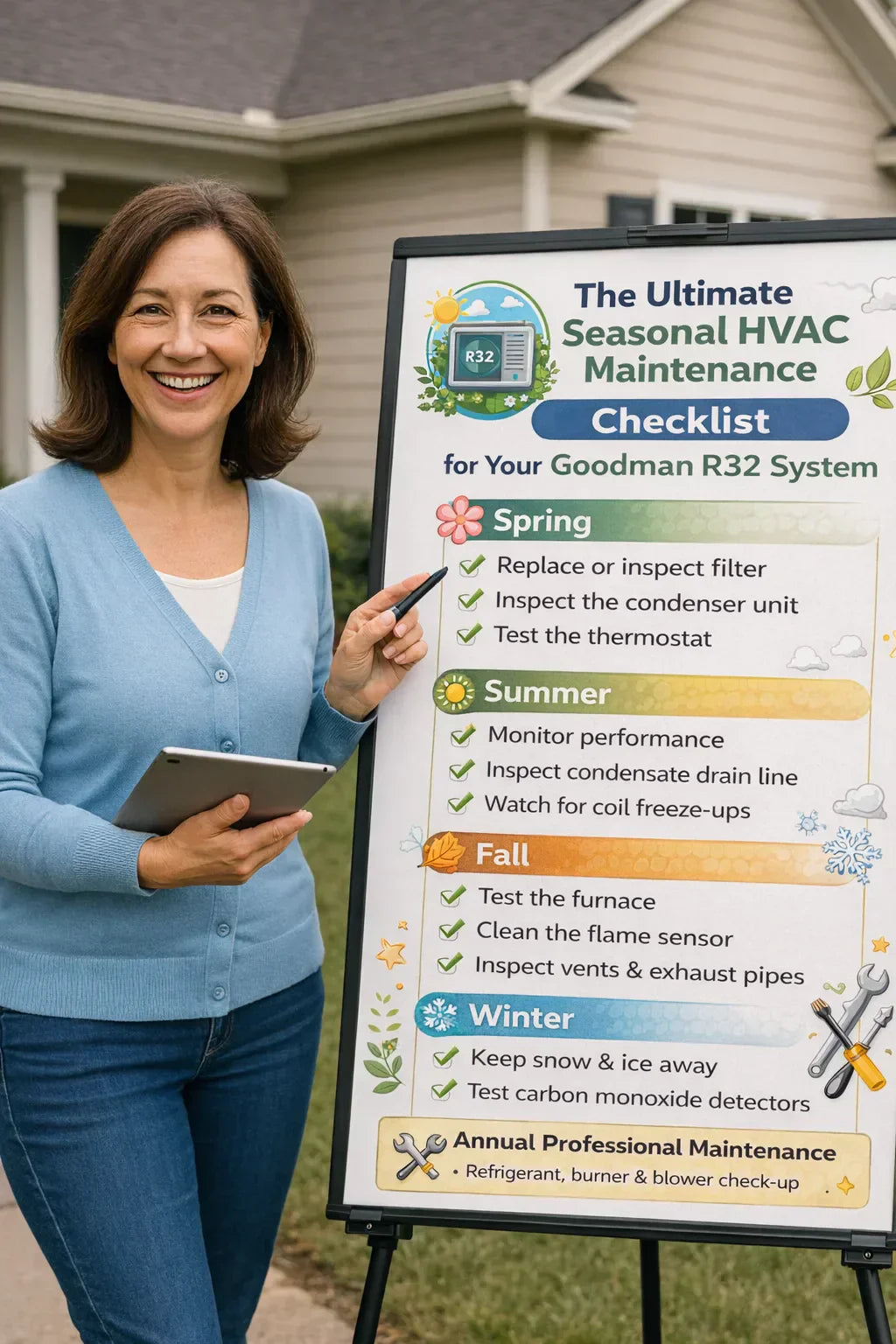

How to protect efficiency, comfort, and longevity—one season at a time

Owning a Goodman R-32 HVAC system means you’ve already made a smart move toward better efficiency, lower environmental impact, and dependable performance. But here’s the part many homeowners overlook: even the best system can’t protect itself.

Seasonal maintenance isn’t about being obsessive—it’s about being intentional. Each season puts a different kind of stress on your system, and knowing what to check and when can be the difference between smooth operation and a mid-season breakdown.

In this guide, I’ll walk you through a season-by-season HVAC maintenance checklist designed specifically for Goodman R-32 air conditioners and gas furnaces—with clear DIY steps, safety notes, and cues for when it’s time to call a pro.

Goodman 3.5 Ton 15.2 SEER2 System: R32 Air Conditioner Condenser model GLXS4BA4210,

Let’s keep your system running like it should—quiet, efficient, and reliable.

🌸 Spring Maintenance Checklist (Cooling Prep Season)

Spring is your golden window for HVAC maintenance. The weather is mild, technicians aren’t booked solid yet, and small issues are easier to catch before summer demand hits.

✅ Replace or Inspect the Air Filter

A clean filter is the foundation of system health.

-

Replace disposable filters or wash reusable ones

-

Check airflow direction arrows

-

Ensure a snug fit—no gaps around the edges

👉 Dirty filters reduce airflow, strain the blower motor, and can lead to frozen evaporator coils.

Helpful reference:

Energy Star – Air Filter Maintenance

https://www.energystar.gov/saveathome/heating-cooling/maintenance-checklist

🌀 Inspect the Outdoor Condenser Unit

Your outdoor unit has been sitting idle all winter—and collecting debris.

-

Remove leaves, sticks, and dirt

-

Trim vegetation at least 24 inches around the unit

-

Check for bent fins or visible damage

⚠️ Never use a pressure washer—gentle hose spray only.

🔌 Check Electrical Connections (Visual Only)

You’re not tightening wires here—just looking.

-

Inspect disconnect box for corrosion

-

Look for frayed insulation or loose conduit

-

Listen for buzzing sounds when running

If anything looks or sounds off, that’s your cue to stop and call a technician.

🌡️ Test the Thermostat

Before cooling season starts in earnest:

-

Switch to cooling mode

-

Verify accurate temperature readings

-

Replace thermostat batteries if applicable

Pro tip: Programmable or smart thermostats help reduce runtime during peak hours.

Helpful reference:

U.S. Department of Energy – Thermostat Settings

https://www.energy.gov/energysaver/programmable-thermostats

☀️ Summer Maintenance Checklist (Peak Performance Mode)

Summer is when your Goodman R-32 system works the hardest. Maintenance here is about keeping stress low and efficiency high.

❄️ Monitor System Performance Weekly

Pay attention to how your system behaves:

-

Longer-than-usual run times

-

Uneven cooling between rooms

-

Warm air from vents

These are early warning signs—don’t ignore them.

💧 Inspect the Condensate Drain Line

High humidity means more condensation.

-

Look for water pooling near the indoor unit

-

Clear drain line with vinegar or approved cleaner

-

Ensure drain pan isn’t cracked or rusted

Clogged drains can shut your system down unexpectedly.

Helpful reference:

EPA – Indoor Humidity Control

https://www.epa.gov/indoor-air-quality-iaq

🧊 Watch for Coil Freeze-Ups

Ice on refrigerant lines or the indoor coil usually means:

-

Restricted airflow

-

Dirty filter

-

Blocked vents

Turn the system off immediately if you see ice and let it thaw before restarting.

🔊 Listen for Unusual Noises

Rattling, grinding, or buzzing isn’t “normal summer noise.”

-

Rattling → loose panels or debris

-

Buzzing → electrical issues

-

Grinding → motor bearings

Catching noise early can prevent catastrophic failures.

🍂 Fall Maintenance Checklist (Heating Prep Season)

Fall is your second major maintenance window—and it’s just as important as spring.

🔥 Test the Furnace Before Cold Weather Hits

Don’t wait for the first freezing night.

-

Switch thermostat to heat

-

Listen for smooth ignition

-

Check for burning dust smell (normal initially)

If the system short-cycles or fails to ignite, stop and schedule service.

🧼 Clean or Inspect the Flame Sensor

A dirty flame sensor is one of the most common furnace failure points.

-

Causes ignition failure

-

Often fixable with gentle cleaning

-

Usually best handled by a technician

Helpful reference:

Flame Sensor Basics

🌬️ Inspect Venting & Exhaust Pipes

For gas furnaces, venting is non-negotiable.

-

Look for loose connections

-

Check for corrosion or blockages

-

Ensure outdoor exhaust is clear of debris

Improper venting can lead to carbon monoxide risks.

🔁 Replace the Air Filter (Yes, Again)

Heating season moves a lot of air—and dust.

-

Replace filters before winter

-

Use consistent replacement intervals

-

Mark the date on the filter frame

❄️ Winter Maintenance Checklist (Safety & Stability)

Winter maintenance is about monitoring, not deep cleaning.

🛑 Keep Snow & Ice Away from Outdoor Components

If your system includes an outdoor unit:

-

Clear snow buildup after storms

-

Avoid ice accumulation near the base

-

Never chip ice with tools

🧯 Test Carbon Monoxide Detectors

This is not optional.

-

Test monthly during heating season

-

Replace batteries annually

-

Install near sleeping areas

Helpful reference:

CDC – Carbon Monoxide Safety

https://www.cdc.gov/carbon-monoxide/about/index.html

👀 Watch for Short Cycling

Short cycling stresses components and increases fuel usage.

Possible causes include:

-

Dirty filters

-

Thermostat placement issues

-

Oversized equipment

If short cycling persists, schedule a professional evaluation.

🧰 Annual Professional Maintenance (When to Call the Pros)

Even the best DIY checklist doesn’t replace a trained technician.

✔️ What a Pro Tune-Up Covers

-

Refrigerant pressure verification (R-32 specific)

-

Combustion analysis for gas furnaces

-

Electrical load testing

-

Blower motor inspection

-

Safety control verification

Helpful reference:

ENERGY STAR – HVAC Maintenance

https://www.energystar.gov/saveathome/heating-cooling/maintenance-checklist

🗓️ Simple Yearly Maintenance Schedule

| Season | Key Focus |

|---|---|

| Spring | Cooling prep & airflow |

| Summer | Performance monitoring |

| Fall | Heating safety & ignition |

| Winter | CO safety & reliability |

🌱 Why Seasonal Maintenance Matters More with R-32 Systems

R-32 refrigerant is:

-

More efficient

-

Lower global warming potential

-

Slightly higher pressure than R-410A

That means proper airflow and clean components matter even more to protect efficiency and system lifespan.

Helpful reference:

ASHRAE – Refrigerant Safety Overview

https://www.ashrae.org/technical-resources/standards-and-guidelines/ashrae-refrigerant-designations

✅ Final Thoughts from Samantha

Your Goodman R-32 system doesn’t need constant attention—but it does need consistent care.

Seasonal maintenance:

-

Lowers energy bills

-

Reduces surprise breakdowns

-

Protects warranties

-

Extends system lifespan

Think of this checklist as a rhythm, not a chore. Follow it year after year, and your system will quietly reward you with comfort you don’t have to think about.

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: Air Filters 101: How MERV Ratings Impact Your Home’s Air Quality and HVAC Health