🧰 Introduction: Don’t Panic, Diagnose First

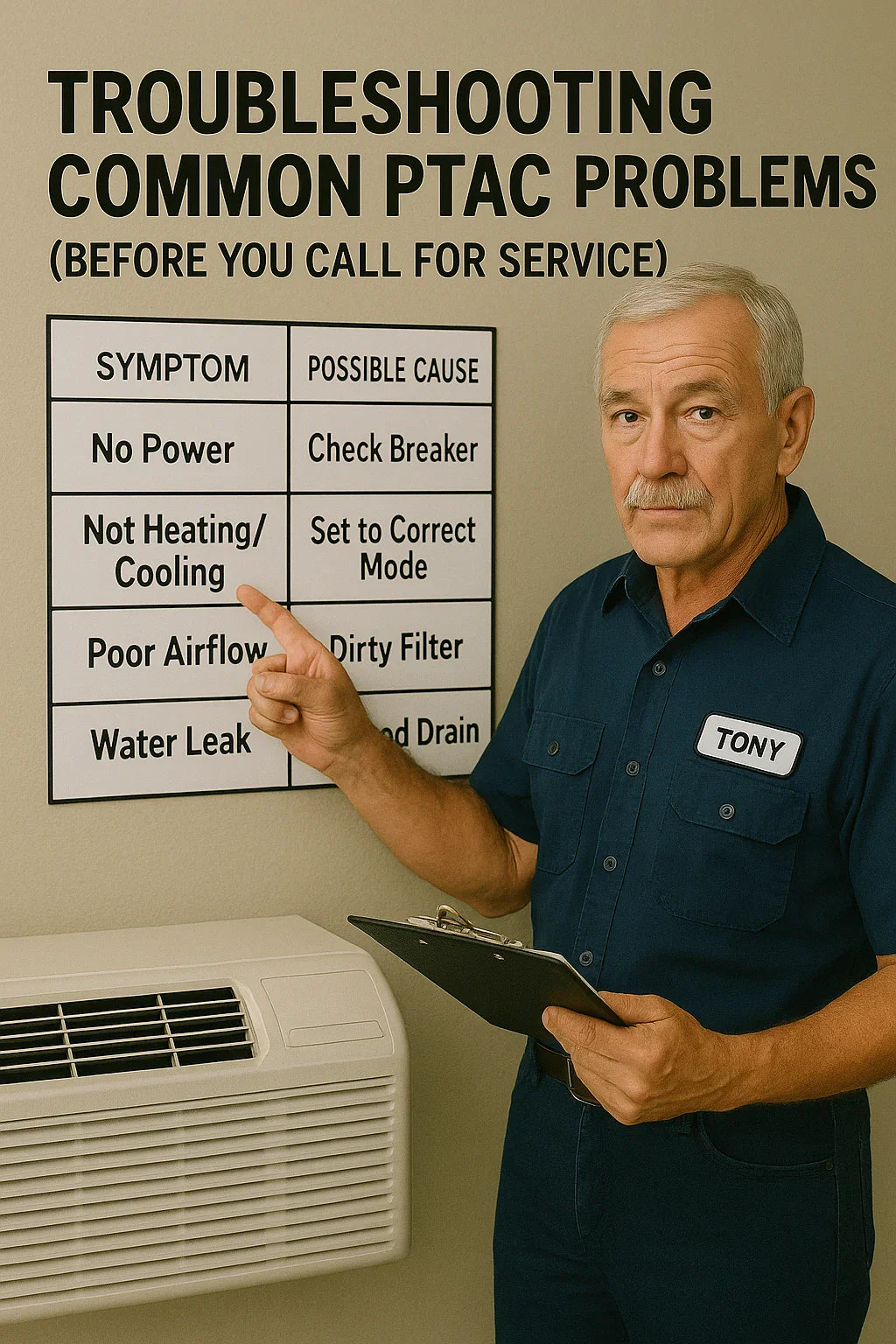

When a PTAC unit like the Amana Distinctions 12000 BTU PTAC with Heat Pump and Electric Backup starts acting up, your first instinct might be to call for professional service. But many common PTAC issues are easy to diagnose—and sometimes fix—before that expensive service call.

As Tony Marino, I’ll walk you through the most common PTAC problems, what likely causes them, and what steps you can take before picking up the phone.

❄️ PTAC Blowing Air But Not Cooling

Possible Causes:

-

Dirty filter restricting airflow

-

Clogged indoor coil (evaporator)

-

Low refrigerant charge (sealed system issue)

-

Faulty compressor or capacitor

-

Thermostat miscalibration

What You Can Check:

-

Clean or replace filter

-

Visually inspect indoor coil for dust buildup

-

Verify setpoint temperature is below room temp

-

Listen for compressor running noise (humming/vibrating)

👉 If compressor never starts: likely electrical (capacitor or compressor failure).

🔥 PTAC Won’t Heat Properly

Possible Causes:

-

Heat pump mode stuck (bad reversing valve)

-

Electric resistance heater failure

-

Limit switch tripped (safety shutoff)

-

Outdoor sensor malfunction

What You Can Check:

-

Verify outdoor temperature (below 35°F triggers backup heat)

-

Test both heat pump and electric backup modes

-

Reset unit by cycling power

-

Check for tripped breakers

💧 PTAC Leaking Water Indoors

Possible Causes:

-

Clogged condensate drain

-

Improper wall sleeve pitch (should slope outward)

-

Blocked exterior weep holes

-

Dirty indoor coil causing freeze-up

What You Can Check:

-

Inspect drain pan for standing water

-

Flush drain lines with mild bleach solution

-

Verify sleeve is properly pitched

-

Clean filters and coils to prevent icing

ASHRAE PTAC Drainage Guidelines

🔇 PTAC Making Excessive Noise

Possible Causes:

-

Loose front grille or mounting brackets

-

Off-balance blower wheel

-

Dirty fan blades

-

Worn motor bearings

-

Loose compressor mounts

What You Can Check:

-

Tighten front grille and cabinet screws

-

Inspect blower wheel for buildup or debris

-

Verify rear grille isn’t obstructed by leaves/debris

-

Use vibration-isolation pads if sleeve mounting is rigid

Amana PTAC Noise Troubleshooting Guide

⚡ PTAC Not Powering On

Possible Causes:

-

Tripped circuit breaker

-

Loose power cord plug (inside sleeve)

-

Control board failure

-

Burned wiring harness

What You Can Check:

-

Reset breaker and verify voltage at outlet

-

Inspect power plug connections

-

Look for burnt wire insulation

👉 Use caution—always disconnect power before opening electrical panels.

📟 PTAC Display Showing Error Codes

Amana PTACs often include self-diagnostic error codes.

| Code | Meaning |

|---|---|

| E1 | Room sensor failure |

| E2 | Outdoor sensor failure |

| E3 | Freeze protection active |

| E4 | Low refrigerant alert |

| E5 | Communication failure |

| L | Control board lockout |

What You Can Check:

-

Inspect and reconnect sensor wiring

-

Cycle power to clear minor lockouts

-

If repeated, call qualified tech

Amana PTAC Error Code Reference

🔎 Tony’s Quick PTAC Troubleshooting Checklist

1️⃣ Always start with the filter.

2️⃣ Verify thermostat setpoint and mode.

3️⃣ Inspect airflow obstructions front and rear.

4️⃣ Check condensate drainage.

5️⃣ Listen carefully for unusual noises.

6️⃣ Read error codes before power-cycling.

7️⃣ Document your findings for the tech (saves diagnosis time).

🚩 When You Definitely Need a Pro

✅ Refrigerant issues (sealed system work)

✅ Compressor or reversing valve failure

✅ Burnt wiring repairs

✅ Replacing control boards

✅ Persistent error codes after basic resets

✅ Tony’s Final Takeaway

A well-maintained Amana Distinctions PTAC is a workhorse, but even the best equipment hits occasional bumps.

Many PTAC issues can be addressed in-house with basic training and routine maintenance. Staying ahead of minor problems keeps your rooms comfortable, protects your investment, and avoids unnecessary downtime or costly emergency calls.

If in doubt, call your certified HVAC partner—but you’ll save time and money by ruling out the simple stuff first.

In the next topic we will know more about: Introduction: The HVAC Decision Many Building Owners Face