The first time a PTAC powers up, it talks to you.

Not with words — with sounds, pauses, vibrations, smells, and signals.

Most people either panic at normal noises or ignore the ones that matter. Both lead to the same outcome: unnecessary service calls or real problems missed early.

I’ve stood next to hundreds of PTACs during startup. The good ones tell a calm, predictable story. The bad ones give warnings — quietly at first.

This guide helps you translate what your PTAC is saying during startup, so you know what’s normal, what’s questionable, and what means stop right now.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

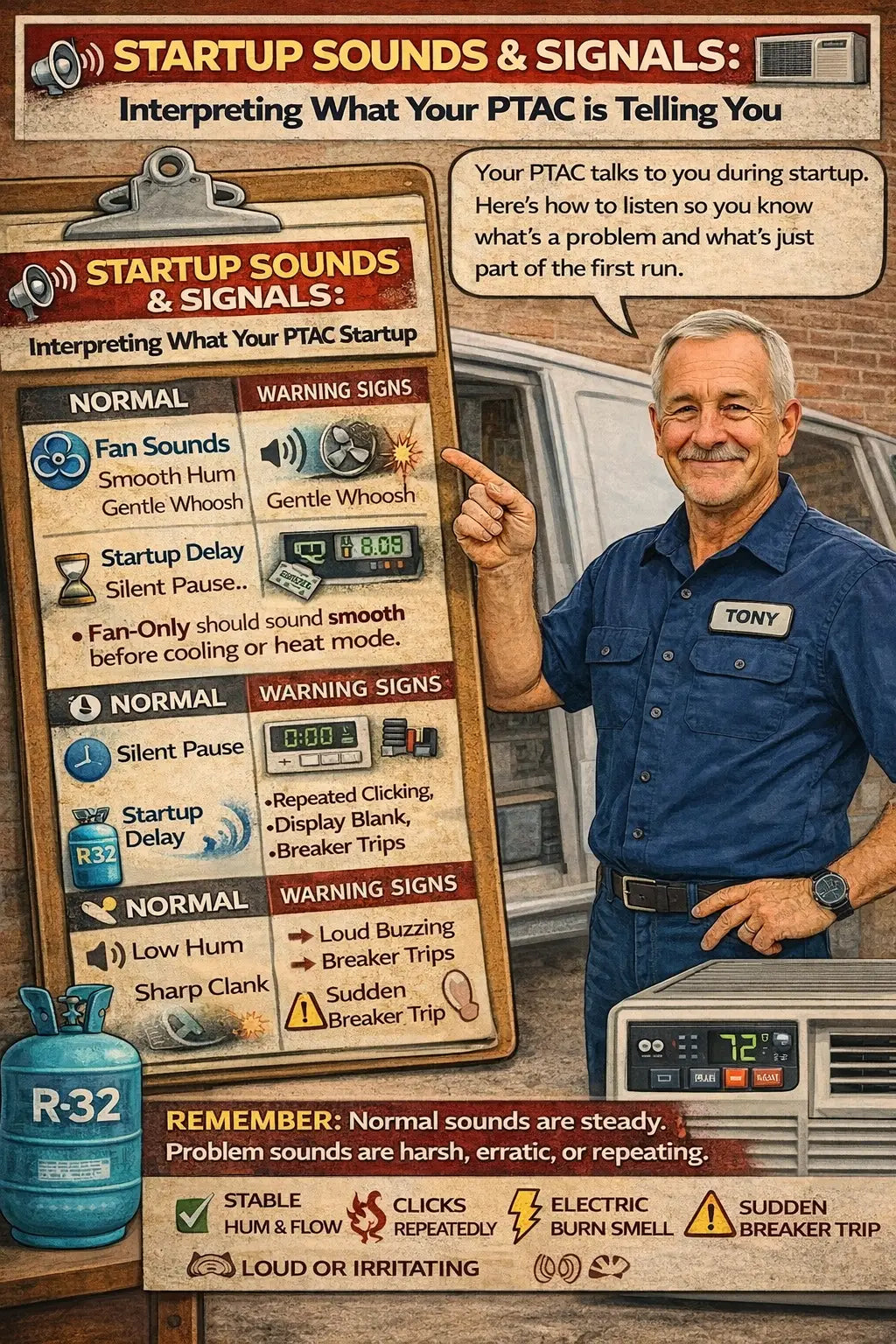

🧠 First Rule: Startup Sounds Are Diagnostic — Not Annoyances

Before we get specific, remember this:

Every startup sound has a cause.

Some causes are normal physics. Others are install mistakes. A few are genuine defects.

Your job during startup isn’t to judge loud vs quiet — it’s to judge consistent vs wrong.

🌀 Fan Sounds: The First Voice You’ll Hear

Fan operation is always the first thing to listen for.

✅ Normal fan sounds

-

Smooth, steady airflow

-

Soft whoosh of air

-

Low, even motor hum

This tells you:

-

Blower wheel is balanced

-

Nothing is rubbing

-

Air path is clear

🚫 Abnormal fan sounds

-

Clicking or ticking → often shipping debris or loose fastener

-

Scraping → fan wheel rubbing housing

-

Thumping → sleeve misalignment or warped cabinet

If fan-only mode doesn’t sound clean, do not proceed to cooling or heat.

Verified reference:

Amana PTAC Installation & Operation Manual

https://www.manualslib.com/manual/531523/Amana-Ptac.html

⏳ Silence After Power-On: What the Delay Means

One of the most misunderstood startup “sounds” is no sound at all.

After power is applied:

-

PTACs often wait 2–5 minutes

-

Control boards run checks

-

Compressor delay prevents hard starts

✅ Normal silence

-

Display powered

-

No fan or compressor yet

-

No error codes

🚫 Not normal

-

No display

-

Repeated clicking

-

Breaker trips during delay

Silence with power is patience. Silence without power is a problem.

❄️ Compressor Sounds: Clean vs Concerning

When cooling mode engages, the compressor joins the conversation.

✅ Normal compressor sounds

-

Low, steady hum

-

Slight increase in sound when it starts

-

Tone stabilizes within seconds

This means:

-

Pressure equalized properly

-

Voltage is stable

-

Refrigerant flow is normal

🚫 Warning sounds

-

Sharp metallic clank → mounting or internal issue

-

Repeated hard clicking → electrical or relay problem

-

Rapid cycling → airflow or voltage issue

Modern refrigerants like R32 create sharper but cleaner tones — that’s normal. Harsh or chaotic noise is not.

Verified reference:

EPA Refrigerant Overview (Modern Systems)

🌬️ Airflow Signals: What Your Ears and Hands Should Notice

Sound alone isn’t enough. Pair it with airflow feel.

Normal airflow signals

-

Consistent pressure from vents

-

No pulsing or surging

-

Air temperature changes gradually

Red flags

-

Airflow drops when compressor starts

-

Pulsing air → restriction or control issue

-

Loud airflow hiss → sealing or duct path issue (sleeve leaks)

Airflow problems often sound like compressor problems. That’s why fan-only testing comes first.

🔥 Heat Mode Sounds: Higher Load, Clearer Warnings

Heat mode is where electrical issues reveal themselves.

✅ Normal heat sounds

-

Fan engages first

-

Slight relay click

-

Warm air after a short delay

-

Breaker remains steady

A brief “new heater” smell is common on first use.

🚫 Heat-mode warnings

-

Loud buzzing → electrical connection issue

-

Breaker trip → undersized circuit

-

Fan delay without heat → control issue

Electric heat doesn’t whisper. If it’s unhappy, it lets you know fast.

Verified reference:

Amana PTAC Electric Heat Resources

https://www.amana-ptac.com/resources

💡 Lights, Codes, and Displays: Visual Signals Matter Too

Modern PTACs often communicate visually.

Normal indicators

-

Solid lights

-

Clear temperature display

-

Mode changes reflected immediately

Warning signs

-

Flashing LED patterns

-

Error codes

-

Display resets or flickers

Error codes during startup usually point to:

-

Voltage mismatch

-

Sensor connection issues

-

Control board protection lockouts

Don’t ignore flashing lights — they’re the PTAC’s way of documenting the problem for you.

👃 Smells at Startup: Normal vs Dangerous

Smells are signals too.

Normal smells

-

Light “new electronics” scent

-

Brief heater burn-off smell

-

Dust warming smell on first run

🚫 Dangerous smells

-

Sharp electrical odor

-

Burning plastic

-

Persistent oil or chemical smell

If a smell makes you step back instinctively, power down.

🔁 Repeating Sounds: Patterns Matter

A single noise can be harmless. A repeating one is not.

Listen for:

-

Click → pause → click (relay cycling)

-

Fan surge → drop → surge

-

Compressor start → stop → start

Repetition usually means the unit is trying to protect itself.

🚫 Sounds That Are Never “Normal”

No matter what anyone tells you, these are always wrong:

-

Grinding

-

Screeching

-

Hammering

-

Electrical arcing sounds

If you hear these, stop. Period.

📋 Startup Sound Quick-Reference Chart (Mental Version)

-

Smooth = good

-

Sharp but steady = modern normal

-

Chaotic or repeating = problem

-

Silent with display = delay

-

Silent without display = power issue

🧱 Tony’s Final Word

A PTAC doesn’t fail quietly.

It warns you — early and politely.

Startup sounds are the unit’s first conversation with you. Listen carefully, don’t rush it, and you’ll catch small problems before they become permanent ones.

Ignore them, and you’ll spend years blaming the machine for something it tried to tell you on day one.