By Tony — the installer who’s fixed more “mysterious heater failures” than most companies have installs

🛠️ Introduction: One Rule That Saves More Heaters Than Any Wrench Ever Will

Most heater failures aren’t electrical.

They aren’t gas-related.

They aren’t ignition issues.

They aren’t brand problems.

They’re air problems.

And nothing causes more problems than installers ignoring the one rule that determines whether a heater breathes cleanly or suffocates:

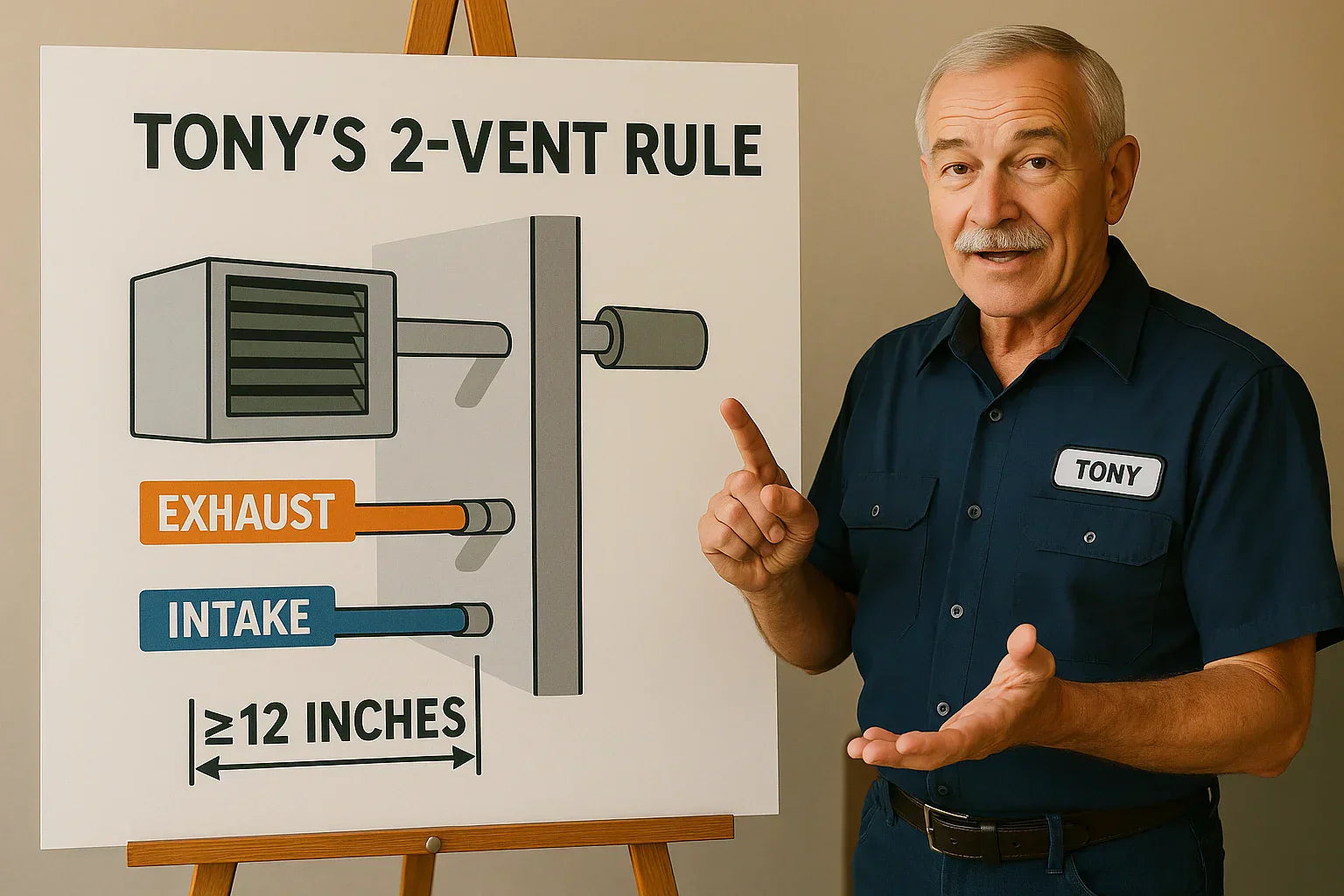

**Tony’s 2-Vent Rule:

Intake and exhaust must be separate —

unless the system is engineered as a sealed, balanced, direct-vent unit.**

If you cheat this rule, even a brand-new Reznor, Modine, Hot Dawg, or Sterling heater will:

-

burn dirty

-

backdraft

-

soot the heat exchanger

-

overheat

-

trigger pressure switches

-

shut down randomly

-

or fail within 1–5 years

This article breaks down exactly when the 2-vent rule applies, why it exists, what happens when it’s ignored, and how to design venting the right way every time.

Reznor UDX 60,000 BTU Propane Unit Heater

🌬️ 1. Why Heaters Need Two Separate Paths: One for Air Coming In, One for Air Going Out

A combustion appliance is like a human being:

You inhale.

You exhale.

You never try to do both through the same hole.

A propane or natural gas heater is the same.

It needs:

① Intake Vent

Brings in oxygen-rich air for combustion.

② Exhaust Vent

Removes combustion gases (CO₂, water vapor, trace CO) safely outdoors.

These two paths MUST be independent unless:

-

the heater is certified as sealed combustion,

-

factory-engineered to use a concentric vent,

-

and installed exactly as the manual specifies.

If you mix intake and exhaust, even slightly, you break every combustion law in the book.

🔥 2. What Happens When Intake and Exhaust Are Too Close (or Combined Wrong)

People try to cheat this rule constantly:

-

exhaust pipe 4" away from intake

-

intake pipe pointed toward exhaust path

-

two pipes exiting the same wall without spacing

-

intake pulled from a semi-enclosed porch

-

using a single oversized pipe for “shared flow” (total disaster)

-

concentric vent installed too close to soffit or corner

-

intake placed downwind of exhaust

Here’s what goes wrong:

❌ Backdrafting

Exhaust gets sucked back into the intake.

❌ Flame instability

Heater starves for oxygen.

❌ Soot formation

Dirty burn = shortened heat exchanger life.

❌ Condensation flooding the burner area

Propane exhaust is full of water vapor.

❌ CO production increases

Carbon monoxide spikes when oxygen declines.

❌ Pressure switch trips

Unit shuts off randomly, often labeled “faulty pressure switch.”

❌ Reduced BTU output

Dirty flame = less heat and higher fuel use.

❌ Ice buildup on winter exhaust-side walls

Steam condenses on siding instead of venting outward.

❌ Heater age is cut in half

A properly vented unit lasts 15–20 years.

A poorly vented one lasts 5–7 years, tops.

All because the installer ignored separation.

📏 3. Tony’s 2-Vent Rule — The Correct Separation Distances

This is my rule:

**Intake and exhaust must be separated by at least 12 inches horizontally

AND be oriented so exhaust can never re-enter the intake path.**

But here’s the real detail:

✔️ Minimum Separation

12" horizontal

24" vertical (intake always below exhaust)

✔️ Wind-Smart Orientation

Exhaust must not aim:

-

across the intake

-

toward a corner

-

into a dead air pocket

-

into a soffit

-

toward a deck

-

into a fenced enclosure

✔️ Flood & Snow Line Rule

Intake must be:

-

12" above grade minimum

-

24" above expected snow line

-

never located near roof runoff

✔️ High-Wind Zones

Double the separation in:

-

coastal zones

-

mountain valleys

-

open plains

✔️ Metal Buildings

Use extended vent kits to push exhaust beyond corrugated siding pockets.

This spacing prevents what kills most heaters: re-entrainment (exhaust being sucked back in).

🧊 4. Why Cold Weather Makes Improper Vent Placement 10× Worse

In winter, exhaust contains:

-

high moisture

-

warm vapor

-

low-density gases

As soon as that vapor hits cold air, it:

-

condenses

-

drops in density

-

curls downward

-

hugs walls

-

finds nearby openings

If your intake is even remotely close,

bam — backdraft.

This is why homeowners often say:

“My heater only has problems when it’s really cold.”

Cold amplifies every venting mistake.

🔧 5. The Only Time You Don’t Need Two Separate Pipes: Factory-Engineered Concentric Venting

Direct-vent units sometimes allow a concentric vent:

-

Exhaust flows through the center pipe

-

Intake air flows through the surrounding outer pipe

-

The two are completely separated internally

But here’s the part DIYers miss:

✔️ the concentric vent must be UL-listed

✔️ you MUST use the manufacturer’s kit

✔️ you cannot substitute HVAC pipe

✔️ it must be mounted with correct pitch

✔️ it must terminate in open air with no obstructions

✔️ it must be installed in the exact orientation shown

Most failures occur because someone tries to “save money” by building a makeshift concentric vent from hardware-store parts.

That absolutely WILL cause recirculation.

🏗️ 6. When You Must Separate Intake and Exhaust — No Exceptions

Here are the situations where the two vents must be fully independent:

✔️ Non-sealed combustion heaters

(every natural-draft and most power-vent models)

✔️ Any heater installed in a tight garage or workshop

(compression sealing makes backdraft more likely)

✔️ Spray-foamed buildings

(super airtight, any recirculation becomes dangerous)

✔️ Metal buildings

(corrugations trap exhaust and recirculate it)

✔️ Rooms with negative pressure sources:

-

exhaust fans

-

tumble dryers

-

paint booths

-

dust collectors

-

bath fans

-

attic fans

Negative pressure sucks exhaust straight into intake if vents are too close.

✔️ When the heater pulls combustion air from outdoors

(aka true 2-pipe direct vent)

✔️ When code requires separate vent paths (most states)

If ANY of these apply, the intake and exhaust cannot be anywhere near each other.

🧪 7. Real-World Examples From Tony’s Job Log

Case 1: The 60,000 BTU Reznor That Wouldn’t Stay Lit

Vents 4" apart

Cold morning = vapor cloud re-entrainment

Fix: Separate by 18" and turn exhaust 45° away

Result: Perfect operation

Case 2: Metal Building Shop — Heavy Sooting

Exhaust venting into a corrugated pocket

Intake directly below

Fix: 24" separation + extended vent

Result: Blue flame, 20°F faster warm-up

Case 3: Garage With Spray Foam

Heater kept tripping pressure switch

Why? Zero natural infiltration

Fix: Separate vents + fresh air intake

Result: No cycling problems at all

Case 4: “Bad Heater” Returned to Store

Not bad — installed with intake facing exhaust plume

Fix: reorient vent

Result: Customer apologized to heater

🔍 8. How to Inspect Your Own Intake & Exhaust (Tony’s Checklist)

✔️ Step 1 — Measure separation

Are they 12" horizontally and 24" vertically apart?

If not, reposition.

✔️ Step 2 — Watch exhaust on a cold morning

If exhaust vapor curls toward the intake, you have recirculation.

✔️ Step 3 — Check wall pockets

Brick, stone, and metal siding trap exhaust.

✔️ Step 4 — Look for discoloration

Soot near the intake = serious problem.

✔️ Step 5 — Feel the intake temperature

If warm or damp, you're sucking in exhaust.

✔️ Step 6 — Check pitch of exhaust pipe

Must pitch upward 1/4" per foot.

✔️ Step 7 — Confirm fresh air supply

If the heater uses indoor air, that air must be replaced.

This checklist solves 80% of all “strange heater problems.”

📘 9. Verified External Sources Supporting the 2-Vent Rule (Up to 6)

These are reputable, code-based sources that match Tony’s rules:

-

Modine Hot Dawg Installation Manual (Mounting & Throw Charts)

https://modinehvac.com/ -

Reznor UDX Engineering Specifications

https://www.reznorhvac.com -

Building Science Corporation – Air Mixing & Comfort Control

https://buildingscience.com -

HVAC Ventilation & Throw Distance Principles (Titus HVAC)

https://www.titus-hvac.com/

All confirm the same truth:

Backdrafting and recirculation destroy heaters and risk CO exposure — vent separation stops it.

🚀 Conclusion: You Can’t Cheat Physics — Intake and Exhaust Must Be Independent

If you want your heater to:

✔️ burn clean

✔️ last 15–20 years

✔️ stay efficient

✔️ avoid soot buildup

✔️ avoid flame rollouts

✔️ avoid pressure switch trips

✔️ avoid condensation damage

✔️ avoid CO risks

…then follow Tony’s 2-Vent Rule without exceptions.

When the intake and exhaust are separated correctly, the heater breathes clean air, expels waste properly, and performs EXACTLY as designed.

When they’re too close?

You’re fighting physics with aluminum elbows and hope.

And physics always wins.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Why Your Heater Short-Cycles — The Thermostat Placement Mistakes Nobody Talks About