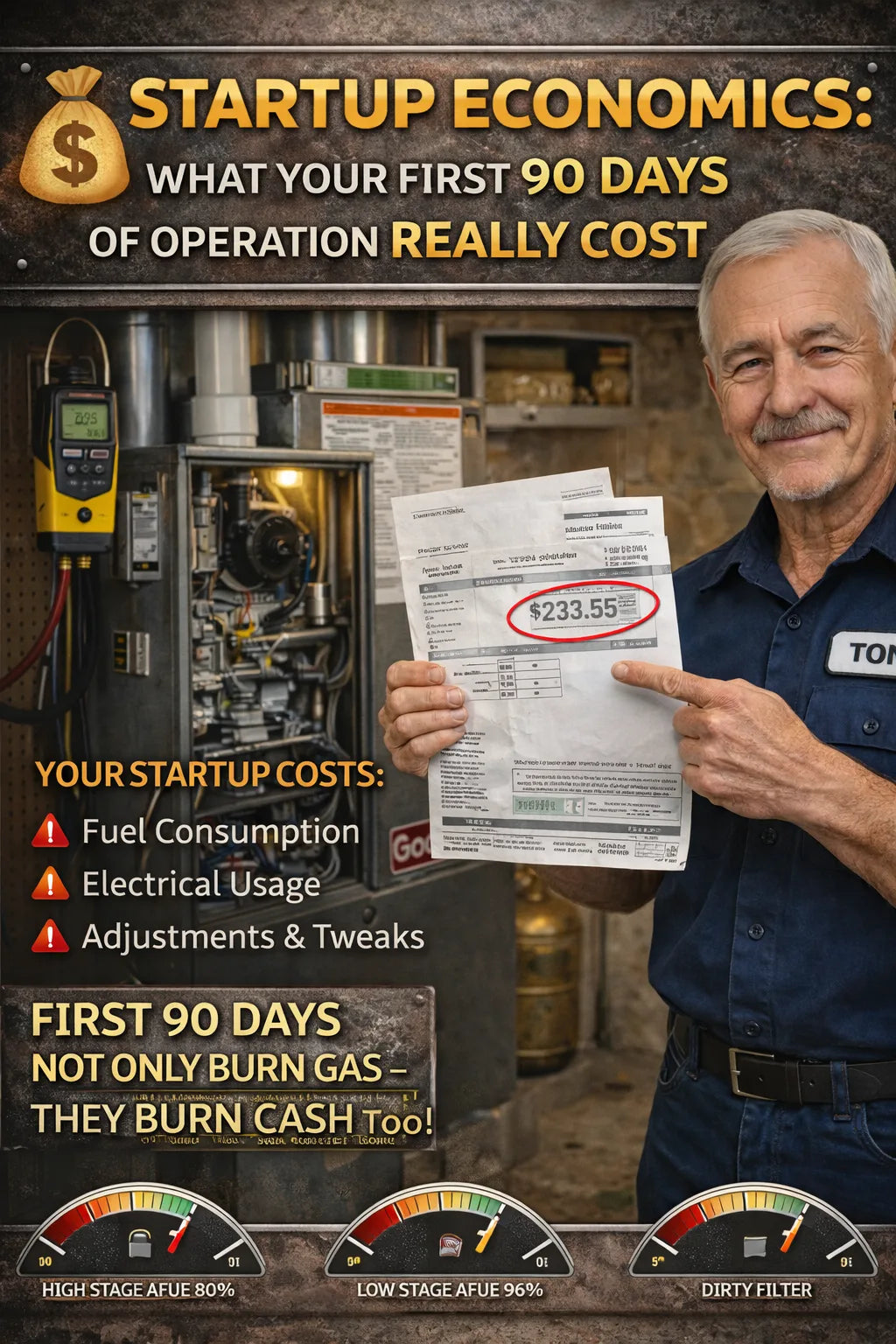

Tony here.

Let’s talk about something most furnace guides avoid:

Money. Real money. The kind that shows up on your utility bill.

When a new gas furnace fires up, homeowners usually ask one of two questions:

-

“Is it working?”

-

“Is this thing saving me money yet?”

The truth is, the first 90 days tell you almost everything about whether your system is dialed in—or quietly wasting cash. This guide breaks down what you’re actually paying during those first three months, what’s normal, what’s not, and how startup decisions directly affect your costs.

No sales fluff. Just math and experience.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

🧠 Why the First 90 Days Matter Financially

A furnace doesn’t reach “steady-state efficiency” on Day One.

During the first 90 days:

-

Controls learn the home’s heat demand

-

Homeowners adjust thermostat habits

-

Filters load with initial dust

-

Duct issues reveal themselves

-

Staging behavior becomes consistent

Tony rule:

If your costs are high in the first 90 days, they’ll stay high unless you fix something.

🔥 The Three Buckets of Startup Costs

Your early operating costs fall into three categories:

-

Fuel consumption (natural gas or propane)

-

Electrical usage (blower, inducer, controls)

-

Corrective costs (filters, adjustments, minor fixes)

Let’s break each one down.

🔥 Bucket #1: Fuel Costs (The Big One)

Gas is where most of your money goes.

What affects fuel use in the first 90 days:

-

Furnace efficiency (AFUE)

-

How often it runs in low vs high stage

-

Outdoor temperature trends

-

Thermostat settings

-

Home insulation and air leakage

A properly set up 96% AFUE two-stage furnace should:

-

Run mostly in low stage

-

Cycle longer but less aggressively

-

Use noticeably less gas than an older single-stage unit

👉 Furnace efficiency basics (DOE):

https://www.energy.gov/energysaver/furnaces-and-boilers

Tony truth:

High gas bills early almost always mean staging or airflow problems—not a “bad furnace.”

⚡ Bucket #2: Electrical Costs (Smaller, But Not Zero)

Modern furnaces use electricity to save gas.

Where electricity is used:

-

ECM blower motor

-

Inducer motor

-

Control board

-

Igniter

-

Thermostat

The good news:

-

ECM blowers are far more efficient than old PSC motors

-

Longer low-stage run times actually reduce electrical spikes

What raises electrical costs:

-

Running constantly in high stage

-

Incorrect blower speed

-

Dirty filters

-

Excessive static pressure

👉 Goodman furnace technology overview:

https://www.goodmanmfg.com/products/gas-furnaces

If your electric bill jumps noticeably, that’s a clue—not a coincidence.

🧾 Bucket #3: Corrective & “Dial-In” Costs

These aren’t failures—they’re adjustments.

Common early expenses:

-

Extra filter changes

-

Thermostat tweaks

-

Minor duct sealing

-

Drain adjustments

-

Blower speed changes

Most of these are one-time corrections, not recurring costs.

Tony rule:

Spending a little early saves a lot later.

📊 What “Normal” First-90-Day Costs Look Like

While every home is different, here’s a general picture for a well-installed high-efficiency furnace:

You should expect:

✔ Lower gas usage than your old system

✔ Slightly longer run times

✔ More even temperatures

✔ Fewer dramatic on/off cycles

✔ Predictable utility bills

If costs spike sharply or fluctuate wildly, something’s off.

🧭 How Staging Behavior Impacts Your Wallet

Two-stage furnaces save money only when staging is correct.

Low-stage operation:

-

Lower gas input

-

Higher efficiency

-

Longer cycles

-

Lower stress on components

High-stage operation:

-

Higher gas usage

-

Necessary only during peak demand

-

Should be limited in normal conditions

Tony truth:

If your furnace lives in high stage, your wallet pays the price.

🌬️ Airflow: The Hidden Cost Multiplier

Bad airflow quietly inflates costs.

Airflow problems cause:

-

Overheating

-

Short cycling

-

Higher gas use

-

Increased electrical draw

-

Comfort complaints

Common culprits:

-

Dirty filters

-

Undersized returns

-

Closed registers

-

Poor duct transitions

Fix airflow once—and your costs drop permanently.

📈 Reading Your First Utility Bills Like a Pro

Don’t just glance at the total.

Compare:

-

Usage (therms or cubic feet)

-

Average outdoor temperature

-

Billing period length

-

Previous year’s usage

If the furnace is new and usage isn’t lower, investigate—not ignore.

👉 Utility bill analysis basics:

https://www.energy.gov/energysaver/estimating-appliance-and-home-electronic-energy-use

❌ Common Startup Mistakes That Inflate Costs

Avoid these, and you save money automatically:

❌ Cranking the thermostat during cold snaps

❌ Ignoring filter maintenance

❌ Blocking return air paths

❌ Letting high stage run constantly

❌ Assuming “new” means “optimized”

New systems still need tuning.

🛠️ Smart Moves That Reduce Costs in the First 90 Days

Here’s what actually works:

✔ Use programmable setbacks wisely

✔ Change filters early and often

✔ Keep doors and returns clear

✔ Let low stage do the work

✔ Address noise or cycling immediately

Small actions add up fast.

📋 Tony’s 90-Day Cost Checkpoint

At the 90-day mark, ask yourself:

✔ Are bills lower than last year?

✔ Is comfort better and more even?

✔ Is the furnace quiet most of the time?

✔ Are run times longer but calmer?

If yes—you’re winning.

If not—it’s fixable.

🔚 Final Tony Takeaway

Startup economics aren’t about perfection—they’re about direction.

A properly installed and tuned furnace should:

-

Show savings early

-

Stabilize costs quickly

-

Reward good habits

-

Punish shortcuts

The first 90 days don’t just cost money—they teach you how your system behaves.

Learn from them, adjust early, and the furnace will pay you back every winter after that.