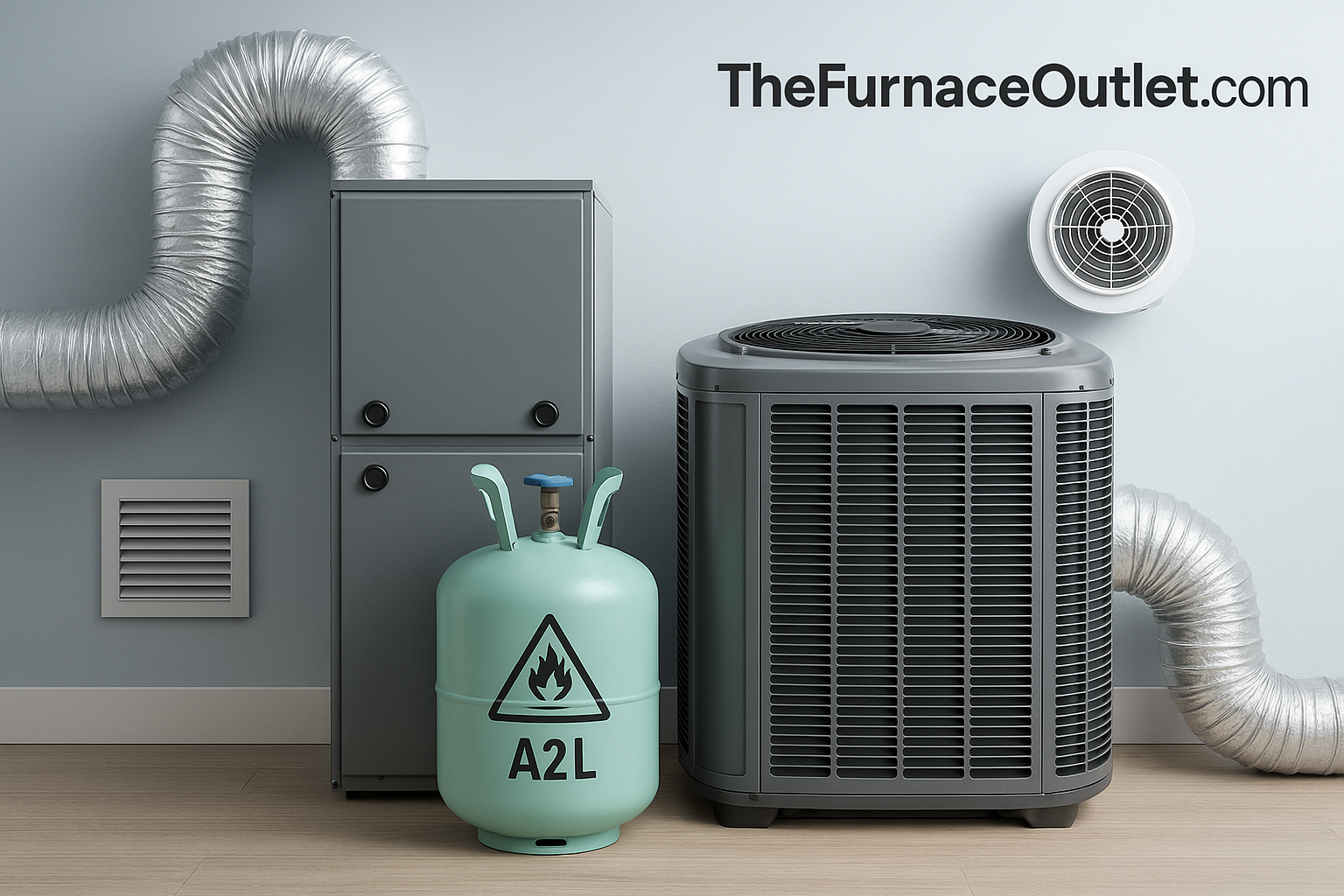

As the HVAC industry continues its pivot toward more sustainable solutions, the adoption of A2L refrigerants has become a critical step forward. These low-global-warming-potential (GWP) refrigerants are playing a key role in reducing environmental impact—but with this progress comes a need for increased safety and regulatory diligence. While A2L refrigerants offer promising environmental benefits, their mild flammability and specific handling requirements make proper ventilation not just important—but essential.

In this guide, we explore practical, field-tested ventilation strategies tailored specifically for A2L refrigerants. From understanding the core risks to integrating smart system design and real-time monitoring, this article is your roadmap for navigating A2L adoption while ensuring code compliance and system integrity.

Start with R-32 air conditioner + air handler systems designed to meet today's A2L safety expectations.

The Hidden Risks: Why A2L Refrigerants Require Special Care

At first glance, A2L refrigerants might seem like a win-win—low GWP, lower toxicity, and increasing regulatory support. But beneath their environmental advantages lies a critical safety profile: A2Ls are mildly flammable. While not as volatile as Class 2 or 3 refrigerants, their potential to ignite under certain conditions requires a thoughtful approach to system design and ventilation.

Three key hazards make A2Ls unique:

-

Flammability – Though mild, the risk becomes more pronounced in confined spaces where leaked refrigerant may concentrate near an ignition source.

-

Asphyxiation – A significant leak can displace oxygen, particularly in enclosed or poorly ventilated environments, creating a suffocation hazard.

-

Long-term exposure – While less toxic overall, chronic low-level leaks may impact indoor air quality and occupant health over time.

Understanding these risks is the first step. Mitigating them requires proactive design, effective airflow management, and strict adherence to codes and standards.

Code Compass: Navigating the Regulatory Framework for A2L Safety

To safely implement A2L refrigerants, HVAC professionals must align with a variety of regulations designed to protect systems, structures, and people. Some of the key standards include:

-

ASHRAE Standard 15: Sets comprehensive safety requirements for refrigeration systems, including those that use A2Ls. It covers equipment design, installation practices, and safety controls.

-

EN 378 (Europe): Provides guidelines on environmental and human safety, emphasizing ventilation and leak detection in systems using flammable refrigerant.

-

IMC & IBC (U.S. Building Codes): Govern mechanical and structural elements of buildings, ensuring refrigerant systems comply with ventilation, containment, and occupancy safety codes.

Compliance isn't optional—it’s a fundamental component of responsible system design. These standards not only reduce liability but also serve as best-practice roadmaps for sustainable and safe installations.

Air in Motion: Smart Ventilation Tactics to Manage A2L Hazards Ventilation is the linchpin of A2L refrigerant safety. Done right, it disperses leaks before they become hazards. Done wrong—or overlooked—it can become a silent failure point.

Ventilation is the linchpin of A2L refrigerant safety. Done right, it disperses leaks before they become hazards. Done wrong—or overlooked—it can become a silent failure point.

Mechanical Ventilation: Your First Line of Defense

Mechanical ventilation systems—fans, ducts, and exhaust configurations—form the core of modern refrigerant containment strategies. To be effective, these systems should:

-

Be sized based on room volume and refrigerant charge limits.

-

Ensure continuous airflow in high-risk areas like mechanical rooms.

-

Include localized exhausts near potential leak points to capture and redirect refrigerants safely.

Strategic Vent Placement

Ventilation isn’t just about airflow—it’s about control. Strategic placement of intake and exhaust vents is vital:

-

Locate exhaust vents near floor level for heavier-than-air refrigerants.

-

Avoid vent outlets near potential ignition sources.

-

Consider additional vents in dead zones where refrigerant could pool undisturbed.

Natural Ventilation as a Supplement

While mechanical ventilation carries the load, natural airflow—from operable windows, cross-venting corridors, or gravity vents—can provide valuable backup and efficiency gains. It’s especially useful in low-occupancy or residential environments.

Build It Right: Designing HVAC Systems with A2L Safety at the Core

To safely use A2L refrigerants, system design must evolve beyond legacy standards.

Choose the Right Components

A2L-compatible components include:

-

Flame-retardant piping and insulation

-

A2L-rated valves, fittings, and expansion devices

-

Materials that resist chemical breakdown over time

Plan for the Unexpected

Good design also means planning for worst-case scenarios. Include:

-

Integrated leak detection systems

-

Automatic ventilation kick-on with leak alerts

-

Pressure relief valves and containment zones

Size Matters

Oversized systems can short-cycle and cause unnecessary stress, while undersized units can run hot and leak-prone. Accurate load calculations help avoid these pitfalls and maximize performance with safety in mind.

Stay Ahead: Monitoring, Maintenance, and Early Detection

Even the best-designed system can fail without proper upkeep. Maintenance practices for A2L systems need to be more proactive and technology-driven.

Visual and Instrumental Inspections

Frequent inspections—both visual and sensor-based—should check:

-

Fittings and joints for leaks

-

Heat exchangers for corrosion

-

System pressures and refrigerant levels

Leak Detection Tools

Invest in precision tools like:

-

Infrared or ultrasonic leak detectors

-

Real-time gas sensors

-

Refrigerant monitors integrated with BMS (Building Management Systems)

Preventive Maintenance

Regular coil cleaning, filter changes, and component testing reduce the risk of stress fractures or microleaks that can lead to larger hazards over time.

Equip your service team with A2L-ready HVAC accessories like leak sensors, sealant kits, and pressure gauges.

Listen to the System: The Vital Role of Sensors and Alarms

Smart sensors provide the early warnings needed to avert disaster.

-

Refrigerant Leak Sensors: Detect specific refrigerant signatures and alert maintenance teams before concentrations reach dangerous levels.

-

Oxygen Depletion Sensors: Monitor air composition in enclosed spaces and trigger alarms if oxygen levels drop too low.

-

Integrated Alarm Systems: Connect to facility BMS, enabling alerts via audio, visual signals, and mobile notifications.

These tools are not just add-ons—they are essential, always-on safety measures that keep occupants protected and ensure rapid incident response.

Add smart-compatible R-32 mini-splits that integrate with modern control systems for real-time monitoring.

Pitfalls to Avoid: Common Ventilation Missteps That Compromise Safety

Even well-intentioned designs can falter due to avoidable errors.

-

Underestimating Ventilation Needs: Don’t rely on generic airflow metrics. Tailor to refrigerant type, volume, and space dimensions.

-

Poor Vent Placement: Improperly located vents can concentrate rather than disperse gases. Position them with airflow modeling in mind.

-

Neglected Maintenance: Ventilation systems require care too. Dirty filters, broken fans, or clogged ducts can render even the best designs ineffective.

Staying vigilant helps maintain both compliance and confidence in your systems.

Real-World Success: Case Studies in A2L Safety Done Right

A Corporate Retrofit, Done Sustainably

A Fortune 500 office in the Midwest retrofitted its chiller system with A2L refrigerants. They:

-

Added smart exhaust fans with airflow sensors

-

Installed vented mechanical enclosures

-

Integrated alarms into their building's automation system

Result: 100% code compliance, no incidents, and improved IAQ scores. For commercial-grade upgrades, explore R-32 packaged heat pumps built for compliance and scale.

Manufacturing Plant Takes No Chances

An industrial plant swapped out legacy refrigerants and went all-in with a redesigned HVAC layout. Continuous airflow, pressure monitors, and dedicated leak detection zones gave employees confidence in the upgrade.

Residential Project Blends Nature and Tech

In a modern housing development, a hybrid ventilation approach combined mechanical ducting with passive airflow architecture. Result: better indoor air quality, higher energy efficiency, and safe refrigerant deployment without excess complexity.

Looking Ahead: What’s Next for A2L Safety in HVAC?

As technology evolves, HVAC systems will become more intuitive, automated, and responsive. Expect advancements in:

-

AI-powered monitoring systems

-

Self-healing sensors

-

Modular ventilation add-ons

-

Automated compliance reporting

Regulatory bodies will also continue updating safety codes as A2Ls become the standard. Professionals who stay ahead of these changes will not only protect their clients but also build more sustainable, future-ready systems.

Choose R-32 PTAC units designed for easy, code-compliant installs in commercial settings.

Final Thoughts: Safety as a Design Principle, Not a Checkbox

Using A2L refrigerants isn’t just about adopting greener options—it’s about evolving the entire ecosystem of HVAC design and maintenance. With the right combination of engineering foresight, modern ventilation tactics, and vigilant upkeep, professionals can confidently embrace A2Ls without compromising safety.

By integrating these best practices, you’re not only meeting today's codes—you’re building tomorrow’s safer, smarter HVAC systems.

Ready to build smarter, safer HVAC systems?

Browse A2L-compliant tools and systems at The Furnace Outlet—built for the future of ventilation, safety, and sustainability.