If your Reznor propane unit heater fires up every winter and you forget about it until something goes wrong, you’re playing an expensive game of chance.

These heaters are built tough, but they’re not maintenance-free. Dust, vibration, propane combustion byproducts, and seasonal temperature swings all take a toll. The good news? A structured annual maintenance routine can easily add years of service life, improve fuel efficiency, and help you avoid mid-winter breakdowns.

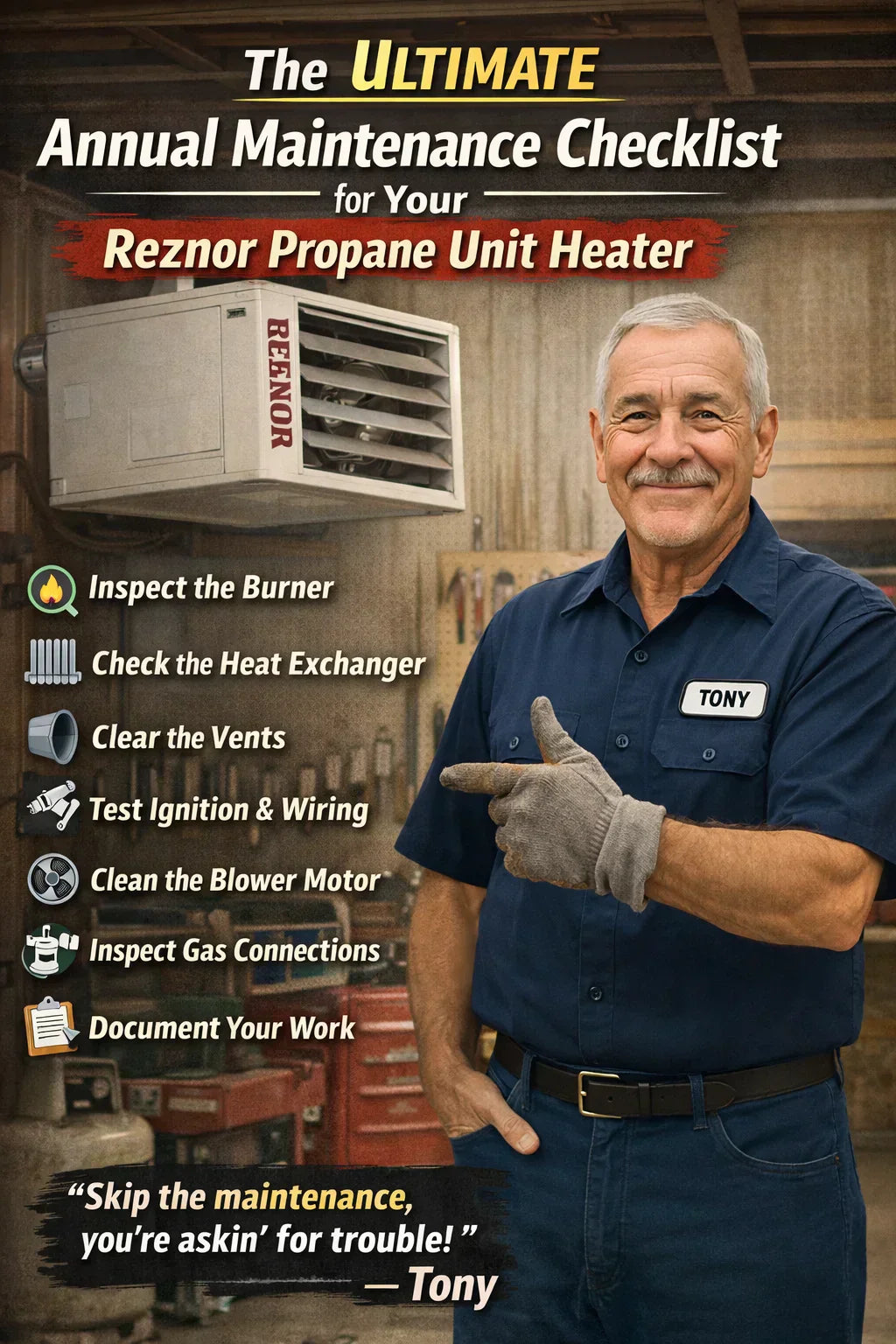

Reznor UDX 60,000 BTU Propane Unit Heater

This guide walks you through exactly what to check, clean, test, and tighten—once a year—with notes on what you can handle yourself and where calling a pro makes sense.

🧭 Before You Start: Safety First (Non-Negotiable)

Before touching anything:

-

Turn OFF power at the disconnect

-

Shut OFF propane supply

-

Let the unit cool completely

-

Use gloves, eye protection, and a stable ladder

-

Never bypass safety switches or gas controls

If you smell gas at any point, stop immediately and ventilate the space.

🗓️ Your Annual Maintenance Timeline (At a Glance)

Once per year (ideal timing: early fall):

-

Full inspection & cleaning

-

Electrical and ignition checks

-

Burner and heat exchanger inspection

-

Venting and combustion air verification

During heating season (monthly quick check):

-

Visual flame check

-

Listen for unusual noises

-

Confirm airflow and temperature rise

Now let’s break down the annual checklist step by step.

🔍 Step 1: Exterior & Mounting Inspection

Start with what you can see.

Check for:

-

Loose mounting hardware or brackets

-

Rust, corrosion, or cracked panels

-

Signs of vibration damage

-

Oil, dust, or debris buildup on housing

Why this matters:

Reznor heaters vibrate during operation. Over time, even solid installs can loosen, leading to noise, airflow issues, or structural stress.

Action:

Tighten mounting bolts, clean exterior surfaces, and note any corrosion early before it spreads.

🔥 Step 2: Burner Assembly & Flame Inspection

This is where heat is made—and where efficiency is often lost.

What to inspect:

-

Burner tubes for dust, rust flakes, or spider webs

-

Orifice openings for blockage

-

Flame color during operation (after re-startup)

Healthy flame =

-

Mostly blue

-

Stable and even

-

No lifting or yellow tips

Yellow or lazy flames usually mean:

-

Dirty burners

-

Improper air/fuel mix

-

Restricted combustion air

Action:

Remove burners carefully and clean with a soft brush and compressed air. Never enlarge or drill orifices.

🔗 Reference combustion guidance:

https://www.energystar.gov/products/furnaces

🧯 Step 3: Heat Exchanger Inspection (Critical)

The heat exchanger separates combustion gases from the air you breathe. If it fails, carbon monoxide risk increases.

Inspect for:

-

Cracks or splits

-

Rust scaling

-

Soot buildup

-

Discoloration from overheating

How to check:

-

Use a flashlight and mirror

-

Look from both burner and blower sides

-

Check seams and bends carefully

Action:

Light surface dust can be vacuumed. Cracks or corrosion = stop using the heater and call a pro immediately.

🔗 Heat exchanger safety info:

https://www.cpsc.gov/Safety-Education/Safety-Education-Centers/Carbon-Monoxide-Information-Center

🌬️ Step 4: Venting & Combustion Air System

Propane heaters must breathe properly.

Inspect:

-

Vent pipe connections and slope

-

Signs of corrosion or separation

-

Exhaust termination outside (clear of snow, nests, debris)

-

Combustion air intake openings

Common problems:

-

Blocked vents causing shutdowns

-

Backdrafting

-

Moisture corrosion in horizontal runs

Action:

Clear obstructions, reseal joints if needed, and verify venting meets manufacturer clearances.

🔗 Venting best practices:

https://www.nfpa.org/education-and-research/home-fire-safety/heating

⚡ Step 5: Electrical & Ignition Components

Modern Reznor units rely on clean electrical signals.

Inspect and clean:

-

Igniter (no cracks, secure mounting)

-

Flame sensor (lightly clean with fine abrasive pad)

-

Wiring connections (tight, no burnt insulation)

-

Control board mounting (no moisture or dust buildup)

Why this matters:

Most “no-heat” calls trace back to dirty flame sensors or loose connections—not failed boards.

Action:

Clean, tighten, and re-secure. Replace damaged wiring immediately.

🌀 Step 6: Blower Motor & Fan Assembly

Airflow equals heat delivery.

Check for:

-

Dust buildup on fan blades

-

Wobble or imbalance

-

Motor bearing noise

-

Set screw tightness

Action:

-

Vacuum or brush blades clean

-

Tighten set screws

-

Lubricate motor bearings only if the motor design allows

Warning:

Over-lubrication can kill motors. If it’s a sealed motor, do not oil it.

🔗 General motor maintenance guidance:

https://www.energy.gov/energysaver/home-heating-systems

📏 Step 7: Gas Supply & Connections

Propane systems demand respect.

Inspect:

-

Gas line fittings for leaks (soap bubble test)

-

Flexible connectors for cracking

-

Regulator condition

-

Sediment traps (if installed)

Action:

Any bubbling, corrosion, or damage = shut down and repair before operation.

🔗 Propane safety basics:

https://propane.com/propane-safety-in-your-home/

🌡️ Step 8: Airflow, Filters & Temperature Rise

Restricted airflow shortens heater life.

Check:

-

Air intake screens

-

Discharge louvers

-

Any external filters or screens (if used)

Then test temperature rise:

-

Measure supply air temp

-

Measure return/ambient air temp

-

Compare to Reznor’s rated temperature rise range

Action:

If temps are too high, airflow is likely restricted.

🔄 Step 9: Startup Test & Operational Check

Once everything is reassembled:

-

Restore gas and power

-

Call for heat

-

Observe full ignition cycle

-

Listen for abnormal sounds

-

Verify proper shutdown

You want:

-

Smooth ignition

-

Even airflow

-

No rattles, bangs, or delayed ignition

🧾 Step 10: Document What You Did

This step separates pros from amateurs.

Log:

-

Date of service

-

Parts cleaned or replaced

-

Flame appearance

-

Any concerns to monitor

Why this matters:

Patterns reveal problems early—and documentation helps with warranty or resale.

🔗 Reznor product documentation reference:

https://www.reznorhvac.com

🧠 When to Call a Professional

Call an HVAC pro if you find:

-

Heat exchanger damage

-

Repeated ignition failures

-

Gas pressure issues

-

Control board faults

-

CO detector alarms

Annual DIY maintenance is smart. Ignoring safety thresholds is not.

🏁 Final Word from Tony

A Reznor propane unit heater is a workhorse—but even workhorses need care.

One focused afternoon of annual maintenance can:

-

Cut fuel waste

-

Prevent mid-winter failures

-

Extend equipment life

-

Keep your shop safe and comfortable

Do the checklist. Log the results. Fix small problems early.

That’s how you keep heat reliable when it matters most.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: How to Tune Up the Burner and Flame Assembly on Your Reznor Heater