Key Takeaways

-

Keep the line set short and straight to conserve energy.

-

Use the correct pipe size and bundle tightly for oil return.

-

Protect copper with UV-rated covers.

-

Slope the drain hose ¼ inch per foot to prevent backups.

-

Use a spring bender to create wide bends, which helps prevent kinks.

-

Pressure test with nitrogen and pull a 500-micron vacuum.

The Hidden Pipes That Decide Your Comfort

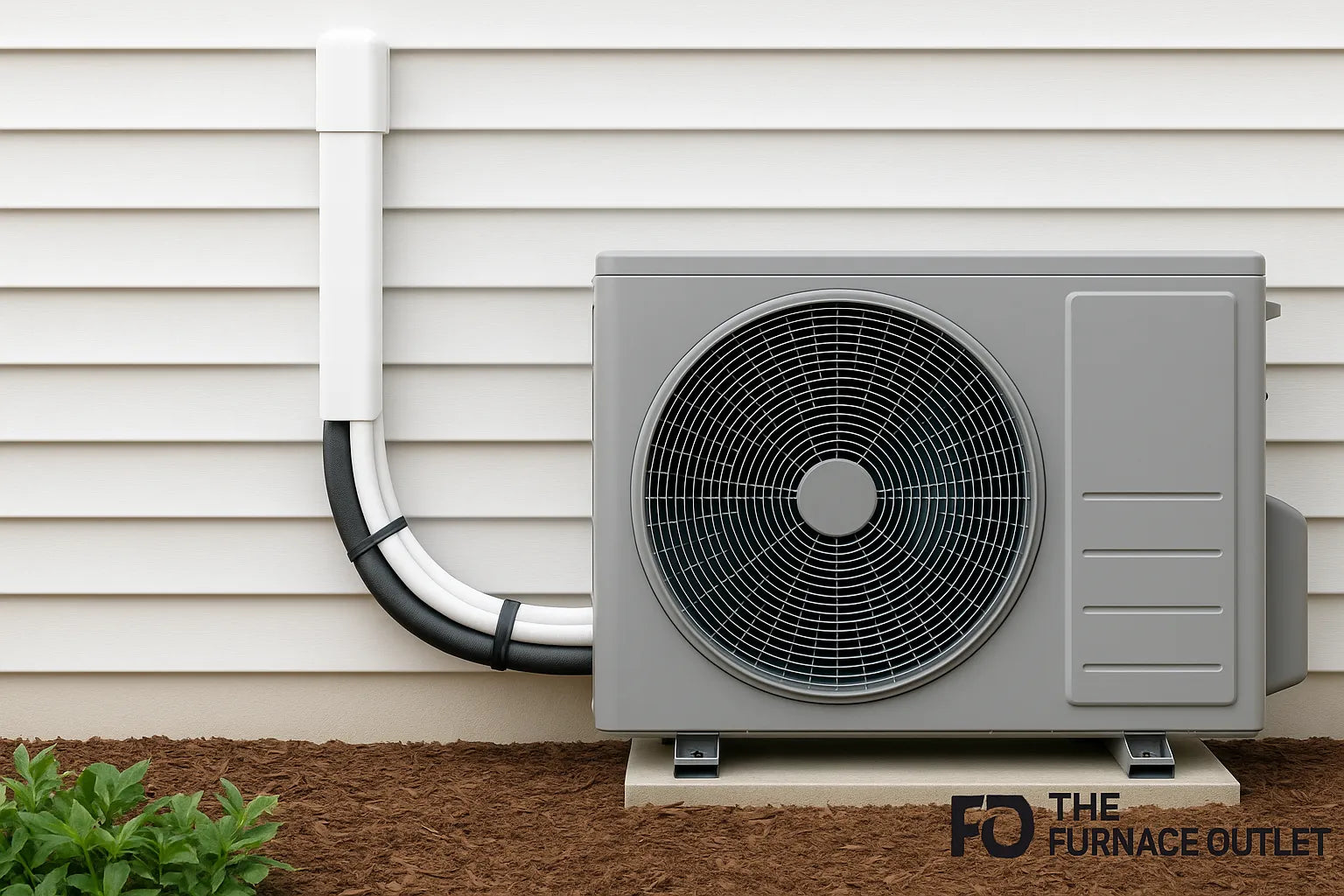

When you picture a mini‑split, you probably see the sleek wall head or the outdoor condenser. What you don’t see is the slim copper line‑set that shuttles refrigerant between them. If the piping is too long, badly bent, or kinked, the compressor works harder, energy bills rise, and comfort levels drop. U.S. sales of ductless systems have doubled since 2020, and today’s high‑SEER2, low‑GWP R‑32 models push even higher pressures through those lines, making tidy routing more important than ever. A well‑planned path also protects your siding, keeps landscaping neat, and saves technicians time on future service calls. In this guide, you’ll learn pro‑level routing practices, taught in plain language—so even a first‑time DIYer can understand why each step matters.

Need help visualizing your layout? Browse pre-charged mini-split systems

Plan the Straight‑Shot Path Before You Drill

Grab a tape measure and sketch the run from indoor head to condenser. Aim for the shortest, most direct route—every extra foot adds friction, and every 90‑degree bend can cost up to 3 % capacity. Place blue painter’s tape on the wall or soffit to visualize where the bundle will exit and enter. Check both sides of the wall for studs, plumbing, or wiring before drilling a 3‑in. hole. If obstacles force a detour, add sweeping elbows rather than tight turns.

Before you cut, scan the installation manual for the minimum and maximum line-set lengths; most residential units fall within the 10–50 ft window. Planning now avoids the heartbreak of trimming a pre‑charged line because it ended up two feet short. For step-by-step prep photos, see our DIY Easy-Pro Mini-Split Walk-Through.

Pick the Right Diameter and Keep the Bundle Tight

Mini‑split makers size suction and liquid lines to fractions of an inch. Using the wrong diameter throttles can cause refrigerant to overheat compressors and void warranties. Check the specification label—an 18,000 BTU head, for instance, often requires a ⅜-inch liquid line and a ⅝-inch suction line. Pair them with the factory‑specified insulation thickness (⅜‑in. wall is common). Tape the two copper pipes, the drain hose, and the control cable into a single bundle every 18 in. This prevents rattles in high winds and keeps the drain from sagging. Leave the bundle tails slightly staggered so flare nuts and grommets are easy to reach later.

Not sure what line set you need? Check complete line set kits

Protect Lines With Covers and UV‑Rated Insulation

Outdoor UV light causes rubber insulation to deteriorate into dust within two summers. Slide the bundle into a rigid PVC line‑hide or flexible UV‑rated conduit as soon as it leaves the wall. Most covers snap open for service and can be painted to match siding. At wall penetrations, insert a plastic sleeve and seal both ends with silicone to block rain, bugs, and humid air. Maintain at least six inches of clearance behind the condenser to prevent the cover from obstructing airflow.

In hurricane‑prone zones, add stainless‑steel clamps every three feet to stop wind whip. Proper protection doesn’t just look tidy—it can add five years to insulation life and preserve SEER2 ratings advertised on the box. For pictures of pro‑level exterior runs, check the photo gallery in our Outdoor Unit Placement Tips.

Slope the Drain Line So Water Never Backs Up

The condensate hose shares the same bundle, but it operates according to its own rule: gravity. Maintain a continuous downward slope of at least ¼ in. per foot from the indoor head to the outside. Even a 3 mm (⅛‑in.) uphill blip can send water back into the wall and ruin drywall or flooring If a downhill path isn’t possible, add a low‑wattage condensate pump inside the line. Keep the hose slightly offset from the suction line to prevent insulation from staying dry. Outside, terminate the hose two inches above grade and away from walkways to prevent algae stains. In freezing climates, route into a heated space or install heat tape to stop winter ice dams.

Need to lift condensate uphill? Explore condensate pump options

Make Bends Smooth No Kinks Allowed

Copper doesn’t like sharp corners. Use a spring bender or ratcheting lever tool to form gentle 90‑degree sweeps with a radius at least four times the pipe diameter. Kinking cuts the internal area and can starve refrigerant flow by 10 %—that’s the difference between a cool den and a muggy one on a 95°F Ohio afternoon. If the route demands multiple bends, space them six inches apart so the pipe isn’t forced into an S‑shape. Never straighten factory coils by hand; unwind them slowly on the ground to avoid flattening. When you must shorten a pre‑charged set, save three extra inches for a clean flare and deburr the cut so metal shavings don’t migrate into the compressor oil.

Prevent kinks with the right tools. See flare kits and benders

Flare, Torque, and Pressure‑Test Every Connection

Mini‑split systems rely on flare fittings—no brazing required. Cut square, ream inside edges, then create a 45‑degree flare using a clutch‑type flaring block. A drop of POE oil on the seat helps seal. Torque the nut to the chart value (e.g., 26 ft‑lb for ⅜‑in. line). Once all joints are tight, pressurize the system with dry nitrogen to 300 psi and monitor the gauge for ten minutes. A falling needle means a leak—fix it before opening refrigerant valves. Finally, pull a vacuum to 500 microns and hold for 15 minutes. Skipping any of these steps is the fastest way to lose those shiny efficiency numbers printed on the brochure.

Seal it right the first time. Use our flaring and vacuum tools

Keep Power and Signal Wires Safe and Separate

Line‑set routing isn’t only about copper. Control cables carry 24 V signals that hate interference from 230 V power wires. Run them in separate sheaths or use shielded cable rated sunlight‑resistant for outdoor use. NEC code requires a dedicated disconnect box to be located within sight of the condenser and a weatherproof whip to be connected to the unit’s terminals. Follow the color diagram exactly—swap L1 and L2 on an inverter board, and the compressor may not start. In snowy states, mount the disconnect 4 ft above grade so it stays accessible when drifts pile up. For a refresher on safe breaker sizing and permit requirements, refer to the Electrical & Code section in our main Installation Guide.

Document Your Work and Re‑Check Manufacturer Limits

Before insulating the final foot, snap photos of every joint, note the exact line-set length, added refrigerant weight (if any), and final test pressures. This record confirms that the system was installed to specification and speeds up any warranty claim. Tape a copy inside the condenser access panel and save a digital copy in your phone. Finally, open the manual one last time to verify that the total length, vertical rise, and bend count fall within limits. A five‑minute double‑check can spare you a $1 000 compressor replacement later.

Ensure code-compliant connections. Browse mini-split electrical accessories

Frequently Asked Questions

Q1. How long can a mini‑split line‑set be?

Most residential systems allow 15–50 ft. Check the manual—exceeding limits needs extra refrigerant and may void the warranty.

Q2. Can I hide the line‑set inside a wall?

Yes, but use a fire‑rated chase, keep bends gentle, and leave an access panel at every flare connection for service.

Q3. What if my drain line must run uphill?

Install a mini-split condensate pump rated for at least 15 feet of lift and route its discharge to a safe drain point.

Q4. Do I need special insulation for cold climates?

Use ⅜‑in. or thicker closed‑cell insulation, rated –40 °F to 221 °F, and wrap with UV‑resistant tape or cover.

Q5. Will routing mistakes also affect heating performance?

Absolutely—restricted refrigerant flow affects both cooling and heating capacity, especially in low-temperature heat-pump mode.