As the HVAC industry accelerates its shift toward eco-conscious refrigerants, A2L refrigerants are taking center stage. Their low global warming potential (GWP) makes them a sustainable alternative to high-GWP legacy refrigerants, but adopting A2Ls introduces new technical and safety challenges—especially when selecting expansion valves, which directly affect system performance, efficiency, and operational safety.

This guide explores the critical factors in choosing the right expansion valves for A2L systems—balancing thermodynamic performance, material compatibility, regulatory compliance, and long-term reliability.

Understanding A2L Refrigerants: Properties and Applications

A2L refrigerants, such as R-32, R-454B, and R-1234yf, are classified as mildly flammable and low-GWP under ASHRAE Standard 34. They strike a balance between environmental responsibility and thermodynamic performance.

Key Properties:

-

Low GWP: Significantly less climate impact than HFCs like R-410A.

-

Mild Flammability: Requires specific precautions during system design and operation.

-

High Efficiency: Favorable pressure and enthalpy profiles improve system output.

Applications:

-

Residential and commercial air conditioning

-

Heat pumps

-

Supermarket refrigeration

-

Light industrial cooling systems

As regulations phase down HFCs, understanding how A2L refrigerants behave in real-world conditions is essential for designing safe, efficient systems.

The Role of Expansion Valves in Refrigeration Systems

Expansion valves control refrigerant flow into the evaporator, regulating pressure and ensuring efficient heat absorption.

Systems like the Goodman 2 Ton R32 Condenser require expansion valves that handle variable thermal loads with safe, consistent flow regulation.

Why They Matter:

-

Control Superheat: Prevents liquid refrigerant from reaching the compressor.

-

Match System Load: Adapts refrigerant flow to varying thermal demands.

-

Affect Efficiency: Directly influences energy use, cycle stability, and cooling performance.

In A2L-based systems, the expansion valve must also accommodate the refrigerant's unique flammability and thermodynamic profile—making valve choice more critical than ever.

Learn how the right valve helps your entire system adapt to A2L properties in “A2L vs. HFCs: Is Your HVAC System Fueling the Future—or Holding It Back?

Key Considerations When Selecting Expansion Valves for A2L Refrigerants

1. Refrigerant Compatibility

-

Must handle A2L refrigerant pressure/temperature ranges.

-

Materials and lubricants should resist degradation or reactivity.

2. Valve Sizing

-

Undersized valves = poor cooling performance, high superheat.

-

Oversized valves = flooding risk, inefficient operation.

-

Match to actual load profile and refrigerant flow rates for stability.

3. Material Durability

-

Use A2L-compatible elastomers, stainless steel, or brass.

-

Confirm chemical resistance of internal seals and gaskets to prevent leakage or corrosion.

4. Safety and Certifications

-

Ensure valves are approved for use with flammable refrigerants.

-

Follow UL, IEC, and ASHRAE guidelines for A2L-rated components.

A well-chosen expansion valve supports precise control, safe operation, and long-term system health.

For larger loads, consider pairing with a 3 Ton R32 Scroll Condenser designed for efficient operation under variable capacity.

Types of Expansion Valves: Pros and Cons

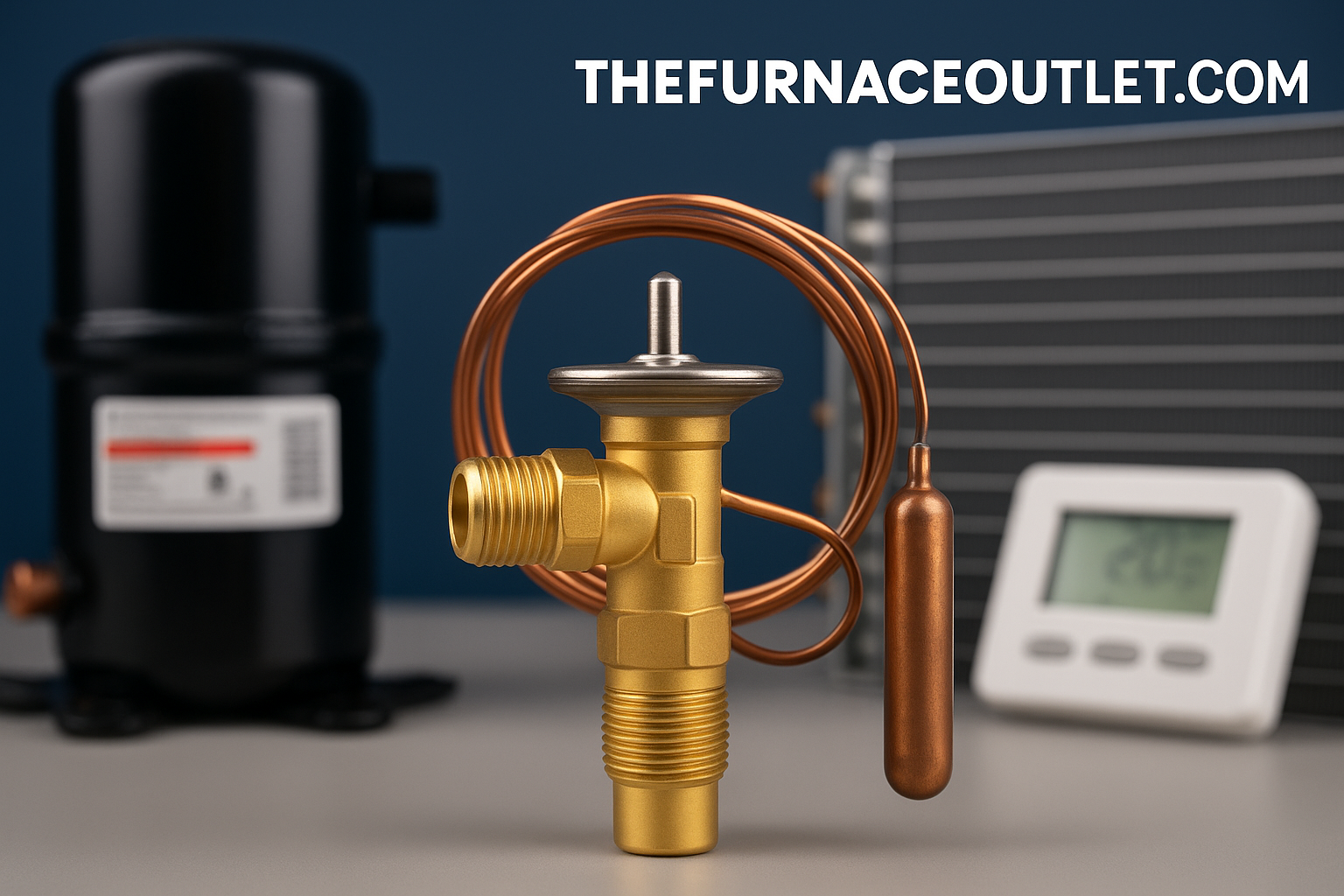

1. Thermostatic Expansion Valves (TXVs)

-

Pros: Simple, reliable, self-regulating superheat.

-

Cons: Limited precision; slower to respond to load changes; sensitive to bulb placement and calibration.

2. Electronic Expansion Valves (EEVs)

-

Pros: High accuracy, fast response, optimal energy efficiency under varying loads.

-

Cons: Higher cost; requires electronic control system and skilled commissioning.

3. Automatic Expansion Valves (AXVs)

-

Pros: Cost-effective; suitable for stable load environments.

-

Cons: Not ideal for variable load systems; limited efficiency and control.

EEVs are increasingly favored in A2L systems due to their precision and ability to adapt to fluctuating conditions, especially in commercial and variable-capacity applications.

Material Compatibility with A2L Refrigerants

The mild flammability and chemical structure of A2Ls make material compatibility a non-negotiable factor.

Metals:

-

Stainless steel and brass are preferred.

-

Avoid alloys susceptible to stress corrosion cracking in A2L environments.

Elastomers:

-

Must resist chemical degradation and temperature extremes.

-

EPDM, HNBR, and Teflon (PTFE) are generally suitable—verified with manufacturers.

Plastics and Coatings:

-

Used in actuators and sensors—must be validated for long-term exposure.

Material failure in valves can lead to refrigerant leaks, pressure drops, or ignition risks.

Explore evaporator design tips to ensure all connected components—including valves—can withstand A2L exposure.

Efficiency Impacts of Expansion Valve Selection

Correct expansion valve selection contributes to:

-

Stable superheat control

-

Fewer compressor trips

-

Lower energy use

-

Improved load-following performance

Inaccurate sizing or poor control can cause:

-

Compressor overheating

-

Flooded evaporators

-

Short cycling

-

Increased wear on system components

EEVs can help achieve 10–20% better system efficiency in variable load conditions compared to traditional TXVs.

Maximize control and efficiency in large systems with the 5 Ton R32 High-Efficiency Condenser, optimized for performance with precision valves.

Safety Standards and Regulatory Compliance

When working with A2L refrigerants, you must comply with:

ASHRAE Standard 15

-

Sets limits on refrigerant charge sizes.

-

Requires leak detection, ventilation, and safe component selection.

IEC 60335-2-40

-

Governs electrical safety in HVAC equipment using flammable refrigerants.

UL and Local Codes

-

Ensure all components, including valves, meet A2L flammability risk classifications.

Proper documentation, labeling, and technician training are essential for both safety and legal compliance.

Common Challenges and Practical Solutions

|

Challenge |

Solution |

|

Valve material degradation |

Choose A2L-certified valves with verified material ratings |

|

Improper sizing due to refrigerant switch |

Recalculate flow and capacity using A2L-specific properties |

|

Safety risks during retrofits |

Install leak detection and follow charge size limitations |

|

Inconsistent superheat control |

Upgrade to EEVs with real-time sensors and controls |

A retrofit-ready 4 Ton R32 Outdoor Condenser is ideal for modern systems requiring upgraded A2L-rated valves.

Best Practices for Installation and Maintenance

Installation Tips:

-

Use clean, dry lines and avoid contamination.

-

Position sensing bulbs (TXVs) correctly for accurate temperature feedback.

-

Ensure adequate access for maintenance and inspection.

Maintenance Best Practices:

-

Inspect for corrosion or leaks regularly.

-

Calibrate or update EEV firmware if applicable.

-

Record and track superheat readings over time.

Proactive maintenance helps preserve valve functionality and extends system life—especially in A2L environments where small issues can have safety implications.

Making the Right Choice for A2L Systems

Choosing the right expansion valve for A2L refrigerants is more than a technical decision—it’s a commitment to system integrity, energy efficiency, and occupant safety.

Ensure your refrigeration or HVAC system delivers sustainable, efficient, and safe performance in line with future-ready standards.

Browse R32-compatible AC units to match your expansion valve strategy and build for long-term safety, compliance, and performance.