🔧 The Role of Return Air Ducts in Your HVAC System

👨🔧 “Tony here. I’ve said it before and I’ll say it again—the return ducts are the lungs of your HVAC system. The supply pushes air out, but without returns pulling that air back in, you’ve got no cycle. You’re choking the system.”

Key functions of return air ducts:

-

Maintain balanced air pressure in the home.

-

Pull air back to be filtered & reconditioned.

-

Protect indoor air quality (IAQ) by catching dust/pollutants.

-

Keep energy use efficient by reducing system strain.

📎 HVAC.com explains why return air vents are critical for comfort & efficiency.

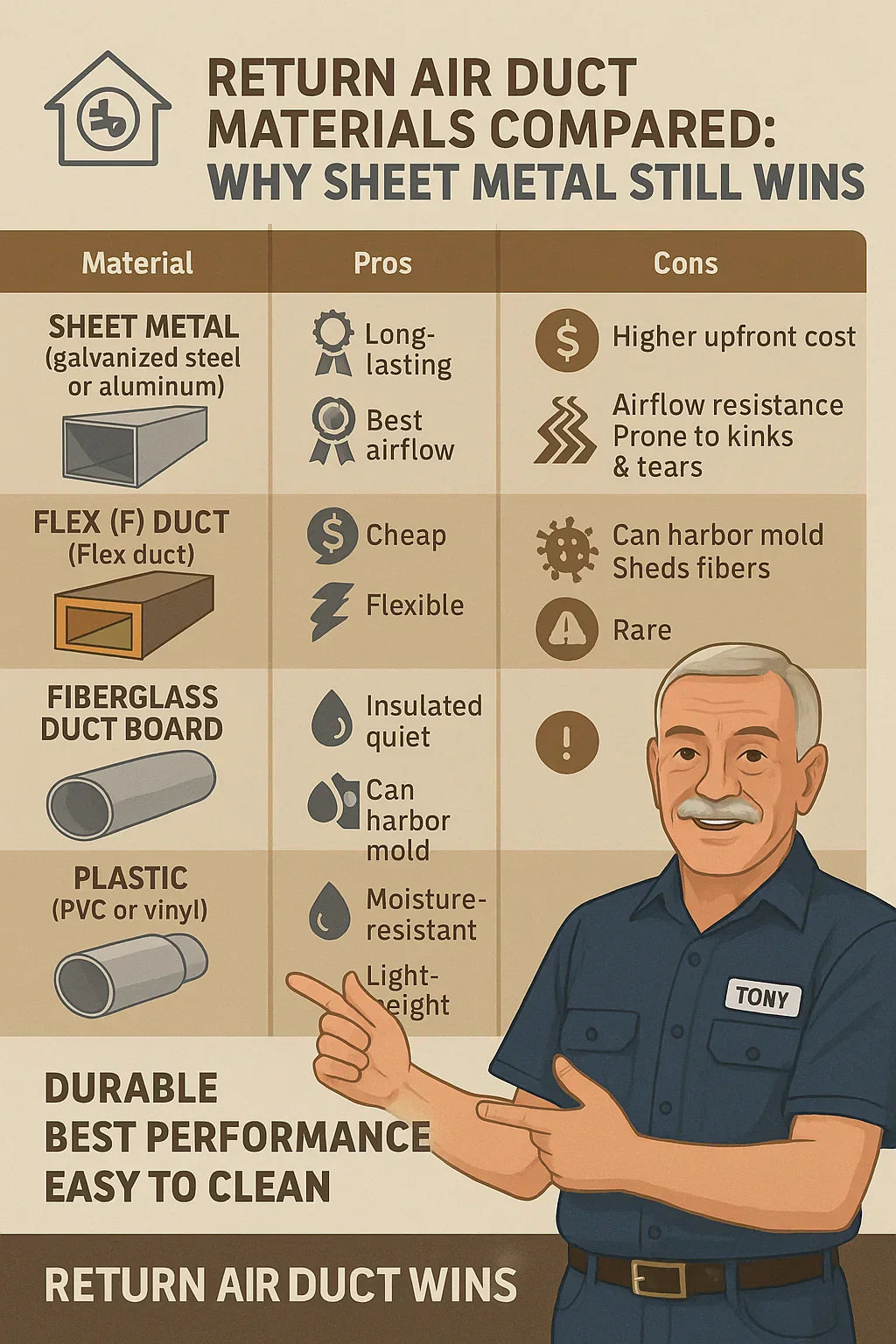

🧰 The Main Duct Materials You’ll See in Homes

Let’s break down the most common types of duct materials you’ll encounter in return air setups:

1. Sheet Metal (Galvanized Steel or Aluminum)

-

Strong, rigid, and industry standard for decades.

-

Smooth interior walls mean less friction and less dust buildup.

-

Typically used in both residential and commercial installs.

2. Flexible Duct (Flex Duct)

-

Made of a plastic inner liner with a metal coil, wrapped in insulation.

-

Lightweight, cheap, and easy to snake around tight spaces.

-

Often used as a connector between sheet metal trunks and vents.

3. Fiberglass Duct Board

-

Made from compressed fiberglass panels with a foil exterior.

-

Naturally insulated and absorbs sound.

-

Common in some regions, especially in the South.

4. Plastic (PVC or Vinyl Ducting)

-

Rare for full duct systems.

-

Used occasionally for specific applications (indoor pools, exhaust).

-

Resistant to moisture but limited lifespan.

⚖️ Deep Dive: Pros & Cons of Each Material

| Material | Pros | Cons | Best Use Case |

|---|---|---|---|

| Sheet Metal | Durable, long lifespan (30+ yrs), smooth airflow, mold resistant, easy to clean | Higher upfront cost, requires skilled install | Main return trunks & supply ducts |

| Flex Duct | Cheap, flexible, fast install | Airflow resistance, prone to kinks/tears, short lifespan | Short runs & connections |

| Fiberglass Board | Built-in insulation, quiet, lightweight | Hard to clean, mold risk in humid areas, fibers can degrade | Warm climates, small systems |

| Plastic (PVC) | Moisture resistant, lightweight | Rarely code-approved for full systems, lower efficiency | Specialty use (humidity-prone rooms) |

📎 Energy.gov confirms duct material affects efficiency & lifespan.

💨 Airflow Efficiency & Performance Comparison

Airflow matters more than almost anything else in duct design.

-

Sheet Metal → Smooth interior surface = least resistance, best airflow.

-

Flex Duct → Corrugated interior slows air, adds resistance.

-

Fiberglass Board → Airflow ok, but interior can shed fibers.

-

Plastic Ducts → Mixed results; not designed for full-system airflow.

📎 Hartman Brothers HVAC explains that poor duct choice reduces airflow efficiency.

💵 Cost Breakdown: Installation & Maintenance

-

Sheet Metal:

-

Install cost: $10–$20 per linear foot

-

Maintenance: Easy to clean, rarely replaced

-

-

Flex Duct:

-

Install cost: $3–$5 per linear foot

-

Maintenance: Must be replaced every 10–15 years

-

-

Fiberglass Duct Board:

-

Install cost: $5–$10 per linear foot

-

Maintenance: Difficult to clean, replacement often needed in 20 yrs

-

-

Plastic Ducts:

-

Install cost: Varies, not typical

-

Maintenance: Rare use

-

Tony’s Take: “Flex duct may look cheaper upfront, but when you replace it twice in the same time sheet metal is still going strong, who’s really saving?”

🌎 Durability, Lifespan & Environmental Impact

-

Sheet Metal: 30–50 years if sealed/insulated; recyclable.

-

Flex Duct: 10–15 years; ends up in landfills.

-

Fiberglass Board: 20 years max; tough to recycle.

-

Plastic: Varies, but not eco-friendly.

📎 Trane notes proper material choice extends duct lifespan significantly.

🏆 Why Sheet Metal Still Wins

👨🔧 “I’ve replaced more crushed flex ducts than I can count. I’ve seen fiberglass duct board soaked with mold. And I’ve had to re-run PVC because it just wasn’t doing the job. But you know what I rarely replace? A good old sheet metal return duct. They’re built like tanks.”

Reasons sheet metal stays on top:

-

Airflow – smooth, efficient, no wasted energy.

-

Durability – decades-long lifespan.

-

Cleanliness – easy to vacuum or sanitize.

-

Mold Resistance – metal doesn’t hold moisture.

-

Value – higher upfront cost, but lowest lifetime cost.

📎 HVAC.com calls sheet metal ducts the industry’s most efficient option.

🚫 Common Mistakes Homeowners Make Choosing Duct Materials

-

Going with all flex duct because it’s cheap.

-

Using fiberglass duct board in humid areas (mold city).

-

Forgetting to seal & insulate sheet metal (wastes energy).

-

Mixing materials in ways that cause weak airflow balance.

📎 Southern Living warns that poor duct choices lead to higher HVAC costs.

🛠️ Tony’s Pro Tips for Picking the Right Duct for Your Home

-

Use sheet metal for returns and main trunks.

-

Flex duct only for short, tight connections.

-

Never let duct board get exposed to moisture.

-

Seal everything with mastic or HVAC foil tape (NOT regular duct tape).

-

Ask your installer about duct gauge—thicker means quieter and tougher.

📎 Wamboldt HVAC stresses that airflow balance starts with proper duct material selection.

❓ FAQs About Return Air Duct Materials

Q: Can I mix sheet metal and flex ducts?

Yes—but only use flex for short runs. Don’t run 20 feet of flex for a main return.

Q: Why is fiberglass duct board so common in the South?

Because it’s pre-insulated and reduces noise—but it struggles in humid climates.

Q: Is PVC ever a good choice?

Not for main ductwork. It’s more of a specialty solution.

Q: How long should my return ducts last?

-

Sheet metal: 30–50 years

-

Flex: 10–15 years

-

Fiberglass: 20 years

✅ Final Word from Tony

👨🔧 “At the end of the day, ductwork isn’t the flashiest part of your HVAC system. But it’s the backbone. And if you want something that’ll keep your system breathing easy for decades, sheet metal is still the champ. Flex ducts have their place, fiberglass has its niche, but nothing beats good old-fashioned galvanized steel for return air ducts. Trust me—I’ve been crawling through attics and basements long enough to know.”

In the next topic we will know more about: Improving Indoor Air Quality with Proper Return Duct Design