How Jake Designs Mechanical Rooms That Let 96% AFUE Furnaces Breathe, Run Quietly & Hit Their True Efficiency Rating

📘 Introduction: When a Furnace Is Too Big for the Room

You’d think that installing a high-efficiency furnace is as simple as “put the new one where the old one was.”

Jake disagrees.

Because when you upgrade a 20-year-old 80% furnace with a modern 96% AFUE, wide-body cabinet like the Goodman GR9T96, you discover the hidden enemy:

The room itself becomes the airflow restriction.

Modern furnaces—especially 21-inch cabinets—require:

-

more return air

-

more transition space

-

more filter surface area

-

more clearance around the cabinet

-

more thoughtful duct geometry

-

more service space for ECM motors, drains, PVC venting, and coil boxes

Most homes don’t have this.

The result?

-

noisy blower

-

cold rooms

-

overheating furnace

-

poor temperature rise

-

collapsed or choked return

-

Stage 2 engaging too often

-

clogged 1-inch filter cartridge

-

damaged ECM motor

-

efficiency drop from 96% to ~82–85% in real conditions

Jake calls this the 21-Inch Cabinet Problem — when the furnace cabinet width exceeds the available geometry of the mechanical room.

And in this guide, he fixes it.

🧱 1. What Exactly Is the 21-Inch Cabinet Problem?

A. Old furnaces were skinny. New ones are not.

Most 20–30-year-old furnaces were:

-

17.5" wide

-

single-stage

-

PSC motors

-

low airflow requirements

-

minimal filter surface area

Modern high-efficiency furnaces like the Goodman GR9T96 are:

-

21 inches wide

-

deeper

-

heavier

-

two-stage

-

ECM blower-driven

-

needing low-static airflow

That extra 3.5 inches is where the chaos starts.

B. Existing rooms weren’t built for modern geometry

Most utility closets and basement furnace rooms were framed to:

-

fit the old furnace

-

fit old return box dimensions

-

fit a thin 1" filter

-

leave the minimum clearance for service

Not the 21-inch cabinet that needs:

-

space for a media filter

-

space for a coil box

-

space for a full-size return drop

-

space for a wide plenum

-

space for PVC venting

C. Mechanical rooms are shrinking

Builders today reduce square footage in places homeowners “won’t notice,” including:

-

utility closets

-

basement utility corners

-

hallway furnace alcoves

-

upstairs laundry-mechanical combos

The furnace didn't shrink.

The room did.

D. The consequences of the 21-inch cabinet problem

Jake sees:

-

furnace pushed flush against a wall

-

return box smashed into framing

-

filter rack inaccessible

-

coil box crushed into floor joists

-

PVC venting kinked or flattened

-

condensate traps jammed into walls

-

high static pressure

-

loud airflow

-

overheating

-

comfort imbalance

This leads to system failure unless the room layout is redesigned.

🏠 2. Jake’s Rule #1: A Furnace Room Is Not a Box — It’s an Airflow Chamber

Most installers treat the room as storage space. Jake treats it as a duct fitting.

Jake explains it like this:

“The furnace room is part of the duct system. If it’s small, the system chokes.

If it’s shaped wrong, airflow goes turbulent.”

He redesigns furnace rooms with airflow behavior in mind:

-

turbulence reduction

-

smooth return air approach

-

proper transition angles

-

clear filter access

-

enough space for coil-to-plenum geometry

-

clean service space

-

combustion air flow

A furnace room must:

-

allow the blower to intake air smoothly

-

allow the filter to be inserted flat, not bent

-

allow the return air to enter uniformly

-

allow space for the coil and supply transitions

-

allow access for cleaning and maintenance

When it doesn’t, the system suffers.

🧯 3. Required Clearances for a 96% AFUE Furnace

A. Manufacturer minimum clearances

Goodman requires typical minimums of:

-

24–30 inches front clearance

-

1–3 inches on the sides

-

6 inches above the furnace

-

adequate space for venting + condensate

These are minimums for legality, not efficiency.

B. Jake’s real-world clearance standards

Jake adds:

-

40 inches front access for ECM blower and filter

-

6–10 inches side access on return side

-

12 inches above coil for plenum transition

-

18 inches for PVC vent routing

-

8–12 inches behind for piping clearance

This isn’t wasted space.

This is airflow-sustaining space.

C. Why tight rooms kill ECM blowers

ECMs adjust speed based on resistance.

If the room physically restricts the filter and return air:

-

ECM ramps up

-

static pressure increases

-

airflow decreases

-

noise skyrockets

-

motor overheats

-

lifespan drops dramatically

Jake warns:

“A tight furnace room is more dangerous to an ECM motor than dirty ducts.”

🔄 4. The Airflow Choke Points: How Tight Rooms Destroy Performance

Jake identifies four choke points in 90% of 21-inch cabinet installs.

A. Choke #1 — The Return Drop Pinch

Most return drops are:

-

tucked between wall and furnace

-

10" or 12" width

-

transitional

-

undersized for ECM CFM

When a 21" cabinet is flush against one wall:

-

return drop can only be on the other side

-

return box becomes shallower

-

filter rack becomes unusable

-

return air gets sucked unevenly

-

static pressure skyrockets

Jake sees static rise from 0.45" to 1.10" simply due to return pinch.

B. Choke #2 — The Filter Rack Trap

In tight rooms:

-

4-inch media filters don’t fit

-

racks must be removed to insert filters

-

filters get bent or compressed

-

gaps create bypass airflow

The filter becomes:

“A folded sheet of cardboard the blower is fighting against.”

C. Choke #3 — The Coil-on-Top Squeeze

Coils need stable airflow.

When coil boxes are squeezed against joists or framing:

-

plenum cannot be properly formed

-

coil drain pan airflow suffers

-

refrigerant performance drops

-

air leaks around coil box joints increase

A 21-inch cabinet + coil = at least 45 inches of vertical space needed.

Many homes offer 30–38.

D. Choke #4 — The Supply Transition Dead Stop

Supply trunk often hits:

-

a basement beam

-

staircase stringer

-

low floor joists

-

plumbing

-

existing trunks

This forces:

-

sharp 90° bends

-

flat transitions

-

undersized trunk

-

airflow turbulence

Jake calls this:

“The airflow dead stop.”

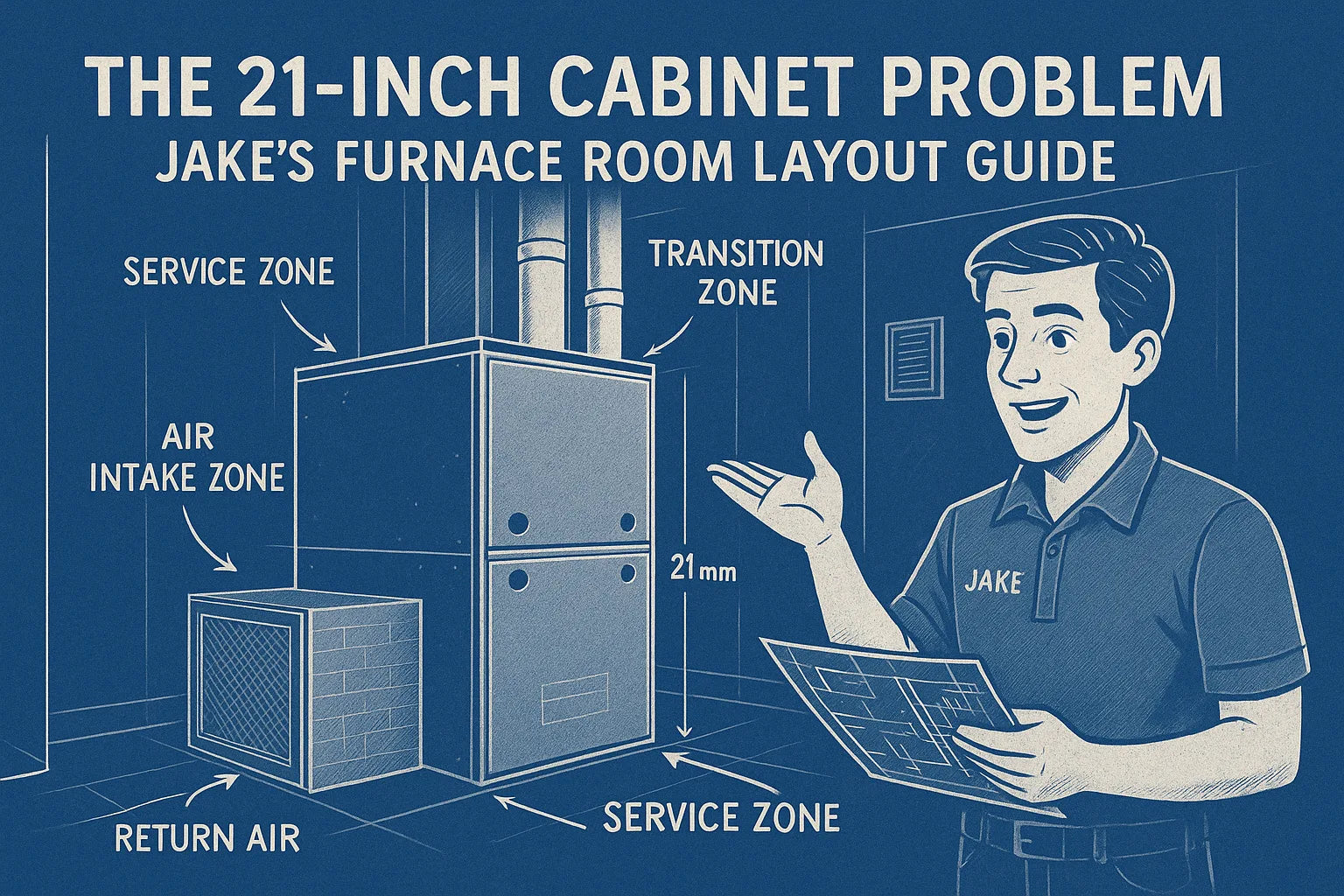

🧭 5. Jake’s Furnace Room Geometry: The 3-Zone Layout Method

Jake divides every mechanical room into three airflow zones:

ZONE 1 — SERVICE ZONE (Front)

This zone must allow:

-

blower removal

-

ECM access

-

control board access

-

filter replacement

-

combustion inspection

-

gas valve access

Jake requires 40 inches minimum.

ZONE 2 — AIR INTAKE ZONE (Sides, Under Cabinet)

Return air enters from:

-

return drop

-

side grills

-

under-cabinet floor return (some installs)

This requires:

-

6–10 inches on return side

-

unrestricted floor intake

-

smooth airflow approach

ZONE 3 — TRANSITION ZONE (Top + Coil Area)

This zone handles:

-

coil box

-

supply plenum

-

PVC vent

-

humidifier

-

duct transitions

Jake requires:

-

10–18 inches above the coil

-

no framing pressure

-

room for radius elbows

🔁 6. Designing the Return Air System in Tight Rooms

Jake’s return design rules:

A. Side returns are almost always wrong on a 21-inch cabinet

Side returns require:

-

12–16 inches of side clearance

-

space for filter rack

-

smooth box transitions

Most closets only give 1–3 inches.

So Jake says:

“Side return on a 21-inch cabinet is a trap unless the room is massive.”

B. Jake’s bottom-return platform method

When space is tight, Jake shifts to bottom return:

Benefits:

-

wide surface area

-

low static pressure

-

full use of cabinet width

-

easier filter rack design

-

cleaner airflow approach

Jake builds:

-

a plenum-style return box

-

a raised furnace platform

-

smooth 45° transitions

Bottom return = zero-choke airflow.

C. Closet installs demand enormous return grille area

Jake’s standard:

2 sq in of grille free area per CFM

A GR9T96 needs 1,200–1,400 CFM in high fire:

So:

1,400 × 2 = 2,800 sq in of grille free area

That’s:

-

four 20x30 returns, or

-

two huge louvered doors

Most homes have one 8x16.

Hence, the choking.

🧾 7. The Filter Access Problem No Installer Talks About

In tight rooms:

-

the filter must bend to remove

-

the rack hits the wall

-

access door can’t open

-

homeowners don’t replace filters

-

filters crush or deform

This boosts static pressure by:

0.20” to 0.40” instantly

Jake solves it by:

-

moving furnace forward

-

moving furnace sideways

-

adding access panels

-

relocating return

-

converting to bottom return

-

installing side-access media boxes

He chooses the method that protects:

-

ECM motor

-

heat exchanger

-

temperature rise integrity

-

return duct integrity

📦 8. Supply Plenum + Coil Layout for Zero-Choke Installs

The GR9T96 is 21 inches wide, so the coil box is:

-

also 21 inches

-

plus insulation

-

plus drain pan

-

plus plenum transition

This requires:

-

deep mechanical rooms

-

full coil clearance

-

non-restrictive top transitions

Jake prefers:

-

angled plenums

-

offset transitions only when necessary

-

long 45° transitions on horizontal installs

-

keeping coil centered in airflow stream

🚪 9. Mechanical Room Doors: The Secret Airflow Restrictor

Jake sees this all the time:

-

builders install a solid door

-

furnace sucks return air from cracks

-

door vibrates

-

metal whistles

-

furnace short-cycles

Jake fixes it by:

-

using louvered doors

-

adding return grilles

-

relieving pressure in the closet

-

adding jump ducts

-

adding passive return pathways

A sealed door is death for a 21-inch furnace cabinet in a tight room.

🧊 10. Venting & Condensate in Tight Rooms

96% AFUE furnaces have:

-

PVC venting

-

condensate traps

-

drain lines

-

inducer fans

-

trap assemblies

In tight rooms:

-

PVC bends too tight

-

condensate lines pinch

-

drain slope is incorrect

-

trap sits against wall

-

freezing risk increases

Jake solves it with:

-

wall-mounted trap stands

-

insulated PVC

-

extended clearances

-

parallel drain routing

This ensures:

-

no freezing

-

no gurgling

-

no trap backup

🛠️ 11. Jake’s No-Choke Checklist for 21-Inch Cabinets

Jake’s mechanical room checklist:

-

✔️ 40" front clearance

-

✔️ 6–10" return side clearance

-

✔️ bottom return platform for tight rooms

-

✔️ 4" media filter access

-

✔️ coil box clearance above furnace

-

✔️ smooth plenum transitions

-

✔️ PVC vent clearance

-

✔️ drain line slope

-

✔️ no solid-door suction

-

✔️ jump ducts for pressure relief

-

✔️ return grille free area sized correctly

A furnace room built around this list never chokes.

🧪 12. Case Study: Fixing a Choked 21-Inch Install

Home:

2,400 sq ft two-story

Furnace: Goodman GR9T96

Room: Basement closet

Symptoms:

-

loud airflow

-

3°F temperature imbalance

-

high-limit trips

-

filter bending during removal

Jake’s fix:

-

moved furnace 6 inches forward

-

converted to bottom return

-

upgraded to 4" media filter

-

rebuilt coil transition

-

added double return grilles in closet door

Results:

-

Static pressure: 0.96" → 0.46"

-

Noise: 70% reduction

-

Temp imbalance: fixed

-

Stage 1 now runs 80% of time

-

Furnace efficiency increased

🔗 13. Verified External References

🎯 Conclusion: The Room IS the System

A 96% AFUE furnace is not just a box that heats air. It’s a high-performance airflow machine.

If the furnace room is:

-

too tight

-

too narrow

-

too shallow

-

too blocked

-

too restrictive

then your furnace is suffocating.

Jake’s goal is simple:

“Give the furnace room the geometry it needs and the furnace will reward you with comfort, silence, and real efficiency.”

This is the blueprint for making 21-inch cabinets work in any home—without choking the system.

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic we will know more about: Jake’s Smart Thermostat Compatibility Map: Which Controls Actually Unlock Two-Stage Performance