When I decided to add a Goodman CAP-2L-AM louvered ceiling access panel to my home, I thought it would be a quick upgrade. After all, it’s just a small panel that helps with filter changes and airflow, right? But when I first held it up to the opening in my ceiling, it didn’t fit the way I expected. One side gapped slightly, and the panel didn’t sit flush with the drywall.

I panicked for a moment, worried I had bought the wrong size. But after a little troubleshooting—and a few handy tips from my HVAC technician—I learned how to identify and fix common fit issues. Today, my panel fits perfectly, looks seamless, and functions exactly as intended.

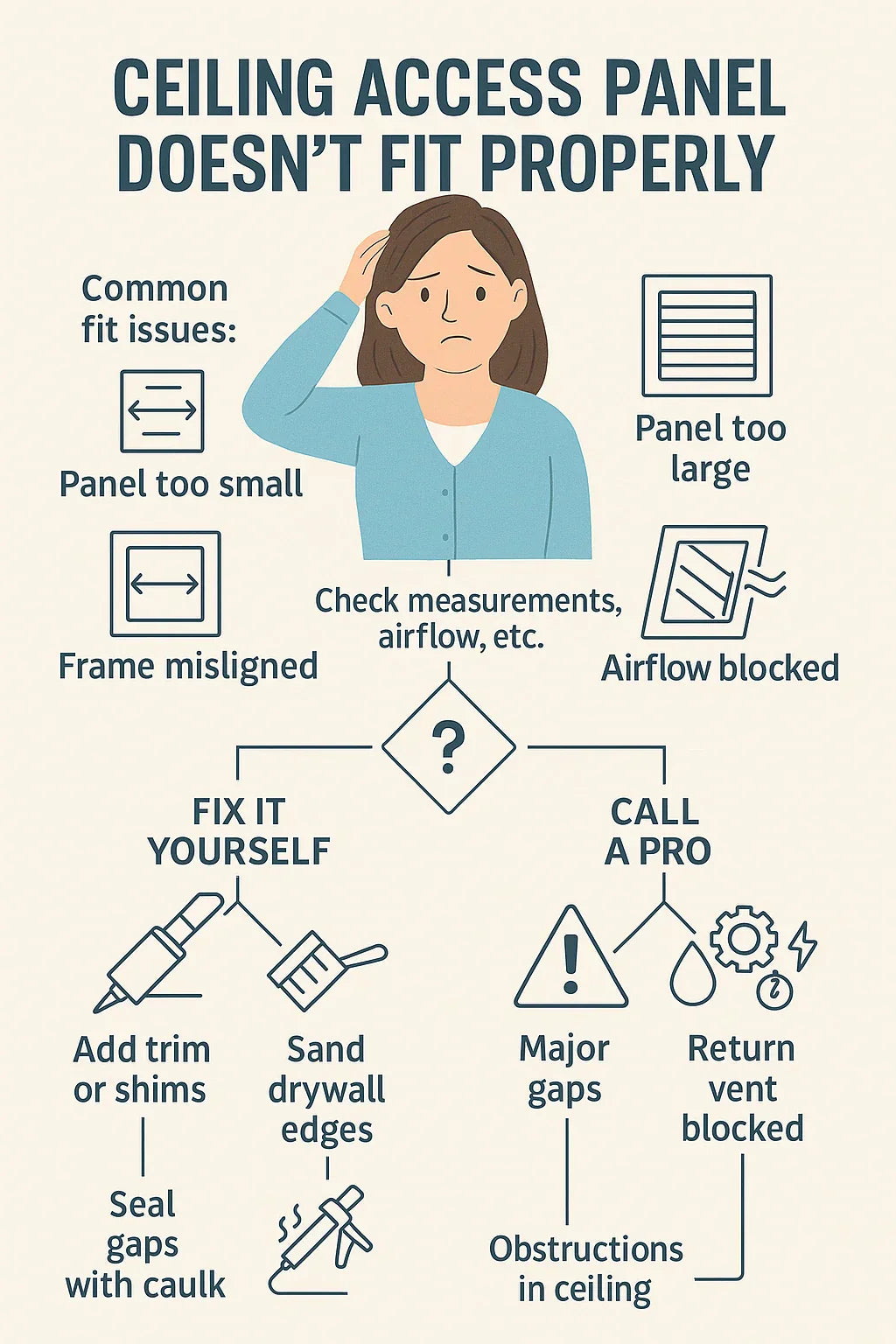

If you’re struggling with a ceiling access panel that doesn’t fit properly, don’t worry—you’re not alone. In this guide, I’ll walk you through common fit problems, how to troubleshoot them, and when it’s best to call in a professional.

🔎 Common Fit Problems with Ceiling Access Panels

Ceiling access panels are designed to make life easier, but a poor fit can cause frustration. Here are the most common issues homeowners run into:

-

Panel Too Small for the Opening

-

Leaves visible gaps around the frame.

-

Can cause air leakage and wasted energy.

-

-

Panel Too Large for the Space

-

Won’t fit into the cutout.

-

May force drywall cracking during installation attempts.

-

-

Misaligned Frame

-

Joists or ceiling beams interfere with proper placement.

-

Causes the panel to sit unevenly.

-

-

Louvers Blocked or Restricted

-

Panel positioned incorrectly, preventing airflow.

-

May result in noisy operation or reduced efficiency.

-

-

Door Doesn’t Close Properly

-

Hinges misaligned or latch obstructed.

-

Creates gaps and rattling during HVAC cycles.

-

👉 According to the International Code Council, access panels must be “readily accessible” for servicing. A poor fit can make your installation non-compliant with building codes.

📏 How to Check if Your Panel Fits Correctly

Before you attempt any fixes, confirm whether the problem is installation-related or if you’ve got the wrong panel size altogether.

Steps:

-

Measure Ceiling Opening – Compare the cutout dimensions with the panel’s manufacturer specs.

-

Check Squareness – Use a carpenter’s square or level to ensure the opening isn’t crooked.

-

Test Closure – Open and close the panel door. If it catches or rattles, alignment may be off.

-

Inspect Gaps – Look for air leaks, visible seams, or uneven pressure around the frame.

👉 Tip from my own experience: don’t forget to measure both the outer frame size and the inner louver opening—both affect how the panel will fit and perform.

🛠️ DIY Fixes for Minor Fit Issues

If your panel is close to fitting but not quite right, you can often fix it without replacing the whole thing.

1. Gaps Around the Panel

-

Use trim pieces or caulk to close small gaps.

-

White paintable caulk blends the panel seamlessly with your ceiling.

2. Oversized Ceiling Opening

-

Add drywall shims or wood strips to shrink the opening slightly.

-

Then re-secure the panel frame into the adjusted space.

3. Misaligned Frame

-

Loosen screws, reposition the frame, and re-level before tightening.

-

Use shims for support if joists are uneven.

4. Stuck or Rattling Door

-

Adjust latch tension.

-

Add weatherstripping for a snug, rattle-free closure.

💡 When I had a tiny gap on one corner, a bead of caulk and a coat of ceiling paint made it invisible.

❌ When Not to DIY

Sometimes, it’s safer and smarter to call in a professional.

-

Airflow Blockage – If the panel restricts HVAC return air, it can cause efficiency loss or system strain.

-

Hidden Obstructions – If you accidentally cut into ductwork, plumbing, or wiring.

-

Code Compliance Issues – Some setups (fire-rated panels, multifamily units) require licensed installation.

👉 According to the DOE, improper airflow can reduce HVAC efficiency by up to 30%. That’s not a risk worth taking.

🌬️ Airflow Issues with Poor Fit

One of the biggest risks of a poorly fitting panel is restricted airflow.

-

Too Small = Choked Return Air – Your HVAC blower struggles, creating noise and energy waste.

-

Too Large = Leaks and Bypass Air – Unconditioned air sneaks in, reducing system performance.

-

Improperly Aligned Louvers – Causes pressure imbalances, whistling sounds, and uneven comfort.

👉 Balanced airflow is key, as ASHRAE highlights in their standards for indoor comfort.

👩🔧 Samantha’s Troubleshooting Checklist

Whenever I help friends or neighbors troubleshoot their ceiling panels, I share this step-by-step guide:

-

✅ Measure ceiling cutout and compare to panel specs.

-

✅ Confirm panel type (solid vs. louvered) matches HVAC needs.

-

✅ Inspect alignment with joists and surrounding drywall.

-

✅ Check louvers for airflow clearance.

-

✅ Seal edges with caulk to prevent air leaks.

-

❌ If airflow is restricted, call an HVAC professional.

💲 Cost of Fixing vs. Replacing

Here’s what you can expect if you run into fit issues:

| Solution | DIY Cost | Pro Cost |

|---|---|---|

| Caulking gaps | $10–$20 | N/A |

| Adding drywall shims | $20–$40 | $150–$200 |

| Adjusting misalignment | Free (time) | $150–$250 |

| Full panel replacement | $30–$120 | $200–$400 (with labor) |

👉 HomeAdvisor reports that drywall repair alone averages $200–$500—so installing a panel correctly from the start saves money.

✅ Preventing Fit Problems in the First Place

The best troubleshooting is prevention. Here’s how to avoid fit headaches:

-

Measure Twice, Buy Once – Confirm both the outer frame size and the opening size.

-

Choose Compatible Panels – For Goodman HVAC, use CAP-2L-AM for standard return air setups.

-

Plan Placement Early – Align with joists and avoid obstructions.

-

Check Manufacturer Specs – Goodman provides detailed dimensions for each panel model.

💡 My lesson learned: I always triple-check dimensions before purchasing panels for friends or family now.

👩🎨 Samantha’s Experience

I’ll be honest: my first attempt at installing a ceiling access panel was messy. The opening was slightly off, and the panel rattled when my HVAC kicked on. But after reseating the frame, sealing the gap, and painting the edges, it looked like it had always been part of the ceiling.

That’s why I tell homeowners not to give up when the panel doesn’t fit at first. With a little troubleshooting, you can almost always fix it—and enjoy the benefits of easier maintenance, quieter operation, and better airflow.

🏁 Conclusion

A ceiling access panel that doesn’t fit properly isn’t just an eyesore—it can affect airflow, energy efficiency, and system performance.

-

Minor gaps can be fixed with trim or caulk.

-

Oversized openings can be shimmed or adjusted.

-

Misalignments can often be corrected with patience.

-

But if airflow is compromised, it’s best to call a pro.

From my own experience, switching to the properly sized Goodman CAP-2L-AM was worth it. The fit was perfect, the noise disappeared, and maintenance became effortless.

👉 My takeaway: Don’t underestimate the importance of fit. It’s a small detail with a big impact on comfort, efficiency, and aesthetics.

In the next topic we will know more about: Cost Guide: How Much Should You Budget for Ceiling Access Panels and Installation?