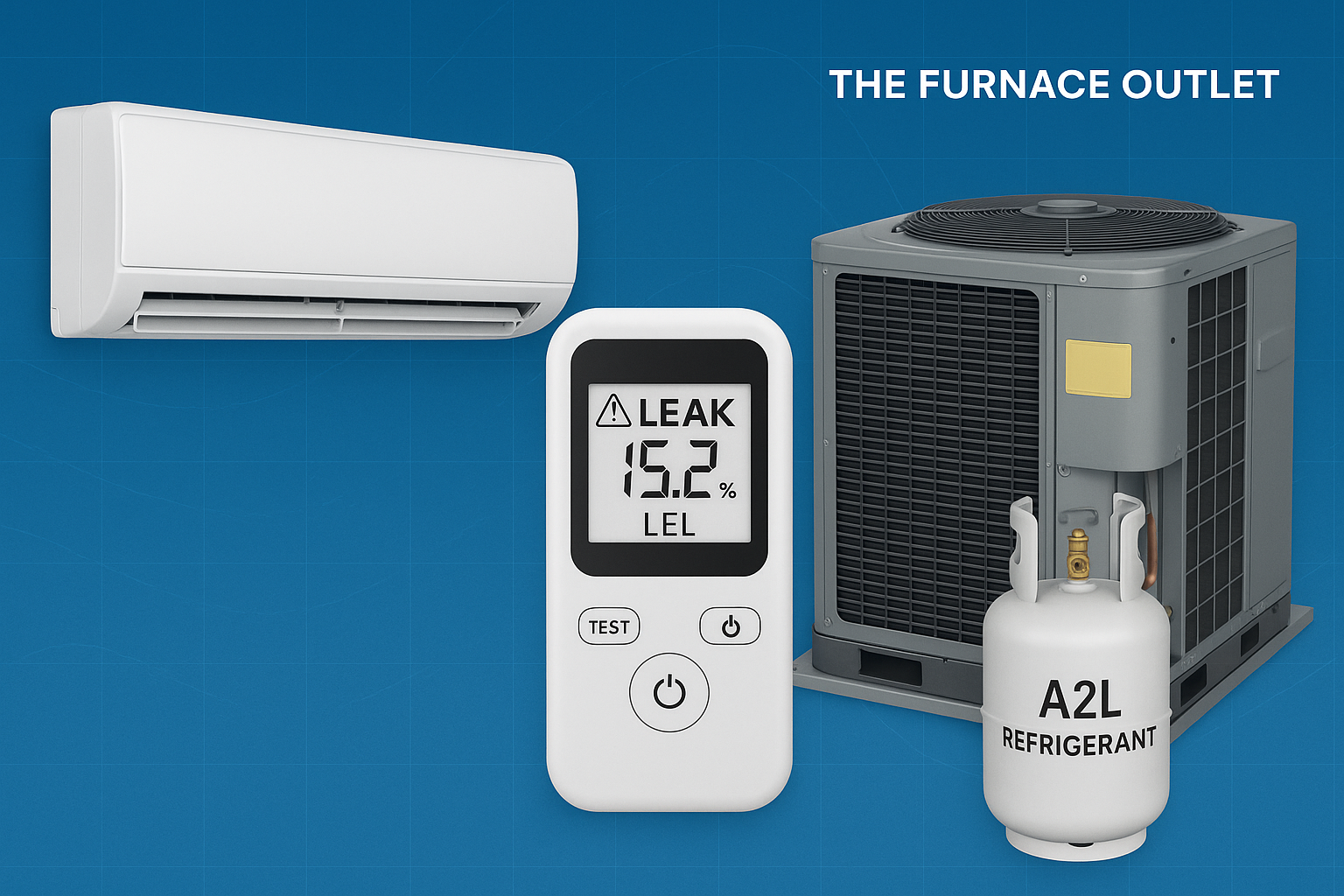

As the HVAC and refrigeration industries pivot toward greener refrigerants like A2L, safety and performance remain front and center. These mildly flammable refrigerants offer major climate benefits—but only when handled with care. That’s where sensor technology steps in.

New sensor systems do more than detect leaks—they help keep buildings safe, systems efficient, and businesses compliant. In this article, we explore how these technologies work, why they matter, and how they’re shaping the future of sustainable cooling.

Equip your system with A2L-rated leak detectors and smart accessories designed for reliable monitoring and control.

Why Leak Detection Matters More Than Ever

In systems using A2L refrigerants, leak detection isn’t just a maintenance best practice—it’s a safety requirement. Even small leaks can lead to:

-

Fire hazards due to A2L's mild flammability

-

Reduced cooling performance and energy efficiency

-

Regulatory violations and environmental penalties

-

Costly refrigerant loss and equipment wear

Proper detection helps facilities avoid these risks while reducing environmental impact. Leaking refrigerants contribute to climate change and regulatory non-compliance. Sensors give operators an early warning system—allowing them to act before a minor issue becomes a serious problem.

For a broader look at how to engineer safer, smarter A2L systems, check out Designing for A2L Success.

Inside the Toolbox: Modern Sensor Tech Explained

Leak detection used to mean sniffers and soap bubbles. Today’s sensors offer 24/7 digital surveillance.

Real-Time Monitoring

Modern sensors continuously scan for refrigerant levels and issue alerts when a leak is detected. This rapid feedback is essential in systems where A2L leaks can escalate quickly.

Smart Integration

These sensors connect to centralized controllers, cloud platforms, or building management systems (BMS). They support automated shutdowns, remote diagnostics, and regulatory reporting.

Breaking It Down: The Three Main Sensor Types

Each sensor type brings unique strengths depending on the application.

1. Infrared (IR) Sensors

-

Measure how refrigerant absorbs infrared light

-

Extremely precise—ideal for high-sensitivity applications

-

Low maintenance and long lifespan

2. Electrochemical Sensors

-

React to refrigerant gases through a chemical process

-

Durable, long-lasting, and cost-effective

-

Excellent in mixed-gas environments where cross-interference is a concern

Pair with R32 packaged heat pump systems that serve high-traffic or industrial zones with robust control.

3. Semiconductor Sensors

-

Use changes in electrical conductivity when exposed to gas

-

Rugged and dependable for industrial or high-vibration settings

-

Offer good performance in high-traffic mechanical rooms

For more on how leak detection fits into modern refrigerant strategies, see Stop Leaks Before They Start.

From Risk to Resilience: The Real Benefits of Smart Leak Detection

Enhanced Safety

Fast leak detection means faster response—protecting people, equipment, and the facility.

Lower Operating Costs

Catch leaks early and reduce refrigerant replacement, energy loss, and system strain.

Predictive Maintenance

Many sensors feed into data platforms that help forecast issues before they cause downtime.

Environmental Compliance

With accurate logs and monitoring, businesses stay compliant with EPA or F-Gas rules while reducing greenhouse gas emissions.

Want a full picture of the trade-offs involved in refrigerant selection? See R454B vs. R32 to choose smarter and safer alternatives.

Making It Work: How to Integrate Leak Sensors Effectively

Implementation is more than just buying sensors—it’s about deploying them strategically.

-

Choose the Right Sensor: Match sensitivity and sensor type to your refrigerant and system layout.

-

Install in Key Areas: Place sensors near valves, joints, compressors, and heat exchangers—anywhere a leak is likely to start.

-

Link to Monitoring Systems: Integration with your BMS or standalone display lets you view live data and alerts.

-

Maintain Regularly: Calibration and testing ensure accuracy and avoid false alarms or missed leaks.

Upgrade to R32 dual-fuel systems for added efficiency, emissions reduction, and future-ready performance.

Compliance Is Non-Negotiable: Navigating Regulations Around A2L Refrigerants

Agencies like the EPA and the EU’s F-Gas authority require:

-

Verified leak detection methods in systems above certain refrigerant thresholds

-

Logbooks of detected leaks, repairs, and follow-up testing

-

Trained and certified personnel for handling and servicing

Smart sensors make this easier by providing traceable data, real-time leak documentation, and tools for technicians to stay compliant.

Need help staying compliant across the board? Get Certified, Stay Safe offers a clear roadmap to training and regulatory alignment.

Real-World Impact: Case Studies in A2L Sensor Success

Grocery Chain Slashes Costs and Emissions

A national supermarket group installed IR sensors across its refrigeration cases. The result: a 40% drop in refrigerant loss and measurable energy savings within a year.

Manufacturing Facility Improves Uptime

After struggling with repeated failures, a plant switched to electrochemical sensors. Their alerts enabled preemptive repairs—cutting unplanned downtime in half.

Office Building Boosts Indoor Air Quality

Facility managers in a mid-rise commercial building used semiconductor sensors to monitor HVAC zones. They not only reduced refrigerant leaks, but also improved tenant comfort and air safety.

Consider DIY-ready ductless mini-splits that allow easy sensor placement and access for maintenance.

What’s Next: The Future of Leak Detection Technology

The pace of innovation is accelerating, with several promising trends on the horizon:

-

AI and Predictive Diagnostics: Algorithms trained on sensor data can detect anomalies before a leak occurs.

-

Wireless and IoT Connectivity: Easier installation, cloud-based dashboards, and mobile alerts make remote management simple.

-

Smaller, Smarter Sensors: Miniaturization allows better integration in tight spaces without losing accuracy.

-

Self-Calibrating Systems: New models adjust themselves, reducing manual upkeep and false positives.

Final Thoughts: A Safer, Smarter Path Forward

In a world where HVAC systems are expected to be both sustainable and safe, leak detection isn’t optional—it’s strategic. The newest generation of A2L-compatible sensors offers a clear path forward:

-

Reduce operational risk

-

Meet modern compliance standards

-

Support long-term performance and cost savings

By integrating smart sensor technology today, you’re not just preventing leaks—you’re future-proofing your entire system.

Ready to protect your A2L system with smart technology?

Shop A2L-ready accessories and sensor-compatible HVAC systems at The Furnace Outlet—engineered for performance, safety, and regulatory confidence.