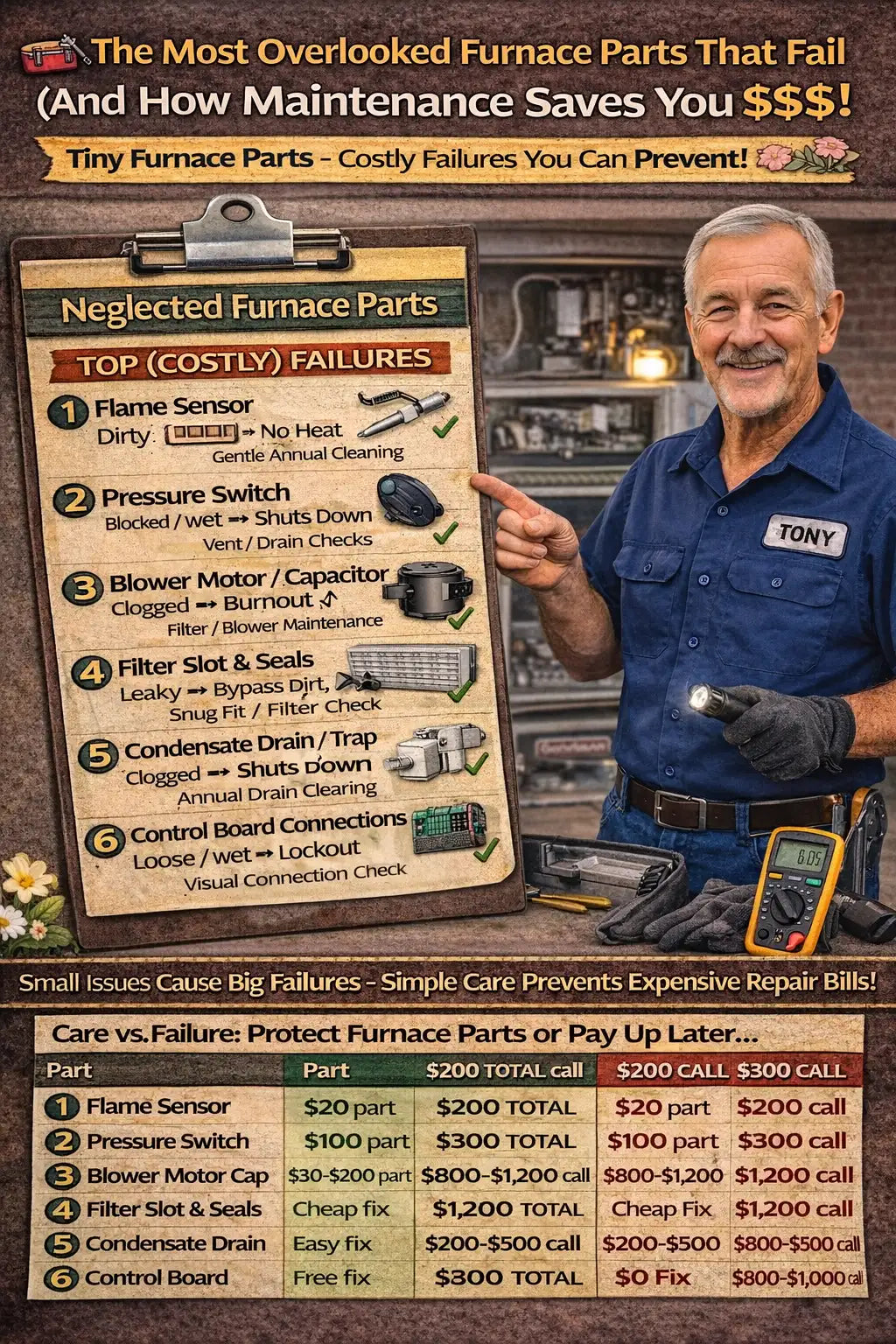

The small components that cause big breakdowns—and what simple upkeep prevents

When a furnace fails, homeowners usually assume the worst: “The furnace is shot.”

Most of the time, that’s not true.

In reality, furnaces rarely die all at once. They fail because small, inexpensive parts are ignored, overworked, or never maintained—and those failures cascade into bigger, costlier problems.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

This guide walks through the most commonly overlooked furnace parts, why they fail, and how basic maintenance can save you hundreds—or thousands—of dollars over the life of your system.

This is exactly how I explain it to homeowners standing next to a “dead” furnace.

🧠 Why Small Furnace Parts Matter So Much

Modern furnaces are full of safety systems. That’s a good thing—but it also means:

-

One failed part can shut the entire system down

-

Many failures are preventative shutdowns, not catastrophic damage

-

Maintenance often fixes the cause before the breakdown

According to the U.S. Department of Energy, neglected maintenance is one of the leading causes of HVAC system failure and energy waste.

🔗 https://www.energy.gov/energysaver/home-heating-systems

Let’s talk about the parts that quietly fail first.

🔥 Flame Sensor: The $20 Part That Stops Everything

What It Does

The flame sensor confirms that burners are lit safely. If it doesn’t “see” flame, the furnace shuts off gas immediately.

Why It Fails

-

Carbon buildup

-

Oxidation

-

Lack of annual cleaning

What Happens When It Fails

-

Furnace starts, then shuts off

-

Repeated ignition attempts

-

No heat in cold weather

How Maintenance Saves You

-

Gentle annual cleaning

-

Keeping airflow clean (filters matter)

This part costs little—but causes many emergency calls.

🌬️ Pressure Switch: The Safety Gatekeeper

What It Does

Confirms proper airflow and venting before ignition.

Why It Fails

-

Blocked intake/exhaust pipes

-

Condensate buildup

-

Dust or moisture in tubing

Symptoms

-

Furnace won’t start

-

Error codes related to airflow

-

Short cycling

Maintenance Fix

-

Keep vent pipes clear

-

Check condensate drains

-

Inspect tubing visually

The EPA confirms blocked venting is a common cause of combustion appliance shutdowns.

https://www.epa.gov/indoor-air-quality-iaq/what-are-combustion-products

🌀 Blower Motor & Capacitor: Silent Workhorses

What They Do

The blower motor moves heated air through your home. The capacitor helps it start and run efficiently.

Why They Fail

-

Dirty blower wheels

-

Restricted airflow from clogged filters

-

Overheating due to neglect

Warning Signs

-

Weak airflow

-

Loud humming or grinding

-

Furnace overheating or shutting down

Maintenance Payoff

-

Clean blower wheel

-

Regular filter replacement

-

Prevents motor burnout

Replacing a capacitor is cheap. Replacing a motor is not.

🧼 Furnace Filter Slot & Seals: Small Gaps, Big Problems

What They Do

Ensure all air passes through the filter—not around it.

Why They Fail

-

Wrong filter size

-

Bent filter racks

-

Missing seals

Result

-

Dirt bypasses the filter

-

Blower wheel contamination

-

Heat exchanger stress

ASHRAE confirms bypass air reduces filtration effectiveness and increases equipment wear.

🔗 https://www.ashrae.org/technical-resources

Maintenance here costs almost nothing—but protects expensive components.

💧 Condensate Drain & Trap (High-Efficiency Furnaces)

What It Does

Safely removes condensation created during combustion.

Why It Fails

-

Algae growth

-

Debris buildup

-

Frozen or cracked lines

Symptoms

-

Furnace shuts down unexpectedly

-

Water around the base

-

Pressure switch faults

Maintenance Solution

-

Inspect drain annually

-

Keep lines clear

-

Prevent moisture damage

The EPA warns that unmanaged HVAC moisture leads to corrosion and system damage.

https://www.epa.gov/indoor-air-quality-iaq/moisture-control-guidance-building-design-construction-and-maintenance-0

⚡ Ignitor: Fragile but Critical

What It Does

Lights the burners safely.

Why It Fails

-

Dust buildup

-

Handling during DIY work

-

Voltage stress from frequent cycling

Failure Symptoms

-

Clicking without ignition

-

Error codes

-

No flame

Maintenance Helps By

-

Keeping furnace interior clean

-

Preventing short cycling

-

Avoiding unnecessary handling

Ignitors are delicate—maintenance reduces stress on them.

🔌 Control Board Connections: Loose = Locked Out

What They Do

Coordinate all furnace operations.

Why They Fail

-

Vibration over time

-

Moisture exposure

-

Rodent damage

Signs

-

Random shutdowns

-

Inconsistent operation

-

Hard-to-diagnose faults

Maintenance Prevention

-

Visual inspection

-

Pest prevention

-

Dry, clean furnace area

The Consumer Product Safety Commission highlights wiring damage as a common household hazard.

🔥 Heat Exchanger Supports & Seals (Often Ignored)

What They Do

Maintain alignment and safety of the heat exchanger.

Why They Fail

-

Overheating from airflow restriction

-

Corrosion from moisture

-

Long-term neglect

Risk

-

Cracks

-

CO exposure

-

Furnace replacement

Maintenance that protects airflow also protects the heat exchanger.

💰 Real Cost Comparison: Maintenance vs. Failure

| Part Neglected | Typical Cost | Preventable? |

|---|---|---|

| Flame sensor | $150–$300 service call | ✅ |

| Capacitor | $200–$400 | ✅ |

| Blower motor | $800–$1,500 | ✅ |

| Control board | $600–$1,200 | ⚠️ |

| Heat exchanger | Furnace replacement | ❌ |

Most big failures start with a small one.

🧾 Tony’s Real-World Rule

Here’s how I keep furnaces running long-term:

-

Maintain airflow first

-

Keep moisture under control

-

Clean, don’t “adjust”

-

Fix small issues early

Furnaces don’t fail suddenly—they warn you quietly.

🏁 Final Word from Tony

The most expensive furnace failures usually start with the cheapest parts.

Maintenance isn’t about perfection—it’s about paying attention. Clean filters, clear airflow, dry components, and early inspections prevent the majority of breakdowns I see every winter.

Spend a little time now, or a lot of money later.

That’s not sales talk—that’s experience.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: How to Maintain Furnace Airflow for Better Comfort & Efficiency