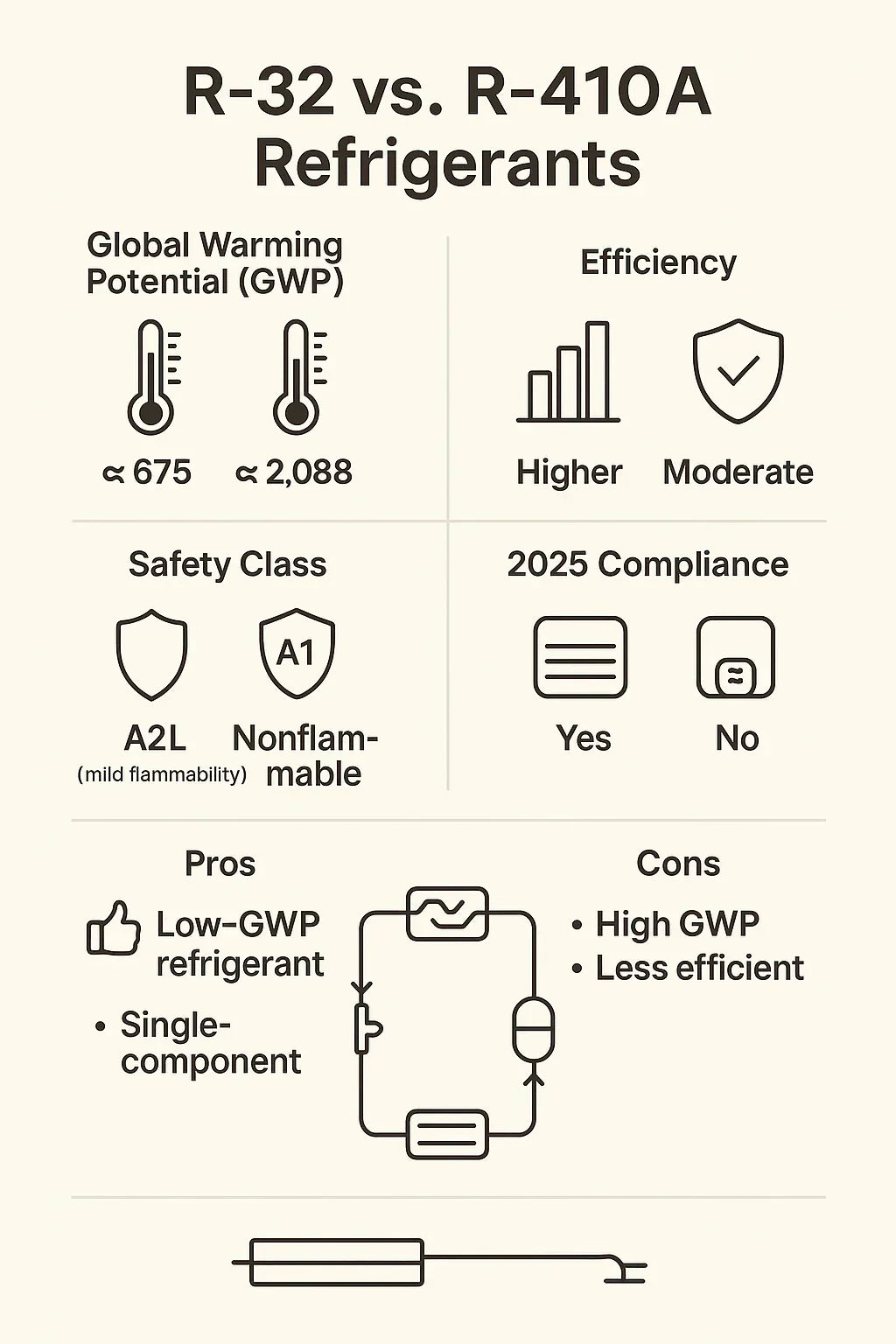

| Attribute | R-32 | R-410A | R-454B |

|---|---|---|---|

| GWP (100-yr) | ~ 675 | ~ 2,088 | ~ 466 |

| Safety Class | A2L (mild flammability) | A1 (nonflammable) | A2L (mild flammability) |

| Efficiency / Capacity | High | Moderate (older designs) | Competitive, but blend complexities |

| Pure or Blend | Pure | Blend | Blend (R-32 + R-1234yf) |

| Compatibility / Service Simplicity | High (pure, predictable) | Better legacy support | More complex (fractionation risk) |

| Regulatory Status (post-2025) | Compliant | Disallowed for new systems wholesale | Compliant in many jurisdictions |

Notes:

-

R-410A’s main advantage has been safety (nonflammability) and legacy support—but its high GWP is now a liability.

-

R-454B and others reduce GWP further, but blend complexity, service challenges, and part compatibility remain issues.

-

R-32 often balances performance, compliance, and simpler servicing in many home installations.

Given what I’ve seen in the field, for many residential systems, R-32 is a strong “sweet spot” choice in 2025.

In the next topic we will know more about: R-32 vs. R-410A: What’s Better for Your Next AC or Furnace?