Maintenance Guide: How to Keep Your 3 Ton R-32 System Running Like New

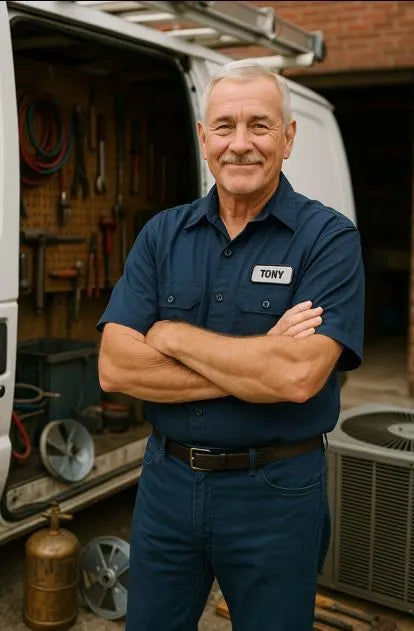

Tony Marino’s Year-Round Checklist for Long-Term Comfort, Efficiency & Peace of Mind

🧠 Tony’s Intro: “Most Failures Aren’t Mechanical — They’re Maintenance”

You wouldn’t run your truck for 10,000 miles without an oil change.

Your air conditioner’s no different.

I’ve pulled compressors out of five-year-old systems that looked twenty years old — and I’ve seen twenty-year-old units still running strong because the homeowner stayed on top of maintenance.

Here’s the truth:

Maintenance doesn’t cost money — neglect does.

If you learn a few basics and stay consistent, your 3 Ton R-32 AC will stay efficient, quiet, and problem-free for decades.

This guide is exactly how I keep customer systems humming after every install.

⚙️ 1. Why Maintenance Matters More for R-32 Systems

R-32 runs cooler and cleaner than older refrigerants, but it’s also more precise. Small issues — airflow, debris, moisture — affect it faster.

| Issue | What It Causes |

|---|---|

| Dirty coil | Higher pressure → higher bills |

| Low airflow | Frozen coil → compressor strain |

| Clogged drain | Water overflow → mold |

| Wrong charge | Poor cooling → reduced life |

👉 Tony’s Rule:

“R-32 is like a performance engine — runs great if tuned, but don’t skip oil changes.”

🧊 2. Seasonal Maintenance Schedule

(Energy Star Maintenance Checklist)

| Season | Tasks | Tony’s Tip |

|---|---|---|

| Spring (Start-up) | Clean coils, change filter, test thermostat, clear drain | “Tune it before the heat hits.” |

| Summer | Monitor temps, rinse condenser fins, check fan noise | “Mid-season rinse keeps head pressure low.” |

| Fall (Shut-down) | Replace filter, vacuum drain, inspect ducts | “Prep now = no mold later.” |

| Winter | Cover the top of the condenser (not sides), and power off the breaker | “Protect it, don’t smother it.” |

🧼 3. Filter Care — Your First Line of Defense

A dirty filter cuts airflow and wrecks efficiency.

| Filter Type | Replace Every | Efficiency |

|---|---|---|

| Fiberglass | 30 days | 20–30 % |

| Pleated MERV 8–11 | 60–90 days | 60–80 % |

| HEPA (MERV 13+) | 90 days | 90 % + – needs strong fan |

👉 Tony’s Tip:

Mark your phone calendar the day you change it. If it’s grey before 30 days, check duct leaks or pet dander.

🧰 4. Coil Cleaning — Where Efficiency Lives or Dies

Dirty coils are the #1 cause of poor cooling and high bills.

Outdoor Coil

-

Turn off the breaker.

-

Remove the top grill carefully.

-

Hose gently from inside out — not high pressure.

-

For caked dirt, use coil cleaner (non-acid).

Indoor Evaporator Coil

-

Access through the service panel.

-

Spray with no-rinse foam cleaner.

-

Replace the filter afterward.

👉 Tony’s Warning:

Don’t use a pressure washer. I’ve seen fins folded like aluminum foil.

💧 5. Condensate Drain Care

Blocked drains cause leaks, musty odors, and safety-switch shutdowns.

(Energy Star Condensate Maintenance Guide)

Steps:

-

Locate the drain PVC near the air handler.

-

Pour one cup of white vinegar every 3 months.

-

Flush with hot water if sluggish.

-

Check float switch wiring.

👉 Tony’s Tip:

Add a clear PVC trap so you can see clogs before they happen.

🌬️ 6. Check Airflow and Registers

Airflow = system life.

Your 3 Ton system needs about 1,200 CFM.

-

Open all supply vents — never close more than 10%.

-

Vacuum registers every season.

-

Verify return grilles aren’t blocked by furniture.

👉 Tony’s Note:

If rooms feel uneven, you may need balancing — not a bigger AC.

🔩 7. Inspect Refrigerant Lines and Insulation

Look for oil stains or loose insulation on the suction line.

-

Replace damaged foam sleeves.

-

Secure lines every 4 ft.

-

Keep them out of direct sunlight.

(EPA Refrigerant Handling Safety)

👉 Tony’s Take:

Insulation keeps refrigerant cold — lose that, and you lose efficiency.

⚡ 8. Electrical Connections and Controls

Loose wires = voltage drops and short cycles.

Have a pro check these yearly:

-

Contactor points (pitting)

-

Capacitor µF rating

-

Thermostat wiring tightness

-

Disconnect box corrosion

👉 Tony’s Tip:

Tighten low-voltage terminals with power off — fingertip snug only.

🔊 9. Noise Inspection = Health Inspection

| Sound | Possible Cause | Fix |

|---|---|---|

| Buzz | Contactor coil | Replace |

| Rattle | Panel screws | Tighten |

| Hiss | Refrigerant leak | Pro service |

| Gurgle | Drain line | Flush |

👉 Tony’s Tip:

A quiet AC is a healthy AC. New noises are your early warning system.

🧯 10. Safety Steps for DIY Checks

-

Shut off the breaker before opening panels.

-

Never touch refrigerant lines barehanded (can cause frostbite).

-

Wear gloves and eye protection when cleaning coils.

-

Leave refrigerant or capacitor work to certified techs.

👉 Tony’s Rule:

If you need a gauge to fix it, call a pro.

🧩 11. Professional Service Tasks

During annual tune-ups, your technician should:

-

Measure superheat/subcooling.

-

Verify charge weight matches spec.

-

Test amp draw on the compressor and fan.

-

Record static pressure and temp split.

-

Inspect the drain pan, float switch, and coils.

👉 Tony’s Tip:

Ask for a written report — not just “looks good.”

💡 12. Energy Efficiency Maintenance Habits

-

Replace filter regularly (+5–10 % efficiency).

-

Shade outdoor unit (+3 %).

-

Clean coils (+5 %).

-

Seal duct leaks (+15 %).

-

Maintain proper charge (+10 %).

(Energy.gov Efficiency Checklist)

👉 Tony’s Take:

These add up to 25–30 % savings — maintenance is money.

🧱 13. Humidity and Dehumidification Check

R-32 systems excel at moisture removal.

If humidity rises above 55 % indoors:

-

Clean the coil and filter.

-

Check blower speed (too high = poor dehumid).

-

Verify thermostat’s dehumidify mode (if smart).

(Energy Star Humidity Control Guide)

👉 Tony’s Tip:

Comfort = temperature + humidity. Fix both.

💧 14. Drain Pan and Float Switch Care

-

Inspect the pan for rust each spring.

-

Test the float switch by lifting the arm — the system should shut off.

-

Keep the secondary drain pipe clear.

👉 Tony’s Tip:

Add a pan alarm sensor for peace of mind — $30 can save a ceiling.

🧾 15. Coil Fin Straightening and Protection

Bent fins block airflow and raise pressure.

Use a coil fin comb once a year.

👉 Tony’s Trick:

Spray fins with coil protector after cleaning — it resists corrosion from salt air.

🌬️ 16. Blower and Fan Maintenance

-

Remove the blower wheel every 2 years for a deep clean.

-

Lubricate motor if non-sealed (type PSC).

-

Check fan balance with the vibration meter app (optional).

👉 Tony’s Tip:

A dirty blower steals airflow quietly — until your bill shouts at you.

🧱 17. Thermostat Calibration

Compare reading with a reliable thermometer.

If it’s off by 2°F +, recalibrate or replace.

Smart thermostats update firmware — check Wi-Fi monthly.

👉 Tony’s Tip:

If your system short-cycles, thermostat placement may be wrong — avoid sunlight and supply air drafts.

🧩 18. Duct Inspection and Insulation

Every 3 years, have the ducts pressure-tested.

| Leak Rate | Fix Urgency |

|---|---|

| <10 % | Normal |

| 10–20 % | Seal soon |

| >25 % | Replace sections |

👉 Tony’s Tip:

Insulate attic runs to R-8 minimum — you’ll gain cooling capacity for free.

⚡ 19. Check System Startup Each Spring

-

Breaker ON

-

Thermostat set to COOL 75°F

-

Observe fan direction (outward airflow)

-

Measure temp split (16–22°F ideal)

👉 Tony’s Tip:

Keep a log book of temperatures, amps, and pressures — small changes predict big issues early.

🧱 20. Warranty Protection Through Maintenance

Goodman requires proof of routine service for 10-year coverage.

Keep receipts and annual reports.

👉 Tony’s Rule:

Paperwork protects your wallet as much as your system.

🧩 21. Signs It’s Time for a Pro Check

Call a technician if:

-

The air feels warm, but the compressor runs.

-

Frost on the coil or lines.

-

Energy bill spikes 10 % + without heat wave.

-

Unit cycles more than 6× per hour.

👉 Tony’s Advice:

Don’t wait for total failure. $150 in diagnostics can save a $1,500 compressor.

🧊 22. Environmental Care and R-32 Safety

Store R-32 cylinders upright, in shade, < 125°F.

Recycle old refrigerant legally — EPA Section 608 required.

👉 Tony’s Tip:

R-32 is reclaimable — don’t vent it or you’ll get fined and waste money.

🧾 23. Long-Term Performance Goals

| Year | What to Do | Result |

|---|---|---|

| 1–3 | Basic cleaning & filters | Maintain efficiency |

| 4–6 | Deep coil & blower service | Restore capacity |

| 7–10 | Replace contactors & caps | Prevent failure |

| 10 + | Evaluate ducts & thermostat | Optimize comfort |

👉 Tony’s Take:

Treat it like a 25-year machine — because that’s what it can be.

🏁 24. Tony’s Final Word

Your 3 Ton R-32 system is built for efficiency, quiet operation, and longevity — if you give it a little attention every season.

Think of maintenance as a partnership with your AC. You do your half, it’ll keep your home comfortable for 20 years or more.

👉 Tony’s Bottom Line:

“Clean filters, clear coils, and steady airflow — that’s the recipe for a system that never quits.”

Next, we will get the idea of the warranty and lifespan of your 3 Ton R-32 system.