🔧 Introduction: Gas Pressure Is the Heartbeat of the Furnace

Most installers think gas pressure setup is complicated.

It’s not — if you know what you’re doing.

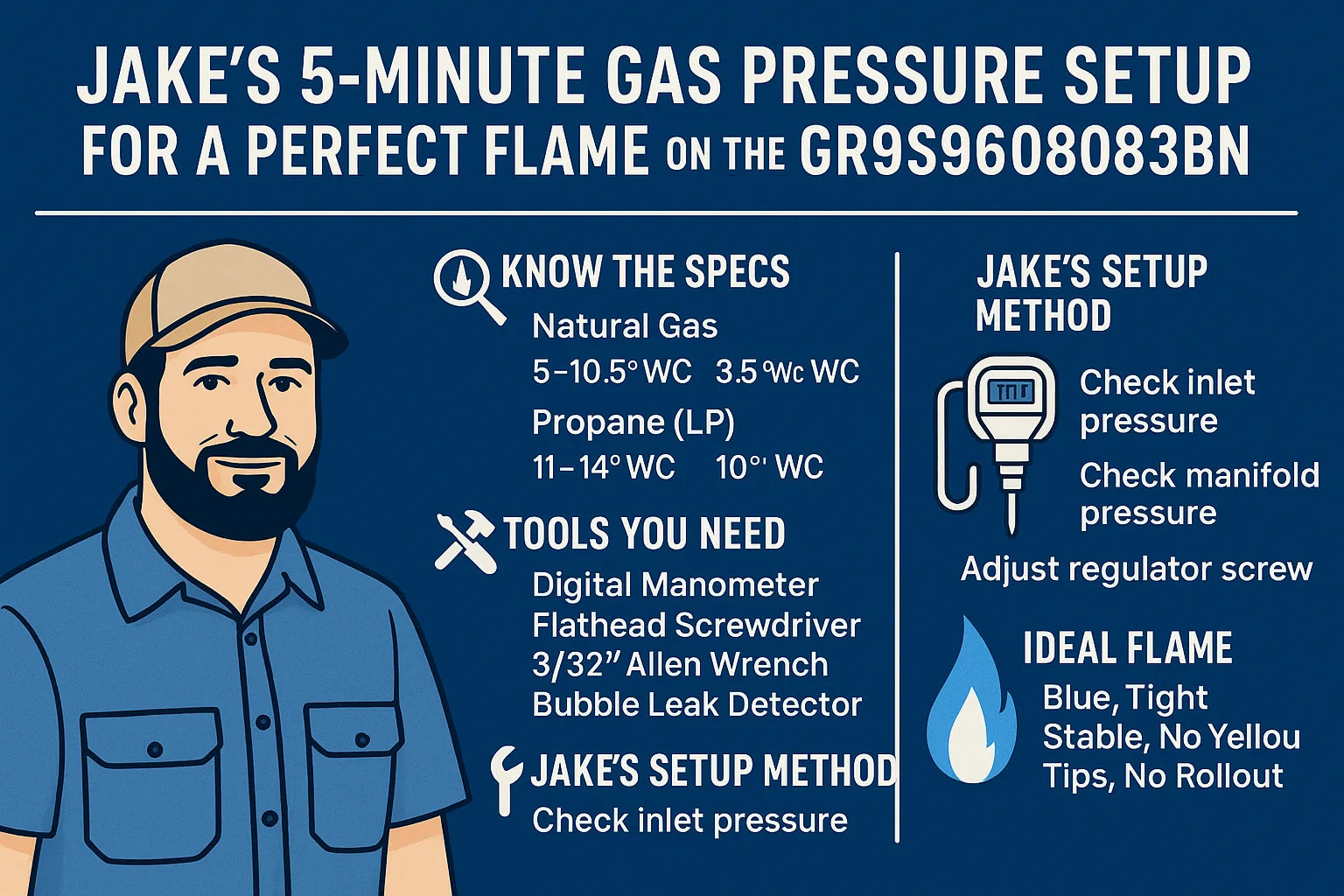

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

On a Goodman GR9S960803BN (the 80,000 BTU, 96% AFUE single-stage furnace), the difference between:

-

a smooth, clean, blue flame

and -

a noisy, yellow-tipped, unstable, delayed burner

comes down to two pressures:

-

Inlet pressure (what the utility delivers)

-

Manifold pressure (what the gas valve delivers to the burners)

If either is wrong, the furnace:

-

ignites hard

-

rolls out

-

makes rumbling noises

-

produces soot

-

runs inefficiently

-

overheats

-

or wastes fuel

Jake’s 5-minute setup method eliminates all of that.

This is the exact tuning process I’ve used for two decades to ensure Goodman furnaces fire like a jet engine — clean, quiet, and perfect.

🔍 1. Before You Touch the Gas Valve, Know Goodman’s Specs

Every furnace has manufacturer specs.

These are non-negotiable.

For the Goodman GR9S960803BN, the gas valve pressures must be:

Natural Gas:

-

Inlet pressure: 5" to 10.5" WC

-

Manifold pressure: 3.5" WC (± 0.1")

Propane (LP):

-

Inlet pressure: 11" to 14" WC

-

Manifold pressure: 10" WC (± 0.3")

External verified link:

• Goodman GM9S/GR9S Installation Manual

https://www.goodmanmfg.com

If your manifold pressure isn’t exactly right, you will not get a stable flame.

🧰 2. Tools Jake Uses for Perfect Gas Pressure Setup

You only need three tools:

✔ Digital Manometer

Accuracy beats analog every time.

External verified link:

• Fieldpiece Digital Manometer Specs

https://www.fieldpiece.com

✔ Flathead Screwdriver

For gas valve adjustment.

✔ 3/32" Allen Wrench

For opening pressure taps.

✔ Bubble Leak Detector

Never rely on smell.

External verified link:

• Oatey Gas Leak Detector

https://www.oatey.com

That’s it.

Three tools, one valve, five minutes.

⚠️ 3. Safety Rules Jake Follows Before Any Gas Adjustment

Gas tuning is safe — if you do it right.

Here are my non-negotiables:

-

Furnace gas supply must be leak-free

-

Shutoff valve must be accessible

-

Room must be well-ventilated

-

No smoking or sparks

-

Never remove the gas valve regulator cover completely

-

Always use counterforce when turning the adjustment screw

-

Never overtighten the regulator

And most importantly:

If inlet pressure is out of spec, STOP. Don't adjust the valve to compensate. Fix the supply line.

🔩 4. Jake’s 5-Minute Setup Method (The Exact Steps)

Here is the step-by-step tuning method that delivers a perfect flame every time.

🟦 STEP 1 — Check Static Inlet Pressure (Appliances Off)

Turn off:

-

furnace

-

water heater

-

stove

-

gas dryer

You want to measure the utility pressure before any gas flow begins.

Connect the manometer to the inlet pressure tap on the gas valve.

The display should read:

-

Natural gas: 5"–10.5" WC

-

Propane: 11"–14" WC

If it doesn’t?

Your problem isn’t the furnace — it’s:

-

supply undersizing

-

regulator failure

-

utility drop issues

-

sediment trap blockage

-

kinked flex line

Fix inlet pressure before going any further.

🟧 STEP 2 — Check Dynamic Inlet Pressure (Appliances On)

Turn on:

-

furnace

-

water heater

-

stove burners

-

any other gas appliances

This simulates maximum load.

Dynamic inlet pressure must stay above:

-

Natural gas: 4.5" WC

-

Propane: 10" WC

If it drops too low under load, the furnace will:

-

flutter

-

ignite poorly

-

roll out flames

-

trip on flame failure

Fix supply pressure before continuing.

🟩 STEP 3 — Switch Manometer to Manifold Tap

Remove the tube from the inlet tap and move it to the manifold pressure tap.

This measures the pressure the gas valve sends to the burners.

Make sure the cap stays attached to the inlet tap during testing.

🟥 STEP 4 — Fire the Furnace on Heat Mode

Set the furnace to a W call (heat) and let it run for 1–2 minutes.

This warms the heat exchanger and stabilizes gas flow.

The manometer should now read:

Natural Gas Goodman GR9S960803BN: 3.5" WC

Propane Mode: 10" WC

If the pressure is correct — stop here.

You’re done.

If it’s not, continue to Step 5.

🟪 STEP 5 — Adjust the Regulator (Tiny Turns Only)

Use a flathead screwdriver.

Turn the gas valve adjustment screw:

🔼 Clockwise → Increase manifold pressure

🔽 Counterclockwise → Decrease manifold pressure

Only turn 1/16" at a time.

After each adjustment:

-

wait 10 seconds

-

recheck the reading

Your goal:

Hold manifold pressure EXACTLY at 3.5" WC (natural) or 10" WC (LP)

Do NOT exceed ±0.1" WC tolerance.

If you cannot hold pressure within tolerance?

The valve is bad. Replace it.

Never force a regulator to compensate for bad supply pressure.

🔥 5. Jake’s Flame Verification Checklist (You MUST Check This)

Setting gas pressure is one thing.

Verifying the flame is the REAL test.

When properly tuned, a Goodman GR9S flame should be:

✔ Blue

✔ Tight

✔ Stable

✔ No jumping

✔ No yellow tips

✔ No rollout

✔ Even across all burners

Yellow flame = incomplete combustion

Jumping flame = draft or pressure issue

Lazy flame = low input

Noise = overfiring

A perfectly tuned furnace looks like a row of jet engines.

🧪 6. The Combustion Air Equation — Where Most Techs Mess Up

Even correct gas pressure can produce a bad flame if the combustion air path is blocked.

Jake checks:

-

intake pipe for obstructions

-

correct slope

-

elbow count

-

snow blockage

-

cracked PVC

-

dirty burner orifices

-

clogged crossover ports

-

inducer RPM

-

pressure switch performance

External verified link:

• NFPA 54 – Combustion Air Requirements

https://www.nfpa.org

If combustion air isn’t correct, flame won’t be either.

🧼 7. Burner Maintenance (Do This Before Adjusting Pressure)

Burners must be clean BEFORE setting gas pressure.

Jake's cleaning steps:

✔ Remove burners

✔ Blow out dust & rust

✔ Clean crossover ports

✔ Clean orifices with compressed air

✔ Wipe burner faces gently

Dirty burners produce:

-

delayed ignition

-

uneven flame

-

noisy ignition

-

flame lift

-

yellow coloration

NEVER tune gas pressures on a dirty burner.

🔄 8. After Tune-Up: Jake’s Full System Verification

After gas pressure is dialed in, I perform:

1. Temperature Rise Test

GR9S960803BN recommended:

35°F–65°F

External verified link:

• Goodman Furnace Temperature Rise Specs

https://www.goodmanmfg.com

High temp rise = airflow problem

Low temp rise = underfiring

2. Static Pressure Test

Goal:

≤ 0.5" WC total external static

High static = airflow restrictions → flame instability

3. CO Measurement (Optional but Recommended)

CO in flue should be:

-

NG: < 100 ppm

-

LP: < 150 ppm

Low CO = clean, efficient flame

High CO = bad mix or blocked exchanger

4. Pressure Switch Stability

Switch must hold steady pressure during:

-

inducer startup

-

burner ignition

-

flame stabilization

A fluttering pressure switch means draft issue, not gas issue.

🚨 9. What Happens If You Skip Gas Pressure Setup

Skipping pressure setup is the #1 cause of:

❌ Delayed ignition

❌ Burner noise

❌ Flame rollout

❌ Cracked heat exchangers

❌ Overfiring

❌ Underfiring

❌ High CO

❌ Flickering flame

❌ Pressure switch problems

❌ Poor efficiency

❌ Shortened furnace lifespan

Goodman furnaces are incredibly dependable —

but only when gas input is perfect.

🧠 10. Jake’s 5-Minute Gas Pressure Setup Summary (Print This)

✔ Check static inlet pressure

✔ Check dynamic inlet pressure

✔ Measure manifold pressure

✔ Adjust regulator to spec

✔ Verify flame behavior

✔ Test temperature rise

✔ Test static pressure

✔ Look for burner abnormalities

✔ Document final readings

This takes 5 minutes.

It prevents years of problems.

🏁 Conclusion: Perfect Flame, Zero Callbacks

Every furnace has a personality.

The Goodman GR9S960803BN?

She likes:

-

precise gas pressure,

-

clean combustion air,

-

stable draft,

-

clean burners,

-

balanced airflow.

Set them correctly, and the flame becomes a work of art —

tight, blue, clean, and efficient.

Jake’s 5-Minute Gas Pressure Setup guarantees:

-

no soot

-

no rollouts

-

no noisy burners

-

no callbacks

-

no premature heat exchanger failures

Gas tuning isn’t complicated.

It’s a discipline.

Learn the steps.

Follow them every time.

And your installs will fire like a natural gas symphony —

on the first try.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: The Coil Alignment Trick: How Jake Pairs an Evaporator Coil With a Furnace Without Choking Airflow