One of the most common PTAC questions I hear is:

“How much of this can I do myself… and when am I supposed to call someone like you?”

That’s a fair question. You don’t want to overpay for service you don’t need—but you also don’t want a small issue turning into a burned-out unit.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

After decades in the field, here’s the truth:

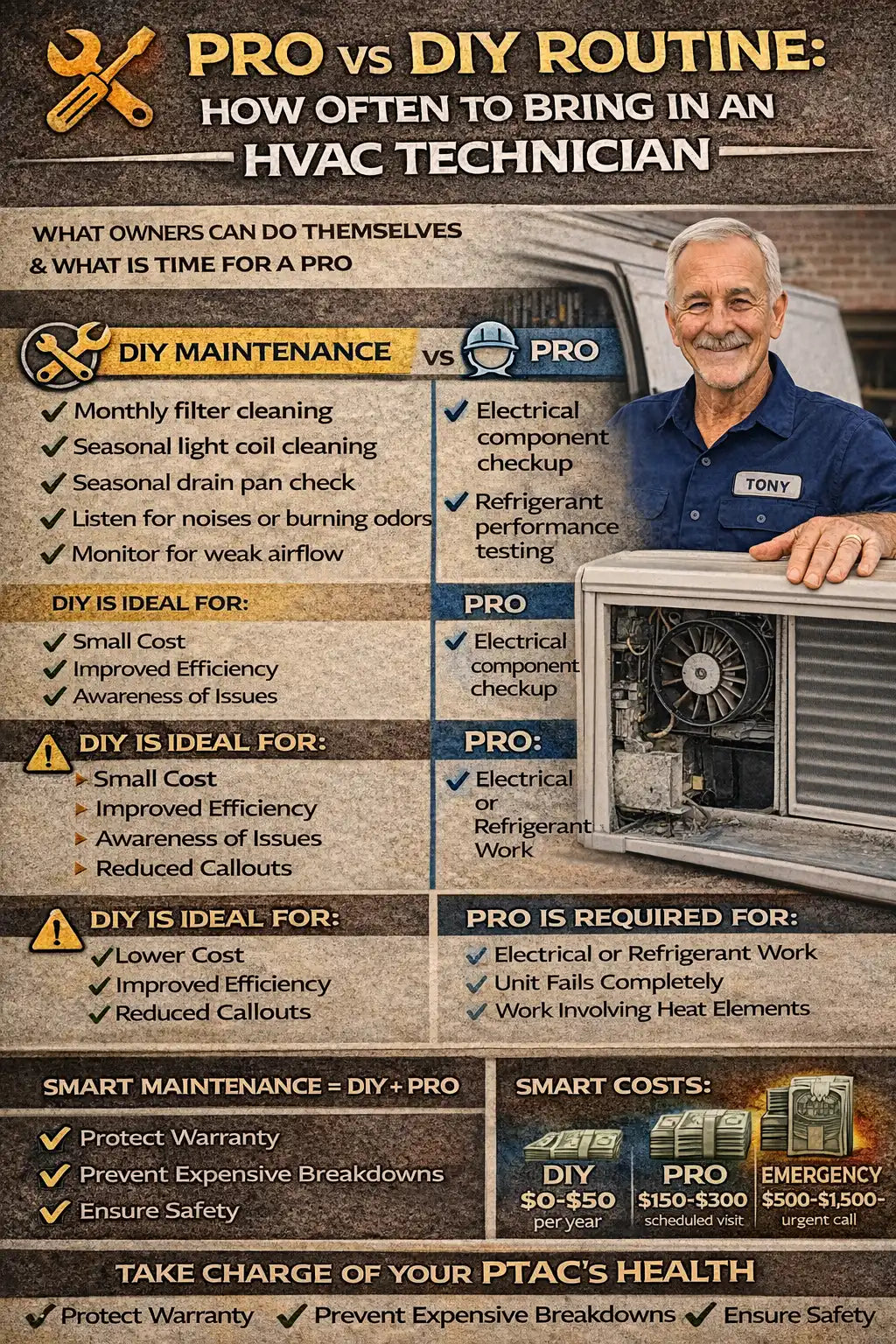

The smartest PTAC owners don’t choose DIY or professional service—they use both, on purpose.

This guide shows you how to build a balanced maintenance routine that saves money, protects warranties, and avoids emergency repairs.

🧠 Why PTACs Need a Mixed Maintenance Strategy

PTACs are compact, powerful systems that combine:

-

High-voltage electrical components

-

Motors and blowers

-

Refrigeration circuits

-

Heating elements (on many models)

Some tasks are simple and safe. Others require tools, training, and licensing.

Trying to treat a PTAC like a window AC—or like a full central system—usually leads to mistakes.

🔧 What DIY Maintenance Should Cover (And Does Well)

DIY work shines in cleanliness, awareness, and early detection.

🧽 DIY Task Category #1: Cleanliness & Airflow

These are owner-level, high-impact tasks.

What You Should Do Yourself

-

Clean or replace filters regularly

-

Clean front grille and air intake

-

Light-clean coils when needed

-

Inspect drain pan and moisture areas

-

Keep vents unobstructed

These tasks prevent:

-

Overheating

-

Poor efficiency

-

Noise complaints

-

Premature component failure

ENERGY STAR confirms regular airflow maintenance improves HVAC efficiency

https://www.energystar.gov/saveathome/heating-cooling

👂 DIY Task Category #2: Observation & Monitoring

Your senses are powerful tools.

DIY Monitoring Includes

-

Listening for new noises

-

Noticing airflow changes

-

Watching for short cycling

-

Smelling unusual odors

-

Tracking performance changes

Most PTAC failures give warnings. DIY awareness catches them early.

📆 DIY Task Category #3: Routine Scheduling

DIY maintenance keeps the system stable between professional visits.

Smart DIY Schedule

-

Monthly filter checks

-

Seasonal visual inspections

-

Pre-summer and pre-winter testing

Consistency reduces emergency calls dramatically.

🚫 Where DIY Should STOP (And Often Goes Too Far)

This is where good intentions turn into expensive repairs.

⚡ Electrical Repairs (Always Pro Territory)

DIY should never include:

-

Replacing relays or capacitors

-

Tightening live electrical connections

-

Testing voltage or continuity

-

Modifying wiring

PTACs often run on 208/230V—mistakes are dangerous.

The U.S. Department of Energy stresses licensed service for electrical HVAC repairs

https://www.energy.gov/energysaver/energy-saver

❄️ Refrigeration Work (Always Pro)

If it involves:

-

Refrigerant

-

Pressure

-

Sealed system components

…it’s not DIY.

Signs you need a pro:

-

Ice buildup

-

Weak cooling after airflow checks

-

Oily residue on coils

Only licensed technicians can legally service refrigerant systems.

🔥 Heating Element Replacement (Pro Required)

Electric heat elements draw high current.

DIY replacement risks:

-

Fire hazards

-

Control board damage

-

Warranty voiding

Visual inspection is fine. Replacement is not.

👨🔧 What a Professional HVAC Technician Brings

A good technician does more than clean.

🧪 Pro-Level Diagnostics

Technicians can:

-

Measure electrical loads

-

Test safety switches

-

Verify airflow vs heat output

-

Identify failing motors before they seize

ASHRAE emphasizes professional diagnostics for HVAC reliability

https://www.ashrae.org/technical-resources

🛠️ Deep Service You Can’t DIY

Pro maintenance may include:

-

Electrical tightening under load

-

Motor testing

-

Control board diagnostics

-

Heat strip amperage checks

-

Refrigerant performance testing

This prevents failures DIY can’t detect.

🛡️ Warranty & Code Compliance

Professional service:

-

Protects manufacturer warranties

-

Meets electrical and safety codes

-

Provides documentation for property managers

Amana and other manufacturers expect licensed service for internal repairs

https://www.amana-hac.com

📅 So… How Often Should You Call a Pro?

Here’s the practical answer.

🏠 Residential or Light Use

-

DIY: Monthly + seasonal

-

Professional: Every 12–24 months

If DIY is consistent, biennial service is often enough.

🏨 Rentals, Hotels, High-Use Spaces

-

DIY/Staff: Monthly

-

Professional: Annually

High run-time demands more oversight.

❄️ Older Units or Heavy Heating Use

-

DIY: Monthly

-

Professional: Annually, before heating season

Electric heat stresses components—don’t skip pro checks.

🚨 Always Call a Pro Immediately If…

-

Breaker trips repeatedly

-

Burning or electrical smells occur

-

Heat or cooling fails completely

-

Water reaches electrical components

-

Grinding or screeching noises appear

Delaying service increases repair cost.

CDC guidance highlights moisture and electrical risks in HVAC systems

https://www.cdc.gov/mold-health/about/index.html

💸 Cost Comparison: DIY vs Pro vs Emergency

| Maintenance Type | Typical Cost |

|---|---|

| DIY annual care | $0–$50 |

| Scheduled pro visit | $150–$300 |

| Emergency repair | $500–$1,500+ |

Preventive service pays for itself.

🧠 Tony’s Rule of Thumb (Real-World Logic)

Here’s how I explain it to owners:

If the task improves cleanliness or awareness—DIY it.

If it involves electricity, refrigerant, or replacement—call a pro.

That line saves money and keeps you safe.

🧯 Liability & Insurance Considerations

DIY electrical or refrigerant work can:

-

Void warranties

-

Complicate insurance claims

-

Shift liability to the owner

Professional service protects more than the unit—it protects you.

EPA guidance stresses proper HVAC service for safety and air quality

https://www.epa.gov/indoor-air-quality-iaq

✅ The Ideal Pro + DIY PTAC Routine

DIY Handles:

-

Filters

-

Coils (light cleaning)

-

Drain pans

-

Noise monitoring

-

Seasonal testing

Pros Handle:

-

Electrical testing

-

Heat element service

-

Refrigerant diagnostics

-

Motor replacement

-

Control board issues

Together, they create reliability.

🧠 Final Word: Smart Maintenance Isn’t About Pride

Calling a pro isn’t failure—it’s strategy.

The best PTAC owners know when to act—and when to step back.

Use DIY to stay ahead.

Use professionals to stay protected.

That balance keeps your PTAC quiet, efficient, and reliable for years.

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: Smart Sensors & IoT for PTAC Maintenance: What’s Worth It in 2026