🏠 1. Introduction — Why Maintenance Matters More Than Ever

When I (Jake) first switched to an R-32 condenser, I was focused on performance. I wanted cleaner air, better efficiency, and quieter operation than my old R-410A system. What I didn’t realize at first was how much maintenance mattered — not just for keeping the system running, but for preserving that new-performance feeling year after year.

By my second season, I’d learned that a clean, well-maintained condenser doesn’t just cool faster — it saves me hundreds of dollars annually in energy costs, reduces noise, and extends the system’s life span. And because R-32 systems use a low-GWP refrigerant, maintaining proper airflow and pressure is even more critical for both efficiency and safety.

This guide breaks down everything I’ve learned — from the simple monthly tasks any homeowner can do, to the annual professional checks that keep your R-32 condenser running like new for 15 years or more.

🌬️ 2. Understanding How R-32 Systems Stay Efficient

R-32 is known for its high heat transfer efficiency — it moves heat more effectively than older refrigerants. But that efficiency depends on clean airflow and stable refrigerant pressure. Even a thin film of dirt on your condenser coils can make your compressor work 10–15% harder.

Let’s look at what that means in everyday terms:

| Issue | Efficiency Loss | What It Causes |

|---|---|---|

| Dirty condenser coil | 10–15% | Higher power draw, reduced cooling |

| Blocked airflow | 15–25% | Overheating compressor |

| Low refrigerant charge | 10–20% | Poor temperature control |

| Clogged filter/dust | 5–10% | Reduced air circulation |

📘 Reference: Daikin – The Benefits of R-32 Technology

Because R-32 systems use less refrigerant volume than R-410A — about 70% less — there’s less margin for error. Keeping coils, lines, and fans clean ensures that the refrigerant can flow smoothly and dissipate heat properly.

🧽 3. Monthly Maintenance Tasks — The Easy Wins

You don’t need to be a technician to keep your condenser in shape. Once a month, take 10 minutes to do these five simple checks.

✅ 1. Clear Away Debris

Use your hands or a soft brush to remove:

-

Leaves, twigs, or grass around the base

-

Cobwebs near coils or louvers

-

Mulch buildup at the base pad

Keep a 2-foot clearance on all sides so your unit can breathe freely.

✅ 2. Inspect Coil Fins

Over time, fins can bend from pets, lawn mowers, or debris. Bent fins restrict airflow.

-

Use a fin comb or butter knife to gently straighten them.

-

Don’t apply force — these are delicate aluminum strips.

✅ 3. Check Refrigerant Line Insulation

The suction line (larger copper pipe) should have a foam insulation sleeve. If you see cracks or gaps, replace it with new pipe insulation to prevent heat loss.

✅ 4. Wipe the Exterior

Dust and grime can attract moisture and corrosion. Use a damp microfiber cloth to wipe down the cabinet.

✅ 5. Listen and Observe

When your system runs, step outside and listen.

-

Any new buzzing, rattling, or humming could indicate loose screws or a fan imbalance.

-

Vibrations could signal a pad that’s shifted out of level.

Jake’s Tip:

“My condenser runs smoother when I treat it like part of my landscaping — clean, clear, and visible.”

📗 Reference: Energy.gov – Maintaining Your Air Conditioner

🌸 4. Seasonal Maintenance — Spring Start-Up & Fall Shut-Down

You only need to do a deep check twice a year — once before cooling season and once before winter. Here’s what I do.

🌼 Spring Start-Up Checklist

-

Remove cover if you used one in winter (never cover sides, just the top).

-

Inspect the coils for dirt, leaves, and twigs.

-

Clean coils using a foaming coil cleaner or mild detergent and hose rinse.

-

Check the electrical disconnect box for corrosion or insects.

-

Inspect fan blades for debris or cracks.

-

Power on the system and listen for smooth startup.

Jake’s Note:

“The first spring after installing my R-32 condenser, I forgot to check for nesting debris — the airflow dropped 20% until I cleaned it out.”

🍂 Fall Shut-Down Checklist

-

Turn thermostat to ‘off’ before winter.

-

Hose down the unit to remove pollen, dust, and leaves.

-

Trim shrubs at least 2–3 feet away from the coils.

-

Cover only the top fan section (never wrap the sides).

-

Check for corrosion or paint wear and touch up if needed.

📘 Reference: EnergyStar – Seasonal HVAC Maintenance Tips

⚙️ 5. Annual Maintenance — What to Expect from Your Technician

At least once a year, preferably in spring, schedule a professional R-32-certified technician to inspect your system. This is critical not just for performance, but also for A2L refrigerant safety compliance.

🔧 Professional Technician Tasks

-

Check refrigerant charge and pressure: Ensures cooling efficiency and prevents compressor stress.

-

Perform nitrogen leak test: R-32 is stable, but small leaks can cause capacity loss.

-

Test electrical components: Check capacitor, contactor, and wiring.

-

Clean and level base pad: Prevent vibration and uneven drainage.

-

Check fan motor amperage and bearings.

-

Inspect safety labeling and A2L compliance tags.

📗 Reference: ASHRAE – Refrigeration System Maintenance Best Practices

Jake’s Tip:

“Ask your tech to record pressure readings and subcooling data — you’ll see small performance changes before they become problems.”

🧼 6. Cleaning Condenser Coils — Step-by-Step Guide

This is the single most effective thing you can do for your system’s performance.

🪣 You’ll Need:

-

Garden hose (gentle pressure)

-

Coil cleaner (non-acidic)

-

Soft brush or microfiber towel

-

Screwdriver (for fan grille removal)

Step-by-Step:

-

Power off the system at the disconnect switch.

-

Remove top grille if necessary for better access.

-

Spray coils from inside-out, not outside-in (push debris outward).

-

Apply coil cleaner and let it foam for 10 minutes.

-

Rinse thoroughly until water runs clear.

-

Reattach fan grille and power back on.

Avoid pressure washers — they can bend coil fins and force dirt deeper.

Jake’s Tip:

“I schedule coil cleaning every spring before the first 90°F week. My energy use drops 10% almost immediately.”

📘 Reference: HVAC School – Coil Cleaning Methods

🔇 7. Noise & Vibration Check

Even quiet systems can get noisy if something shifts or loosens over time.

Common Causes:

-

Loose screws or fan guard bolts

-

Uneven concrete pad

-

Vibrating refrigerant lines touching walls

Fixes:

-

Tighten screws gently with a socket wrench.

-

Place rubber isolation pads under unit corners.

-

Re-level the pad using gravel or shims if needed.

-

If noise persists, check for fan motor wear or compressor mounts.

Jake’s Experience:

“After a season of rain, my pad shifted just half an inch — and the hum increased noticeably. Re-leveling it fixed everything.”

📗 Reference: Trane Residential – Reducing AC Noise

🧯 8. Safety & Handling of R-32 (A2L Refrigerant)

R-32 is designated A2L, meaning it’s mildly flammable under specific conditions but safe in outdoor, ventilated systems when maintained correctly.

Safety Do’s:

-

Always maintain good airflow around the condenser.

-

Never cover or seal the sides of the unit.

-

Keep flammable materials (grills, gasoline, paint thinner) at least 5 ft away.

-

Make sure technicians are R-32 trained and carry proper recovery tools.

-

Keep labels visible — “Contains R-32 (A2L)” should be readable.

Safety Don’ts:

-

Don’t open refrigerant lines yourself.

-

Don’t use electrical equipment near refrigerant leaks.

-

Don’t install or move the unit without professional help.

📘 Reference: EPA – Safe Handling of A2L Refrigerants

Jake’s Tip:

“R-32 is efficient and eco-friendly. As long as you let airflow and professionals handle the sealed system, it’s safer than your propane grill.”

🧾 9. Keep a Maintenance Log (and Protect Your Warranty)

Most manufacturers require documented maintenance for warranty claims. Keeping simple records ensures coverage and helps track performance over time.

| Task | Frequency | Who Performs | Notes |

|---|---|---|---|

| Coil cleaning | Every spring | Homeowner | Record date and photo |

| Refrigerant check | Annually | Technician | Log psi and subcooling |

| Electrical inspection | Annually | Technician | Verify capacitor voltage |

| Pad leveling | 1–2 years | Homeowner | Check vibration |

| Label verification | Annually | Technician | Confirm A2L signage |

Jake’s Habit:

“I take a photo of my maintenance log each spring and email it to myself — easy proof for warranty or resale.”

📘 Reference: EnergyStar – Maintaining Your AC Warranty

🌤️ 10. Long-Term Maintenance (5–10 Year Outlook)

Even the best systems age. Staying proactive helps your condenser reach (and exceed) its design lifespan.

Every 2–3 Years

-

Inspect contactors and relays for pitting.

-

Replace insulation on refrigerant lines.

-

Check fan blade balance.

Every 5–7 Years

-

Replace capacitor and contactor preventively.

-

Inspect compressor mounts.

-

Clean electrical connections with dielectric grease.

Every 10 Years

-

Repaint cabinet to prevent corrosion.

-

Test surge protector or replace if power surges are frequent.

-

Consider professional coil deep cleaning or replacement if corrosion begins.

📗 Reference: EnergyStar – Extending HVAC Life

⚡ 11. Troubleshooting Common Issues

Sometimes small symptoms reveal big issues — here’s what to watch for.

| Problem | Possible Cause | Solution |

|---|---|---|

| Unit won’t start | Tripped breaker or contactor failure | Check breaker, call tech |

| Weak cooling | Dirty coils or low refrigerant | Clean coils, schedule recharge |

| Loud buzzing | Electrical contactor issue | Replace contactor |

| Clicking noise | Fan blade obstruction | Inspect and clear debris |

| Water pooling | Uneven pad or drain block | Re-level or clear drain |

| Ice on coils | Restricted airflow | Clean coils and filters |

Jake’s Tip:

“If you see frost or hear a high-pitched whine, shut it off and call a pro — that’s a refrigerant imbalance warning.”

🌿 12. Landscaping & Airflow Management

Good airflow keeps your system cool and efficient. Landscaping around the unit can either help or hurt.

Do:

-

Keep shrubs 2–3 feet away from all sides.

-

Use gravel or pavers instead of mulch at the base.

-

Plant low-growing evergreens for aesthetics and protection.

-

Leave clear vertical space for exhaust (at least 5 ft above).

Don’t:

-

Let vines or tall plants touch coils.

-

Stack garden tools or furniture nearby.

-

Block discharge airflow with fences or walls.

Jake’s Setup:

“I used small boxwoods and gravel — it hides the unit but still breathes perfectly.”

📘 Reference: Energy.gov – Landscaping for Energy Efficiency

🧠 13. Jake’s Year-Round Maintenance Schedule

Here’s the checklist I follow — feel free to copy it into your own planner.

🗓️ March

-

Uncover condenser and rinse coils.

-

Inspect fins and insulation.

-

Clear debris and check pad leveling.

🗓️ May

-

Schedule professional service.

-

Verify refrigerant charge and electrical checks.

🗓️ July

-

Mid-summer inspection: coil rinse and noise check.

-

Ensure shrubs haven’t grown too close.

🗓️ October

-

Fall clean-up: remove leaves, rinse, and partial cover.

-

Check electrical disconnect for rust.

🗓️ December

-

After storms: quick visual check for ice, snow, or debris.

Jake’s Result:

“After following this plan for three years, my R-32 system still performs like the day it was installed — quiet, efficient, and problem-free.”

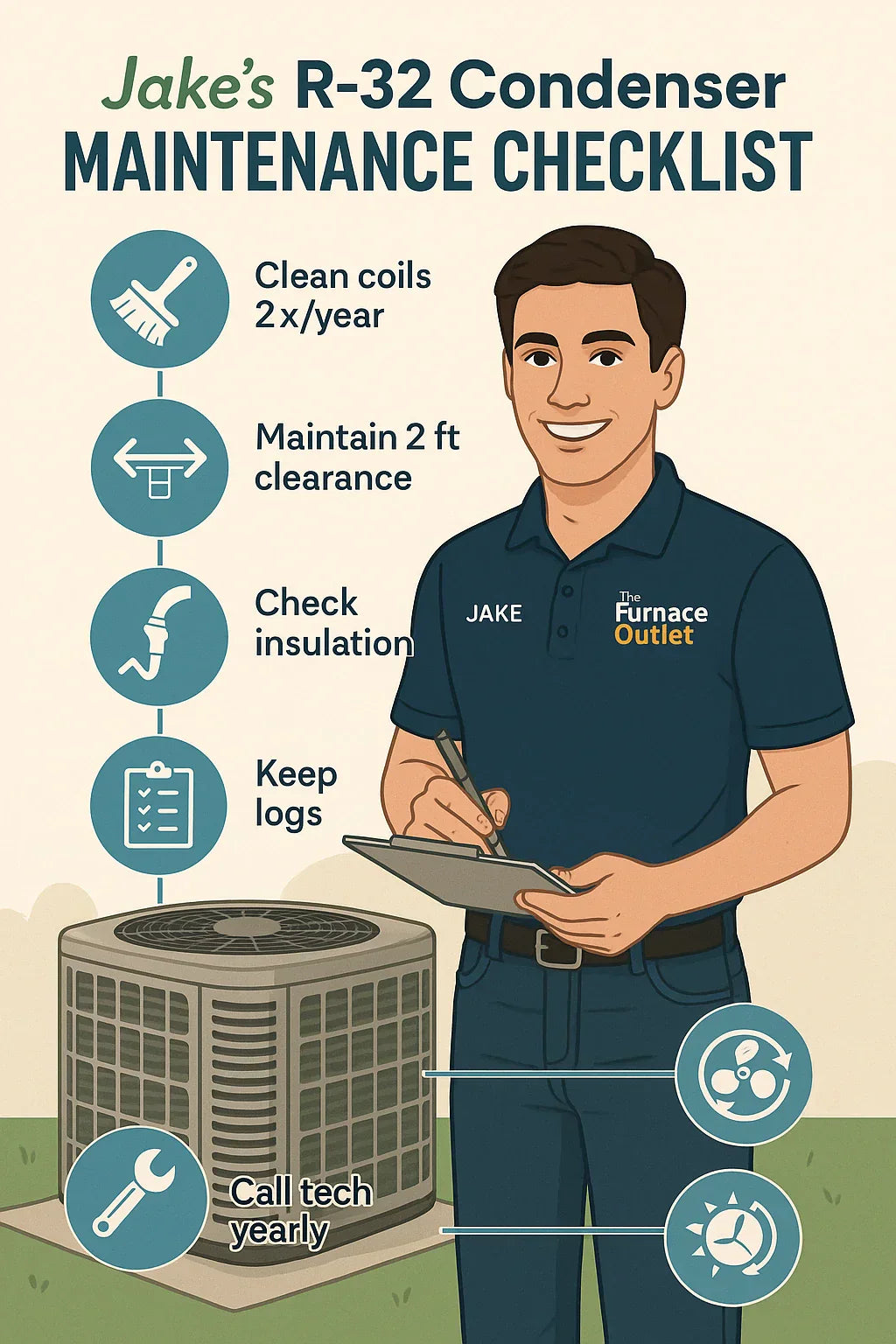

🖼️ 15. Matching Visual Concept

Title: “Jake’s R-32 Condenser Maintenance Checklist”

Design Concept:

Jake stands next to his R-32 condenser with illustrated labels:

-

“Clean coils 2x/year”

-

“Maintain 2 ft clearance”

-

“Check insulation”

-

“Keep logs”

-

“Call tech yearly”

Icons:

-

🧽 Cleaning brush

-

💨 Fan airflow

-

⚡ Wrench

-

📋 Clipboard

-

🌦️ Seasonal arrows

Colors: eco-green, steel blue, and neutral beige background for a clean technical look.

🌎 16. Final Takeaway — A Little Care Goes a Long Way

R-32 condensers are built for the future — high efficiency, low environmental impact, and quiet operation. But like any high-performance system, they rely on routine attention to stay that way.

By taking a few minutes each month to clean, inspect, and log your maintenance, you’ll enjoy:

-

Lower utility bills

-

More consistent comfort

-

Quieter operation

-

A system that easily lasts 15–20 years

And perhaps the best part? You’ll understand your equipment better than ever — and spot issues before they become costly.

As Jake would say:

“If you can keep your yard tidy, you can keep your R-32 condenser in top shape. A little time each season keeps it running like new — quietly, efficiently, and ready for the future.”

In the next topic we will know more about: Troubleshooting Tips: What to Do If Your R-32 Condenser Isn’t Cooling Properly