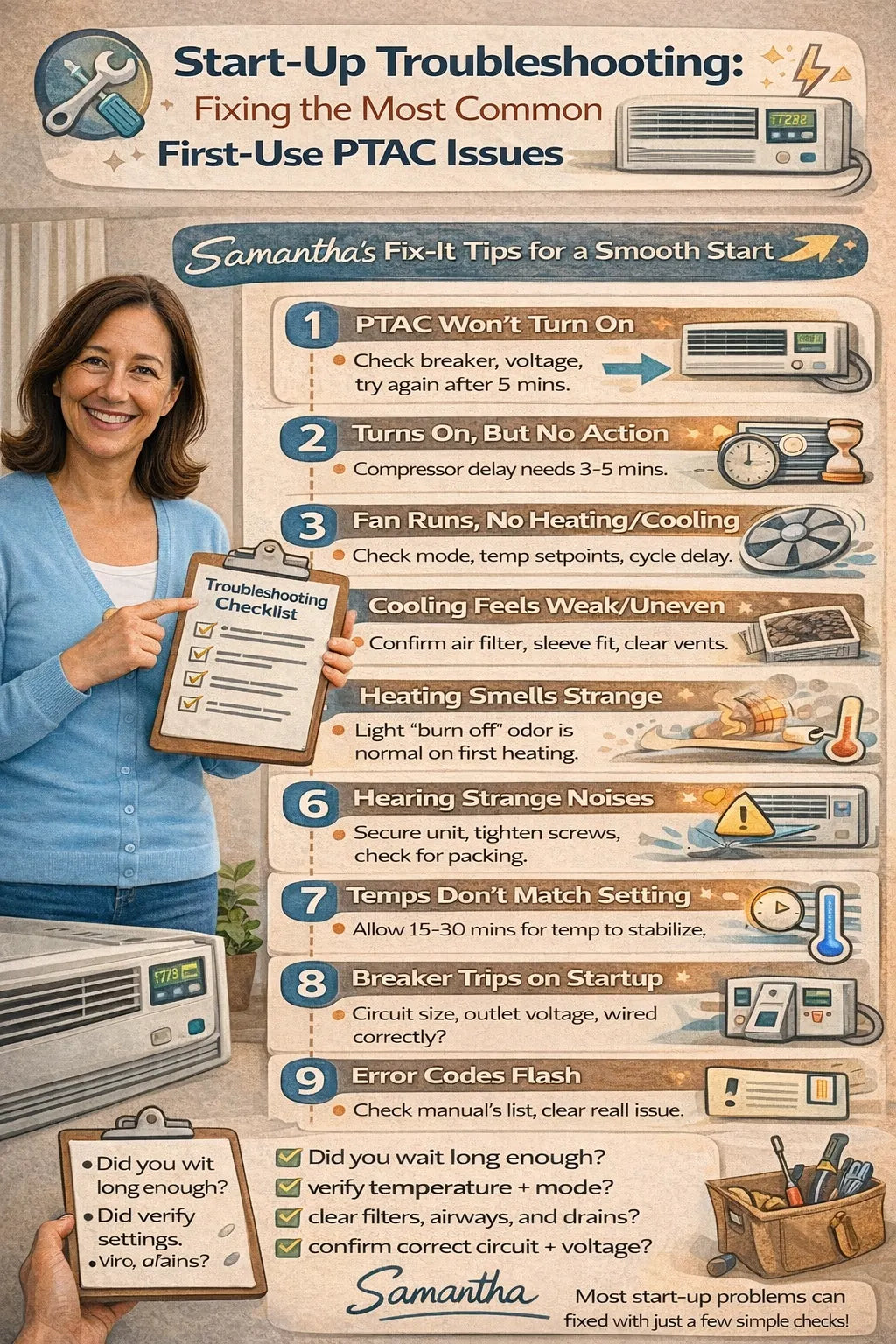

Nothing is more frustrating than installing a PTAC, powering it on for the first time—and realizing something isn’t quite right.

The good news? Most start-up issues are minor, common, and fixable without calling for service. PTAC systems are designed with built-in safeguards, which means many “problems” are actually the unit protecting itself during initial operation.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

In this guide, I’ll walk you through the most common first-use PTAC issues, what usually causes them, and exactly what to check—step by step—before you panic or pick up the phone.

🧠 First, Take a Breath: Why Start-Up Issues Are Common (and Normal)

During first use, a PTAC is:

-

Initializing control boards

-

Equalizing refrigerant pressure

-

Burning off manufacturing residue

-

Responding to a space it’s never conditioned before

That combination alone explains why first-time behavior often looks different from everyday operation.

Most start-up issues fall into three categories:

-

Electrical or control delays

-

Airflow or installation oversights

-

Normal behaviors that feel unfamiliar

Let’s break them down.

⚡ Issue 1: The PTAC Won’t Turn On at All

🔍 What This Usually Means

-

Power isn’t reaching the unit

-

The unit is in a protection delay

-

Electrical requirements aren’t met

✅ What to Check First

-

Is the breaker on and correctly sized?

-

Is the outlet supplying the correct voltage (often 208/230V)?

-

Is the power cord fully seated?

-

Did you recently cycle power? (Wait 5 minutes and try again.)

PTACs will not restart immediately after losing power—that’s intentional.

⏳ Issue 2: The Unit Turns On, but Nothing Happens

This one causes a lot of unnecessary worry.

🟢 Most Likely Cause

Compressor delay timer (usually 3–5 minutes).

✔️ What to Do

-

Leave the unit on

-

Don’t press buttons repeatedly

-

Listen for the fan—cooling or heating comes later

If nothing happens after 10 full minutes, then move on to airflow and settings checks.

👉 How HVAC systems sequence startup

🌬 Issue 3: Fan Runs, but No Heating or Cooling

🔍 Common Causes

-

Mode not selected properly

-

Temperature setpoint too close to room temp

-

Unit still in delay mode

✅ Quick Fix Checklist

-

Set temperature at least 5°F above or below room temp

-

Confirm “Cool” or “Heat” mode is selected

-

Wait a full cycle (10–15 minutes)

Fan-only operation during startup is normal and not a failure.

❄️ Issue 4: Cooling Feels Weak or Uneven

🧊 This Is Common on First Use

Especially in hot spaces that haven’t been conditioned yet.

✔️ What to Check

-

Is the air filter installed and clean?

-

Are intake or exhaust vents blocked?

-

Is the unit flush in the wall sleeve?

Cooling should improve steadily—not instantly.

👉 Cooling performance basics:

https://www.energy.gov/energysaver/air-conditioning

🔥 Issue 5: Heating Smells Strange the First Time

This one worries people—but it’s usually harmless.

🟡 Normal First-Heat Behavior

-

Slight dusty or “burning” smell

-

Lasts a few minutes

-

Disappears quickly

This is residue burning off electric heating elements.

🔴 When to Shut Down

-

Smell becomes strong or persistent

-

Visible smoke

-

Airflow stops

🔊 Issue 6: Strange Noises During Startup

🟢 Normal Sounds

-

Soft hum

-

Clicks when components engage

-

Air movement

🔴 Not Normal

-

Grinding

-

Rattling

-

Loud metallic scraping

✔️ Fixes to Try

-

Confirm unit is fully seated

-

Tighten mounting screws

-

Check for leftover packing material

Shipping materials left inside are a top cause of startup noise.

🌡 Issue 7: Temperature Isn’t Matching the Thermostat

🧠 Important to Know

During first use, PTACs take time to:

-

Sense room conditions

-

Stabilize airflow

-

Adjust cycling behavior

✔️ What Helps

-

Keep doors and windows closed

-

Avoid adjusting settings constantly

-

Give the unit 30 minutes

Frequent changes slow stabilization and confuse diagnostics.

🚨 Issue 8: Breaker Trips on Startup

This one should never be ignored.

🔍 Possible Causes

-

Incorrect breaker size

-

Shared circuit

-

Voltage mismatch

-

Loose electrical connection

🚫 Do NOT

-

Reset repeatedly

-

Use extension cords

-

Ignore repeated trips

Electrical issues require correction before continued operation.

🧰 Issue 9: Error Codes or Flashing Lights

Modern PTACs often communicate through indicators.

✔️ What to Do

-

Refer to the unit’s manual

-

Note the code or pattern

-

Power down safely before resets

Error codes are diagnostic tools, not bad news.

👉 Manufacturer support overview:

https://www.amana-ptac.com/resources

📝 Samantha’s Start-Up Troubleshooting Rule of Thumb

Before calling for service, ask yourself:

✔ Did I wait long enough?

✔ Did I verify settings and airflow?

✔ Did I check electrical supply and clearances?

✔ Did I let the unit complete a full cycle?

Most start-up issues are resolved right there.

🚀 When It Is Time to Call for Help

You should contact support if:

-

Breaker trips repeatedly

-

Loud mechanical noises continue

-

Unit never produces heating or cooling

-

Error codes persist after resets

Catching true issues early protects warranties and prevents damage.

🧠 Final Thoughts from Samantha

Start-up troubleshooting isn’t about fixing a broken system—it’s about learning how your PTAC communicates.

Once you understand what’s normal, what’s delayed, and what’s protective behavior, the anxiety fades fast. Most PTACs don’t fail at startup—they just need time, airflow, and the right conditions to settle in.

And once they do? They’re remarkably dependable.