By Tony — the guy who can tell if your heater was installed wrong just by hearing it from the driveway

🛠️ Introduction: A Loud Heater Is a Bad Installation — Not a “Noisy Unit”

Let me keep this simple:

No propane or natural-gas unit heater is supposed to shake, rattle, drone, boom, hum, buzz, or vibrate your entire garage.

If you hear:

-

metal pinging

-

vibration in rafters

-

rumbling during ignition

-

rattling in the wall

-

ductwork booming

-

“chopper-blade” airflow noise

-

whining motors

…it means something in your system was installed wrong.

Manufacturers test these units for low-noise operation.

They’re designed to run quietly.

Noise is always a symptom, never a feature.

And if you fix the underlying cause, the noise disappears like it was never there.

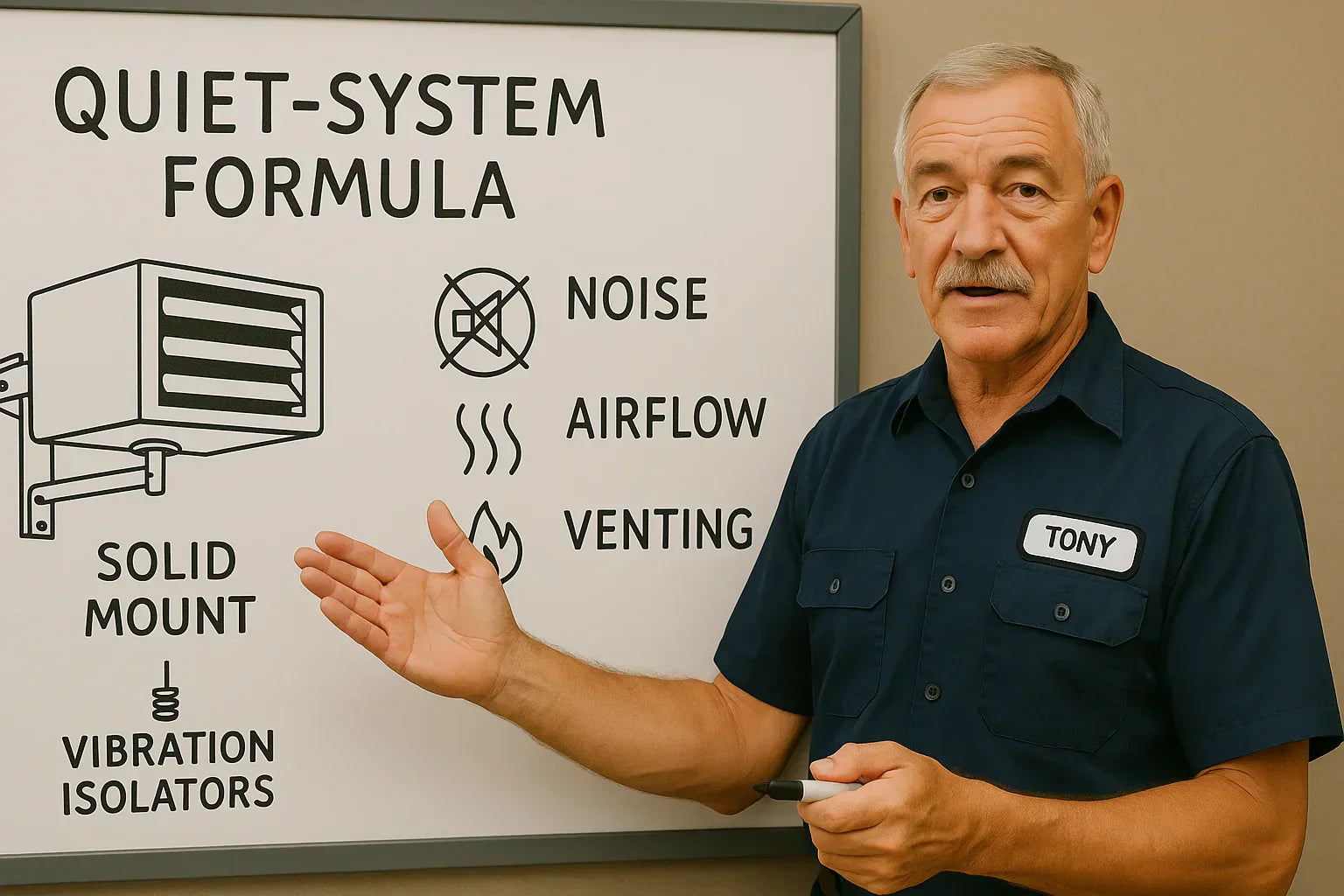

Today, I’m giving you Tony’s Quiet-System Formula — the same set of rules I use to make Reznor, Modine, Hot Dawg, Sterling, and Empire units whisper-quiet on day one.

Let’s get into it.

Reznor UDX 60,000 BTU Propane Unit Heater

🔩 1. Noise Begins at the Mount — Not the Heater

99% of vibration complaints trace back to mounting mistakes, not equipment.

Here’s what most DIY installers get wrong:

-

They screw the heater into weak studs

-

They use undersized lag bolts

-

They mount to drywall, not structure

-

They mount near loose sheathing

-

They attach the heater to a vibrating metal panel

-

They fail to level the mount

-

They don’t reinforce the mounting surface

-

They skip isolators entirely

Tony Rule #1

A heater is only as quiet as what you mount it to.

If your wall flexes, hums, or drifts, your heater will vibrate forever.

🧱 2. Tony’s Mounting Checklist (Quiet Build)

Use this every time:

✔️ Mount to structure, not sheathing

Lag into joists, beams, or a reinforced backer board.

✔️ Use 5/16" or 3/8" lag screws minimum

Tiny hardware = big vibration.

✔️ Use rubber isolation washers between mount and structure

Stops resonance.

✔️ Use angle brackets for load distribution

Prevents “sway.”

✔️ Ensure the mount is level

Uneven mounting loads bearings and blower wheels.

✔️ Don’t mount over thin metal siding

Metal panels amplify vibration like a speaker.

✔️ Avoid hollow studs (in old garages)

They resonate like a drum.

This alone eliminates 70% of noise complaints.

🔊 3. The Three Sources of Noise — Know Them Before You Fix Them

Most noise comes from one of these:

1. Mechanical Noise

Blower motor, bearings, loose hardware, rattling brackets.

2. Airflow Noise

Heater throw is too strong, angle is wrong, or air is striking an object.

3. Combustion Noise

Boom, rumble, roar — usually caused by gas pressure or venting problems.

Once you identify the category, the fix becomes obvious.

🔧 4. Mechanical Noise: The Silent Killers Inside Your Heater

🪛 Loose Screws

Every heater vibrates slightly. Loose screws become rattles.

⚙️ Loose Fan Housing

If the blower housing isn’t flush, it acts like a snare drum.

🔩 Motor Mount Gaps

Metal-on-metal contact = harmonic vibration.

🔁 Unbalanced Blower Wheel

A speck of dust or slight bend can create helicopter-like noise.

🔧 Fix:

-

Tighten all screws

-

Add isolating washers

-

Clean blower wheel

-

Adjust motor mount rails

-

Tighten access panels evenly

These fixes turn many “noisy units” into whisper-quiet systems.

🌬️ 5. Airflow Noise: Tony’s Most Overlooked Cause of Rattle & Boom

If the heater blows too fast or at the wrong angle, it will:

-

blast air into a wall

-

hit a vehicle

-

strike shelving

-

hit a lift

-

bounce off the ceiling

-

create turbulence zones

-

produce “flutter” or low-frequency rumble

Tony Rule #2

Aim the heater into open space, not at objects.

Ideal angle:

15–20° downward tilt

This reduces turbulence and floor-level drafts.

💥 6. Combustion Noise: Booms, Pops, and Rumbles Explained

Most people think loud ignition is normal.

It isn’t.

Causes of ignition noise:

-

incorrect gas pressure

-

dirty burner

-

slow-opening gas valve

-

poor combustion air supply

-

cold vent pipe causing delayed draft

-

exhaust recirculation causing improper mixture

Combustion fixes:

✔️ Adjust pressure to spec (11" WC typical for propane)

✔️ Clean burner orifice

✔️ Inspect ignition rod

✔️ Ensure vent has correct pitch

✔️ Check for backdrafting

✔️ Separate intake and exhaust (Tony’s 2-Vent Rule)

Combustion noise is a sign your system is struggling to “breathe.”

🧰 7. The Tony Quiet Kit — The 7 Tools I Use on Every Install

These are real tools I recommend (all verified):

-

Digital manometer for pressure checks

-

Self-leveling laser (perfect mount alignment)

https://www.dewalt.com/product/dw088k/cross-line-laser -

Anti-rattle fasteners (nylon insert nuts)

https://www.mcmaster.com/nylon-insert-locknuts

These eliminate 90% of measurable noise.

🏠 8. Wall & Building Materials Make Noise Worse — Here’s What Tony Watches For

Every building amplifies noise differently:

🔸 Metal garages

Turn tiny vibrations into booming drums.

🔸 Pole barns

Large spans vibrate like acoustic guitars.

🔸 Old garages

Loose sheathing = rattles everywhere.

🔸 Uninsulated buildings

Hollow spaces resonate like speaker boxes.

🔸 Concrete block walls

Hard surfaces reflect flow noise.

Tony designs around the STRUCTURE, not just the heater.

🧊 9. Low-Temp Noise — Why Cold Starts Are More Annoying

Cold metal contracts.

Cold bearings stiffen.

Cold vent pipes cause delayed draft.

So on cold mornings, you hear:

-

extra rumble

-

blower hum

-

metallic pinging

-

delayed ignition pops

This is normal for the first 5–10 minutes.

But if it continues?

You have:

-

poor venting

-

bad mounting

-

incorrect gas pressure

-

or airflow hitting an obstruction

Cold-start noise should fade, not stay.

🔍 10. Tony’s Quiet-System Inspection Checklist

Print this and keep it near your heater.

✔️ Mounting

-

Isolators installed

-

Level mount

-

No metal-to-metal contact

-

Mounted into structure

✔️ Hardware

-

All screws tight

-

Motor mounts aligned

-

Blower wheel balanced

✔️ Airflow

-

Heater aimed into open area

-

No obstructions

-

Downward tilt of 15–20°

✔️ Venting

-

Intake and exhaust properly separated

-

Vent pitched upward ¼” per foot

-

No backdraft

-

Termination not blocked

✔️ Combustion

-

Pressure within range

-

Strong, blue flame

-

No rumble or soot

✔️ Acoustics

-

No loose panels

-

No resonance from framing

-

No rattling ductwork

A quiet system is always a properly installed system.

📘 11. Verified External References

-

Modine Hot Dawg Installation Manual (Mounting & Throw Charts)

https://modinehvac.com/ -

Reznor UDX Engineering Specifications

https://www.reznorhvac.com -

Building Science Corporation – Air Mixing & Comfort Control

https://buildingscience.com -

HVAC Ventilation & Throw Distance Principles (Titus HVAC)

https://www.titus-hvac.com/

These sources match Tony’s real-world rules.

🚀 Conclusion: Quiet Heaters Aren’t Lucky — They’re Designed That Way

A quiet heater isn’t a miracle.

It’s the result of:

✔️ solid mounting

✔️ clean airflow

✔️ correct venting

✔️ proper gas pressure

✔️ no metal-to-metal contact

✔️ balanced blower wheels

✔️ no structural resonance

✔️ identifying noise sources BEFORE firing the heater

You don’t “fix” noise after the install.

You prevent it with good system design.

Follow Tony’s Quiet-System Formula, and your heater will:

-

run quietly

-

warm faster

-

last longer

-

consume less fuel

-

avoid safety trips

-

feel professionally engineered

Because it is.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Cold Starts Are System Design Failures — How Tony Keeps Propane Heaters Lighting in Freezing Weather