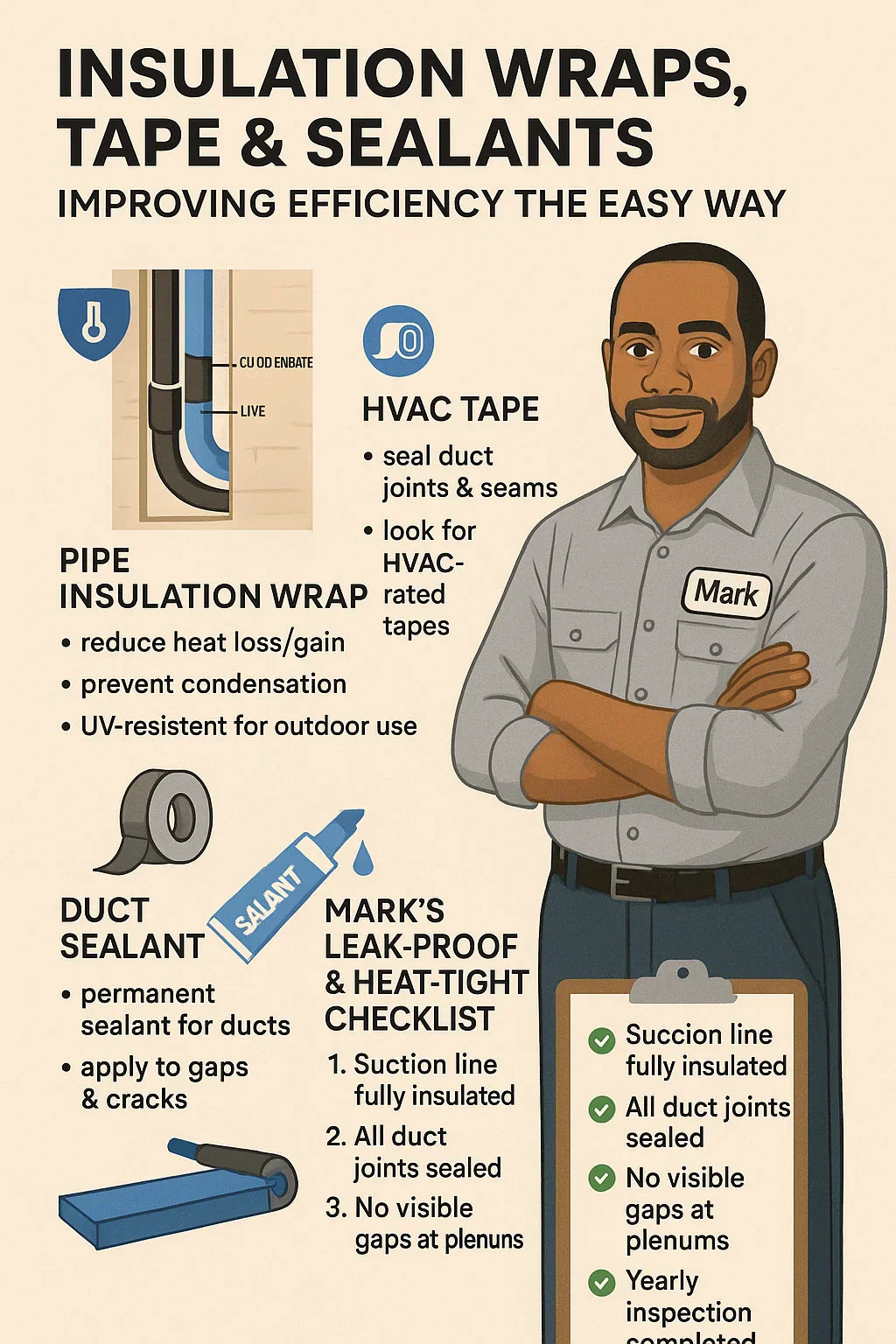

🛠 Insulation Wraps, Tape & Sealants: Improving Efficiency the Easy Way

By Mark — Your HVAC Guy Who Loves the Small Details

When people think about improving their HVAC efficiency, they often picture new equipment, high-tech thermostats, or fancy air purifiers. But sometimes, the biggest bang for your buck comes from the small stuff—like insulation wraps, HVAC tape, and sealants.

I’ve seen homeowners spend thousands on a new system while leaving uninsulated refrigerant lines baking in the sun, or duct joints leaking cool air into an attic. It’s like buying a Ferrari and leaving the trunk wide open while driving.

This guide will show you how these low-cost accessories can make your system run better, last longer, and save you money.

🧵 1. What Are Insulation Wraps, Tape & Sealants?

Insulation Wraps — Flexible foam or rubber material that wraps around refrigerant lines, condensate pipes, or ductwork to prevent heat transfer and condensation.

HVAC Tape — Heavy-duty tape designed to seal duct seams and joints. Unlike standard “duct tape” from the hardware aisle, HVAC tape is often aluminum foil-based or specialized for temperature and moisture resistance.

Sealants — Mastic or caulk-like materials used to permanently seal leaks in ducts, plenums, or around penetrations.

🌡 2. Why They Matter for Efficiency

-

Reduce heat loss/gain — Keep refrigerant at the right temperature from coil to condenser.

-

Prevent condensation — Avoid moisture buildup that can lead to mold or water damage.

-

Stop air leaks — Keep conditioned air in the ducts, not leaking into attics or crawlspaces.

-

Extend equipment life — Reduce strain on compressors and blowers.

Mark’s Note: Every BTU lost through leaks or uninsulated lines is money you’ve already paid for—literally going into thin air.

📏 3. Insulation Wraps — Types & Uses

Common types:

-

Rubber insulation (EPDM) — Flexible, UV-resistant, great for outdoor refrigerant lines.

-

Polyethylene foam — Lightweight, affordable, less durable in direct sun.

-

Fiberglass wrap — High-temperature tolerance, common for ducts.

Where to use:

-

Suction line (the larger copper tube) — MUST be insulated to maintain refrigerant temperature.

-

Condensate drain lines — Prevent sweating in humid spaces.

-

Ductwork in unconditioned areas — Basements, attics, crawlspaces.

🪤 4. HVAC Tape — Choosing the Right Kind

Forget the “duck” tape stereotype. True HVAC tapes include:

-

Foil tape — Aluminum-backed, high-temperature rated, UL 181 approved for ducts.

-

Butyl tape — Flexible sealant tape, great for irregular surfaces and long-term moisture sealing.

-

Cloth-reinforced foil — Stronger tear resistance for high-vibration areas.

Mark’s Tip: Look for UL 181A or UL 181B labeling—this means it’s tested for HVAC use.

🏗 5. Sealants — Mastic vs. Caulk

-

Mastic — Thick, paste-like, brushed on with a paintbrush or applied with a trowel. Flexible when dry, long-lasting.

-

HVAC-grade caulk — Silicone or acrylic latex with additives for heat/moisture resistance. Easier to apply neatly but may not last as long in vibration-heavy spots.

Where to use:

-

Plenum seams

-

Duct joint connections

-

Wall/ceiling penetrations around ductwork

🛠 6. How to Install for Best Results

Insulation Wraps:

-

Cut to length with a utility knife.

-

Wrap snugly around the pipe or duct—no gaps.

-

Secure seams with UV-resistant tape outdoors.

HVAC Tape:

-

Clean surface—dust, oil, and moisture prevent adhesion.

-

Apply tape smoothly—avoid wrinkles or bubbles.

-

Press firmly along the full length for a solid bond.

Sealants:

-

Clean and dry the area.

-

Apply mastic or caulk generously to fill gaps.

-

Let cure per manufacturer instructions before running system.

🧽 7. Maintenance & Lifespan

-

Insulation Wraps: Inspect yearly—replace if cracked, brittle, or missing sections.

-

HVAC Tape: Check for peeling edges or loss of adhesion; replace as needed.

-

Sealants: Look for cracks or gaps and reapply every 5–10 years, or sooner if damaged.

🚨 8. Common Mistakes to Avoid

-

Using standard duct tape — It dries out, peels, and fails within months in HVAC conditions.

-

Leaving suction line insulation exposed to direct sun without UV protection.

-

Applying sealant on dirty, wet, or oily surfaces—won’t bond well.

-

Wrapping insulation too loosely, leaving air gaps.

📊 9. The Efficiency Payoff

Case Example:

A homeowner had refrigerant lines running through a 120°F attic with old, crumbling insulation. After replacing with new 3/4" wall rubber insulation and sealing attic ducts with foil tape and mastic, their cooling bills dropped by 12% the next month.

📌 10. Mark’s Leak-Proof & Heat-Tight Checklist

-

✅ Suction line fully insulated with UV-protected wrap

-

✅ All duct joints sealed with UL 181-rated tape or mastic

-

✅ No visible gaps at plenums or wall penetrations

-

✅ Condensate line insulated in humid spaces

-

✅ Yearly inspection completed

🏁 11. Key Takeaways

-

Small accessories can have big efficiency benefits.

-

Choose HVAC-rated materials—don’t skimp on quality.

-

Proper installation is key to long-term results.

-

Annual inspection keeps insulation, tape, and sealants doing their job.

References

In the next topic we will read more about: Seasonal Maintenance Kits: What’s Included & How to Use Them