By Samantha Reyes — Smart Shopper, Comfort Optimizer, and “Why Is My System So Loud?” Detective.

A modern HVAC system isn’t just a metal box that blows air—it’s a finely tuned pressure machine. And at the heart of that machine is your blower motor.

Specifically, your ECM motor.

ECM motors are the new standard in high-efficiency systems, including most Goodman, Amana, Daikin, Trane, and Lennox equipment. Manufacturers promote them as “smart,” “self-adjusting,” and “energy-saving.”

All of that is true.

But there’s a big hidden problem homeowners don’t know:

ECM motors will sacrifice themselves trying to compensate for bad static pressure.

They’ll ramp up, pull more wattage, fight duct restrictions, and run hotter—all to meet airflow targets your system should be able to deliver but can’t because of poor duct design.

This article walks you through what I call Static-Pressure Architecture—the framework I personally use to design home HVAC systems that keep ECM motors running efficiently, quietly, and for decades.

Goodman 3.5 Ton 15.2 SEER2 System

Let’s start with the basics.

📘 1. What Static Pressure Actually Is (Simple Explanation)

Most homeowners have heard their HVAC tech say:

-

“Your static pressure is too high.”

-

“Your blower’s working too hard.”

-

“Your ducts are restricting airflow.”

But what does that mean?

📌 Static pressure = air resistance inside your HVAC system.

Think of it like cholesterol in a bloodstream:

-

The blower = the heart

-

The ducts = arteries

-

Airflow = blood

-

Static pressure = plaque buildup

More restriction → more pressure → more strain → faster failure.

📍 Ideal static pressure target

For modern ECM blower motors, the recommended total external static pressure (TESP) is:

0.3–0.5 inches of water column (in. w.c.)

Most homes I’ve tested are 0.8–1.2 in. w.c.

That’s 2–4× higher than recommended.

According to ACCA (Manual D), that level of pressure reduces blower capacity dramatically:

https://www.acca.org

⚙️ 2. Why ECM Motors Are Both Powerful & Vulnerable

Older systems used PSC (permanent split capacitor) motors. These blowers delivered the same RPM no matter what pressure they faced. If resistance increased, airflow decreased.

You’d feel it.

Rooms got uncomfortable.

Temperature dropped.

Blower slowed down.

It was obvious.

ECM motors are different. They “fight.”

When duct resistance goes up, an ECM blower will:

-

increase torque

-

increase RPM

-

increase watt draw

-

ramp up speed

-

push harder against the restriction

This gives the appearance of strong airflow, but at a cost.

📌 ECM motors overwork themselves when:

-

filters are restrictive

-

return ducts are undersized

-

supply ducts are undersized

-

coil is clogged

-

static is too high

-

registers are closed

-

flex duct is kinked

-

transitions are poorly shaped

ASHRAE confirms: ECM motors are efficient under good static pressure but lose efficiency rapidly under high resistance.

https://www.ashrae.org/technical-resources

🧠 Samantha’s translation:

Your ECM motor will silently destroy itself trying to fix your duct problems.

🏗️ 3. Samantha’s Static-Pressure Architecture (SPA): The Framework That Makes ECM Motors Thrive

This is the architecture I use when evaluating or designing airflow systems for any home—whether new construction, retrofits, or renovations.

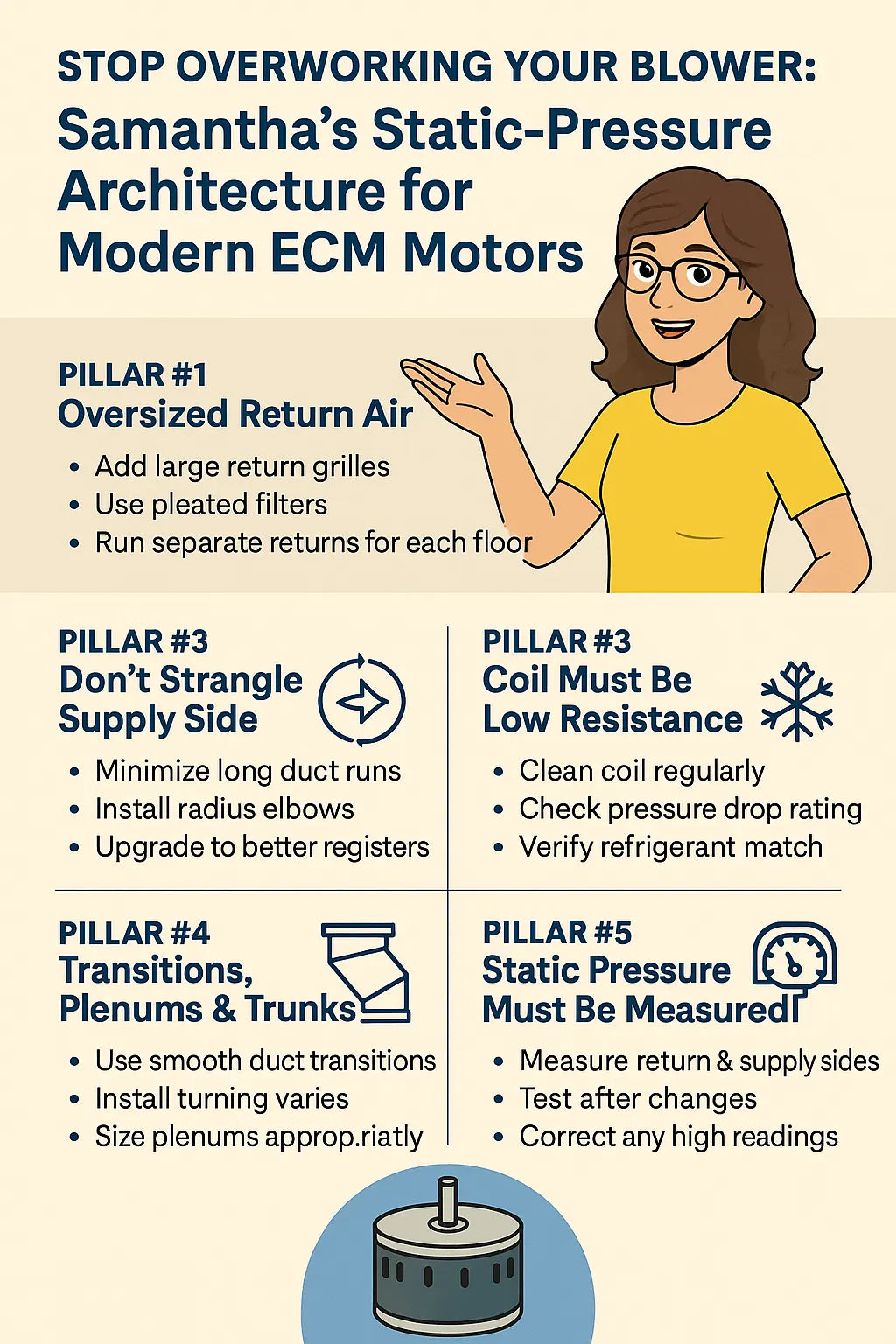

SPA includes five pressure pillars:

1️⃣ Pillar #1 — Oversized Return Air (The Foundation)

Icon: 🔄

If you only fix ONE thing in your home, fix the return side.

Most homes are return-starved, meaning:

-

return grilles are too small

-

return ducts are too small

-

only one return exists for the entire home

-

filters are too restrictive

-

static pressure spikes during heating & cooling

ENERGY STAR identifies return airflow as a top cause of poor HVAC efficiency:

https://www.energystar.gov/products/air_cleaners

🧠 Samantha’s design target:

-

1 square foot of return grille per 350 CFM

-

Two-story homes need at least 2–3 return zones

-

Use deep-pleat filters (4–5 inches) to reduce pressure

A 3.5-ton system needs 1,400 CFM, so your return grille area should be around:

1,400 ÷ 350 = 4 sq. ft. of grille area minimum

That’s about:

-

20×30 downstairs,

-

16×25 upstairs,

-

14×20 in the basement,

depending on home layout.

2️⃣ Pillar #2 — Don’t Strangle the Supply Side

Icon: 🧭

Supply ducts must deliver enough air to each room without excessive velocity or turbulence.

Common supply-side killers:

-

6" flex runs over 25 feet

-

crushed flex duct

-

cheap builder-grade registers

-

square metal boots with sharp turns

-

static-raising manual balancing dampers

-

closed registers

DOE confirms: supply restrictions increase motor strain and reduce system capacity.

https://www.energy.gov/energysaver/energy-saver

Samantha’s supply rules:

-

No more than 0.1 in. w.c. pressure drop per branch

-

Use proper-radius elbows, not hard 90° turns

-

Flex duct maximum: 5% compression allowed

-

Upgrade to high-throw registers in large rooms

-

Never manually close more than 10% of supply vents

Supply should feel like gentle wind—not a hurricane blast or a weak whisper.

3️⃣ Pillar #3 — The Coil Must Be Clean, Compatible & Low Resistance

Icon: ❄️

Your evaporator coil is the most overlooked restriction in the system.

When static pressure skyrockets at the coil:

-

airflow drops

-

blower ramps up

-

noise increases

-

ECM watt draw spikes

-

comfort evaporates

ASHRAE confirms coil cleanliness and matchability are critical for static pressure health.

https://www.ashrae.org/technical-resources

Samantha’s coil advice:

-

Clean coils every 2–3 years

-

Use correctly matched coils for R-32 or R-410A

-

Avoid microchannel coils in high-static systems

-

Confirm coil pressure drop is < 0.15 in. w.c.

-

Ensure drain pans & internal baffles aren’t blocked

A poorly chosen coil can sabotage an otherwise perfect system.

4️⃣ Pillar #4 — Transitions, Plenums & Trunks Matter More Than You Think

Icon: 🏗️

System architecture determines how smoothly air flows inside your duct network.

High-static duct architecture mistakes:

-

undersized plenums

-

no turning vanes

-

abrupt transitions

-

uninsulated trunks in attics

-

square-to-round reducers with sharp angles

-

poorly sealed seams

ACCA’s Manual D explicitly warns against “pressure spikes caused by improper transitions”:

https://www.acca.org

Samantha’s design targets:

-

Plenum height = at least 2× the coil height

-

Transitions = 3:1 slope ratio for smooth airflow

-

Trunk speed = 700–900 FPM

-

Branch velocity = 500–700 FPM

-

Turning vanes required for 90° elbows in metal duct

Think of transitions as highway interchanges—smooth ones help traffic flow; sharp ones cause pileups.

5️⃣ Pillar #5 — Static Pressure Must Be Measured, Not Guessed

Icon: 📏

The biggest mistake homeowners make?

Never measuring static pressure at all.

Static pressure measurement points:

-

Return plenum (before filter)

-

After filter (before blower)

-

After blower (before coil)

-

After coil (supply plenum)

You add the negative and the positive numbers:

Total External Static Pressure (TESP) = Return (-) + Supply (+)

ECM motors begin losing efficiency around:

-

0.6 in. w.c. (yellow zone)

-

0.7–0.8 in. w.c. (orange zone)

-

0.9+ in. w.c. (red zone—system damage!)

ENERGY STAR encourages homeowners to request airflow/pressure tests:

https://www.energystar.gov/products/central_air_conditioners

Tools I recommend (from Amazon & home testing kits):

-

manometers

-

static pressure probes

-

anemometers

-

temperature/humidity sensors

-

blower performance meters

You can test your home in 20 minutes with the right tools.

🔧 4. What Happens When Static Pressure Is Fixed? (Real Results)

When you fix static pressure, you fix everything:

Before (High Static Pressure):

-

Noisy system

-

Dust everywhere

-

Hot and cold spots

-

Short cycling

-

Rooms starved for airflow

-

ECM blower pulling high wattage

-

Poor humidity control

-

High bills, persistent discomfort

After (Optimized Static Architecture):

-

Quiet, smooth airflow

-

Strong CFM delivery to every room

-

Lower blower RPM and watt draw

-

Higher SEER2 and AFUE performance

-

Perfectly even temperatures

-

Longer furnace and AC lifespan

-

Cleaner air and lower dust levels

-

Better humidity control year-round

You can literally feel the difference in 24 hours.

📝 5. Samantha’s Static-Pressure Checklist for Homeowners

Here’s a quick-start version of my architecture:

✔️ Return Side

-

Add returns to every major zone

-

Upgrade return grille size

-

Install a deep-pleat media filter

-

Increase return duct diameter

-

Eliminate crushed flex or kinks

✔️ Supply Side

-

Upgrade to high-throw registers

-

Reduce long flex runs

-

Install proper-radius elbows

-

Correct undersized supply trunks

✔️ Coil

-

Clean coil

-

Check coil pressure drop rating

-

Verify refrigerant compatibility

✔️ Transitions

-

Smooth 3:1 slope transitions

-

Add turning vanes

-

Resize plenums

✔️ Measurement

-

Static pressure test

-

Room-by-room CFM test

-

Door-closed pressure test

-

Filter drop test

💬 Final Thoughts — Your Blower Shouldn’t Be Fighting Your Home

Your ECM motor is brilliant, efficient, and durable.

But it cannot defeat bad ductwork, a mismatched coil, a restrictive filter, or a return-starved layout.

If your system is loud…

If rooms feel uneven…

If your blower seems to run nonstop…

It’s not the motor’s fault.

Static pressure is the true enemy of comfort.

Fix that, and everything else falls into place.

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: Where Comfort Dies: Samantha’s Red-Flag Zones That Predict a Bad System Before It’s Installed