🧰 Through-the-Wall Heat Pump Installation Guide: What Jake Learned Doing It Himself

Persona: Jake – A hands-on, measure-twice-cut-once kind of guy who likes saving money with DIY, but knows where to draw the line before a job turns into a disaster.

☕ Introduction — Why I Decided to Install It Myself

I’ve always been the kind of homeowner who looks at a project and thinks, “I can do that”. Sometimes that works out beautifully (like my kitchen backsplash), and sometimes… well, let’s just say there’s a reason my deck rail is now on version three.

When my old window AC and electric space heater were guzzling electricity and barely keeping my home office comfortable, I started shopping for a through-the-wall heat pump. They’re sleek, efficient, and work year-round. The only catch? Installation can cost $500–$1,000+ if you hire a pro.

That was enough for me to start researching a DIY install. I learned a ton—and I’ll share the step-by-step process, rookie mistakes to avoid, and exactly when to call in a professional.

Best Through The Wall Heat Pumps

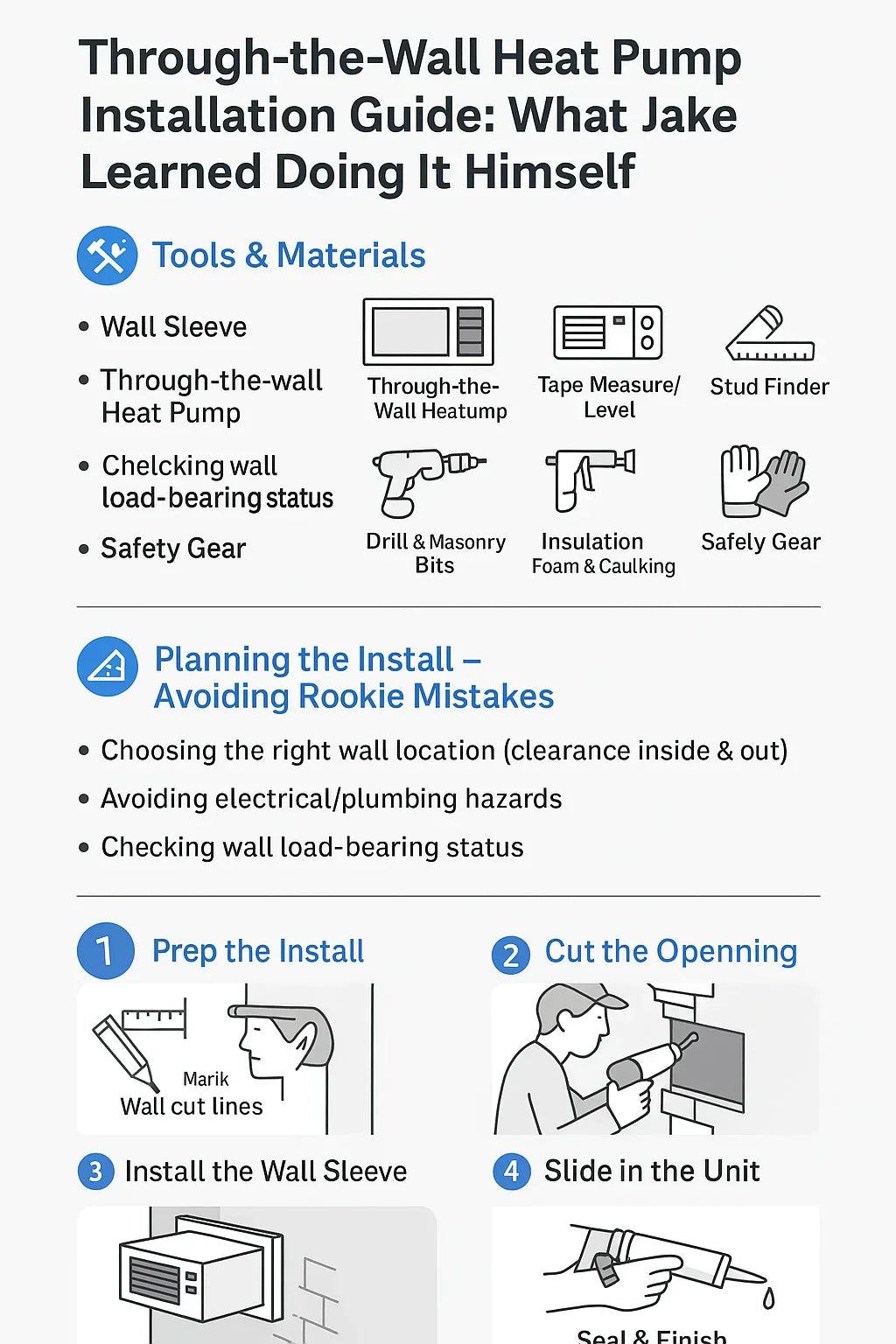

🛠 Tools & Materials Checklist

Before you start, make sure you’ve got the right gear on hand. Nothing kills momentum faster than having to run to the hardware store halfway through.

Basic Tools:

-

Tape measure

-

Level

-

Stud finder

-

Reciprocating saw (or circular saw with masonry blade for brick walls)

-

Drill with assorted bits (masonry bits if brick)

-

Screwdrivers (Phillips and flathead)

-

Utility knife

Materials:

-

Wall sleeve (specific to your heat pump model)

-

Through-the-wall heat pump unit

-

Insulation foam sealant

-

Exterior-grade caulk

-

Trim kit (optional, for a clean finish)

-

Flashing (for weatherproofing exterior)

Safety Gear:

-

Safety goggles

-

Heavy-duty gloves

-

Dust mask or respirator

-

Ear protection

Resource: If you’re not sure about a particular tool, check out this installation tool guide from Family Handyman (FamilyHandyman.com).

📏 Planning the Install — Avoiding Rookie Mistakes

The prep stage is where most DIY installs either get set up for success or head straight toward frustration.

1. Choosing the Right Location

-

Pick an exterior-facing wall with clear access both inside and outside.

-

Avoid walls where furniture or drapes could block airflow.

-

Check clearance requirements—most manufacturers specify a minimum outdoor clearance for airflow.

Reference: ENERGY STAR’s clearance guidance (EnergyStar.gov).

2. Checking for Hazards

-

Use a stud finder to locate wall studs.

-

Watch for electrical wiring—cutting into that is a shocking experience you don’t want.

-

Look for plumbing lines—especially if you’re working on a shared wall near a bathroom or kitchen.

3. Confirming the Wall Type

-

Wood framing: Easier to cut and frame.

-

Brick or concrete: Requires masonry blades and more patience.

-

Load-bearing wall: Still possible, but you may need to add extra framing.

🧰 Step-by-Step Installation Process

This is the exact process I followed, with notes on where I slowed down and double-checked my work.

Step 1: Prep the Wall Opening 📐

-

Measure your wall sleeve dimensions twice—most are slightly larger than the unit itself.

-

Mark your cutout on the wall using a level to ensure it’s perfectly square.

-

Use painter’s tape to outline the cut—this helps prevent chipping or splintering.

Step 2: Cut the Opening 🔪

-

For drywall: Use a utility knife to score first, then a reciprocating saw for the through-cuts.

-

For exterior siding or brick: Drill pilot holes in each corner and use a reciprocating saw with the appropriate blade (or an angle grinder for brick).

Tip from Jake: If you’re cutting masonry, go slow and wear a respirator—dust is no joke.

Reference: Cutting tips from This Old House (ThisOldHouse.com).

Step 3: Install the Wall Sleeve 🧱

-

Slide the sleeve into the opening from the inside.

-

Make sure it’s pitched slightly downward toward the outside for proper drainage.

-

Secure the sleeve to the framing using screws.

-

Fill any gaps between the sleeve and wall with spray foam insulation.

Note: The wall sleeve is not optional—it protects the unit and ensures a snug, weatherproof fit.

Step 4: Slide in the Unit 📦

-

Most through-the-wall units weigh between 70–120 lbs—grab a helper.

-

Align the unit’s tracks with the sleeve and slide it in slowly.

-

Ensure it’s seated fully, with no gaps.

Step 5: Connect Power ⚡

-

Check your model’s voltage requirement—common options are 115V or 230V.

-

Plug into a dedicated outlet.

-

If a dedicated circuit is required, or if wiring is needed, this is pro territory.

Reference: Electrical safety per the National Electrical Code (NFPA.org).

Step 6: Seal & Finish 🧼

-

Apply exterior-grade caulk around the sleeve outside.

-

Install any provided flashing to direct rainwater away.

-

Use the trim kit inside for a clean finish.

⚠ Common DIY Installation Mistakes to Avoid

-

Forgetting the drainage pitch — water backs up into your wall.

-

Cutting too large — you’ll have gaps to fill and possible air leaks.

-

Skipping insulation around the sleeve — invites drafts and reduces efficiency.

-

Not checking electrical capacity — can blow breakers or damage your unit.

Resource: Troubleshooting installation errors from HVAC.com (HVAC.com).

✅ Testing the Unit — Jake’s “First Run” Checklist

-

Turn it on in cooling mode—check airflow and temp drop.

-

Switch to heating mode—listen for smooth operation.

-

Check condensate drainage outside.

-

Inspect for any unusual noises or vibrations.

📞 When to Call a Pro

Even the most confident DIYers need backup sometimes.

Call a licensed installer if:

-

You discover structural issues (load-bearing wall complications).

-

Electrical upgrades are needed (new circuit, voltage changes).

-

You find plumbing or hidden wiring.

-

You’re working in masonry and don’t have the right tools.

Reference: Find vetted contractors on Angi (Angi.com).

💬 Jake’s Final Thoughts — Was DIY Worth It?

For me, yes—but only because I took my time, had the right tools, and wasn’t afraid to stop and research when I hit something new.

Total savings: About $700 in labor.

Total time: Roughly 5 hours split over two days.

Would I do it again? Absolutely, but I’d still hire an electrician for the wiring part if I didn’t already have the right outlet in place.

If you’re the type to rush, skip instructions, or hope for the best with power tools—hire a pro. If you’re methodical and patient, this is a totally doable weekend project.

External References in This Guide:

In the Next Topic we will know more about: Best Wall Sleeve Options for Heat Pumps: Compatibility, Fit & Noise Reduction