🏁 Introduction: Tony’s DIY Dilemma

I’ve been a hands‑on guy most of my life. Plumbing repairs, flooring installs, even a full bathroom remodel—I’ve tackled them all. But when my old 5‑ton R‑410A system finally gave out, I faced a new question:

“Should I install my new 5‑ton R‑32 heat pump myself, or is this one of those jobs best left to the pros?”

If you’re reading this, chances are you’re weighing the same decision. After weeks of research, phone calls with contractors, and more than a few cups of coffee, I learned that installing a 5‑ton R‑32 heat pump isn’t like replacing a water heater. It’s a whole different ballgame.

Let’s walk through what’s involved, the real risks and rewards, and how to decide whether DIY or professional installation is the right move for you.

🏗️ What Installing a 5‑Ton R‑32 Heat Pump Involves

A lot of people think a heat pump install is just “drop the box, plug it in, and you’re done.” I wish it were that easy. Here’s the truth:

🧰 Major Installation Tasks

-

Site Prep & Pad Setup

-

A 5‑ton condenser is no lightweight—you’ll need a leveled concrete or composite pad to support it.

-

-

Electrical Service Upgrade

-

Most 5‑ton units need a 240V, 50–60 amp circuit.

-

You may need a sub‑panel or breaker upgrade.

-

-

Line Set & Refrigerant Handling

-

R‑32 is an A2L mildly flammable refrigerant—you must use A2L‑rated copper line sets.

-

Lines must be properly sized, insulated, and sealed.

-

-

Indoor Air Handler & Ductwork Connection

-

Installing the air handler, ensuring proper airflow, and sometimes resizing ducts.

-

Poor airflow = wasted efficiency.

-

-

Vacuum & Pressure Testing

-

Before charging refrigerant, lines must be vacuumed and tested for leaks.

-

Special tools: micron gauge, vacuum pump, and nitrogen testing kit.

-

-

Refrigerant Charging & Start‑Up

-

Requires EPA 608 certification to legally handle refrigerants.

-

Incorrect charging = damaged compressor and voided warranty.

-

👉 According to Energy.gov, correct installation is the single most important factor in heat pump performance.

⚠️ Safety & Code Considerations

Here’s where DIY enthusiasm often runs into a brick wall.

🔥 Handling R‑32 Refrigerant

-

Classified as A2L (mildly flammable).

-

Requires careful leak prevention and adequate ventilation.

-

Missteps can lead to fire hazards or toxic exposure.

Only EPA 608‑certified technicians are allowed to handle R‑32 refrigerant

🛑 Permits & Inspections

Most cities require:

-

Electrical permit

-

Mechanical/HVAC permit

-

Final inspection before system operation

If you DIY without permits, you risk:

-

Failed inspections

-

Insurance denial in case of fire or damage

-

Local fines

Tony’s Note:

“I checked with my county inspector—no licensed contractor, no approval. That sealed the deal for me.”

💵 Cost Comparison: DIY vs. Pro

Everyone loves saving money—but the numbers tell a more complicated story.

👷 Professional Installation

-

Labor Costs: $4,500 – $7,000

-

Total Installed System: $14,000 – $18,000 (equipment + labor)

-

Includes:

-

Permits & inspections

-

Certified refrigerant handling

-

System commissioning & testing

-

Full warranty coverage

-

🧰 DIY Attempt

-

Potential Savings: $4,000 – $6,000

-

Hidden Costs & Risks:

-

Tools ($1,000 – $2,500 for pumps, gauges, meters)

-

Risk of damaging $10,000 worth of equipment

-

Voided manufacturer warranty

-

Safety hazards

-

🏠 Who Might Consider DIY?

✔️ Possible Candidates

-

Licensed HVAC Technicians installing their own unit.

-

Highly experienced DIYers working under the supervision of a certified installer.

-

Homeowners who want to do site prep, duct sealing, and electrical rough‑in (with proper permits) before calling in the pro for refrigerant and final testing.

❌ Not Recommended For

-

First‑time installers.

-

Anyone without EPA 608 certification.

-

Homes requiring significant ductwork redesign.

-

Folks relying on the manufacturer’s full 10–12 year warranty.

Tony’s Tip:

“If you’ve never pulled a vacuum on a line set or calculated airflow in CFM, this probably isn’t your project.”

🛠️ Hybrid Approach: DIY Prep + Pro Finish

One option I strongly recommend is a hybrid approach. You handle the parts you can safely do, then call in the pro for the finish.

🏗️ Homeowner Tasks

-

Pour or level the condenser pad

-

Seal and clean existing ductwork

-

Install smart thermostat wiring

-

Hire an electrician for panel upgrades

👨🔧 Pro Technician Tasks

-

Line set installation

-

Refrigerant vacuum & charging

-

Leak testing and compliance checks

-

System commissioning for warranty registration

This approach can save $1,000 – $2,000 without compromising safety or voiding warranties.

🌎 Warranty & Longevity Considerations

📜 Manufacturer Warranties

Most leading brands (Daikin, Goodman, Carrier) require licensed installation to activate warranty coverage.

-

Without professional install: Warranty may be void.

-

With licensed install: 10–12 years coverage on compressor and parts.

⏳ Long‑Term Value

-

Professional installs are tested and optimized for efficiency.

-

A poor DIY install can shorten lifespan by 5–7 years due to improper charging or airflow.

👉 EnergyStar guidelines stress professional installation for warranty and performance compliance.

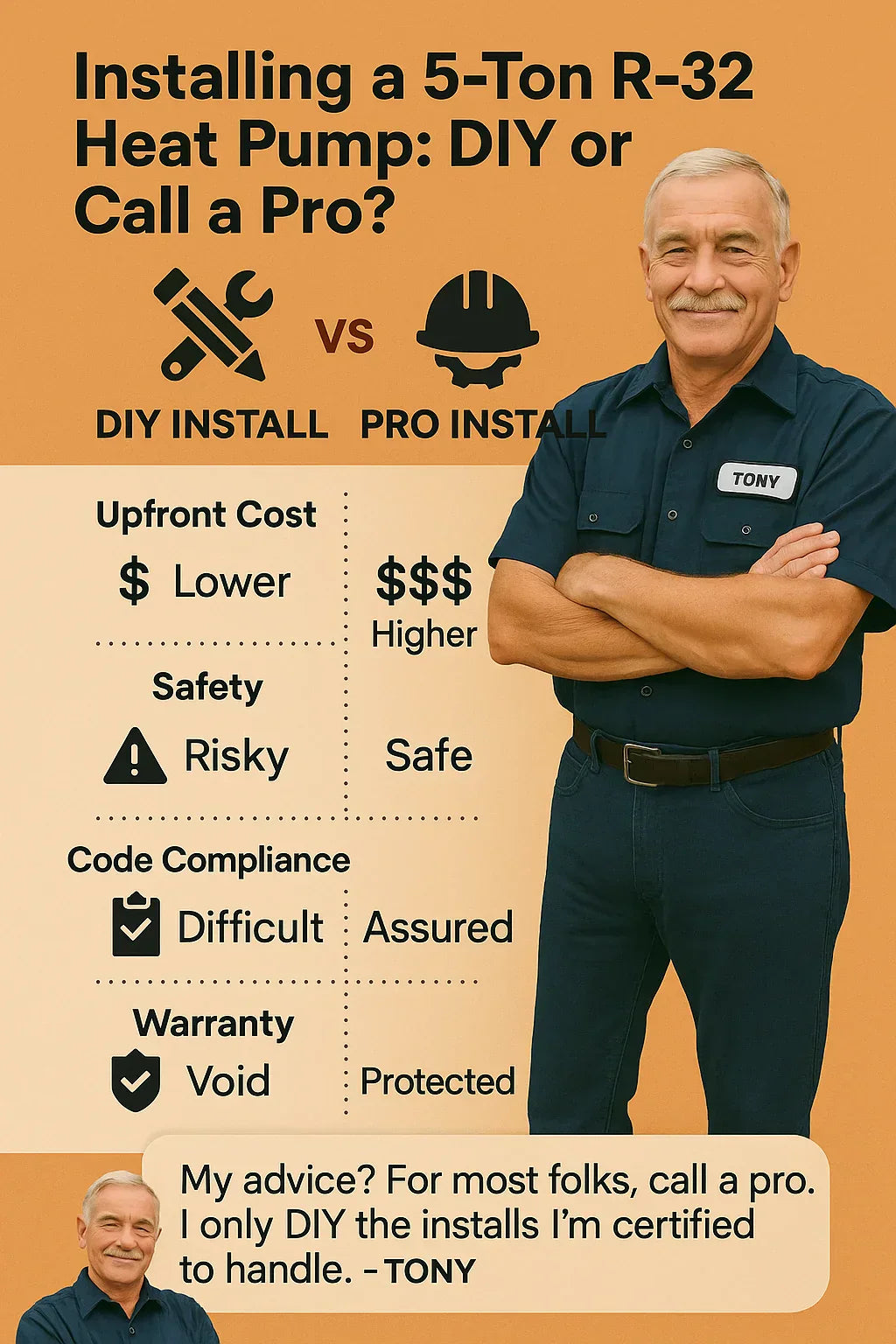

📊 Tony’s Pros & Cons Breakdown

| Factor | DIY Install | Pro Install |

|---|---|---|

| Upfront Cost | Lower (save $4k–$6k) | Higher ($14k–$18k total) |

| Safety | Risky (A2L refrigerant, high voltage) | Safe & compliant |

| Code Compliance | Difficult without license | Assured |

| Warranty Coverage | Usually void | Fully protected |

| Long‑Term Value | Low–Moderate | High |

| Best For | Licensed HVAC pros | Most homeowners |

📌 Real‑World Scenarios

🏡 Scenario 1: Licensed Tech DIY

-

Cost: $10,000 equipment + $1,500 tools

-

Result: Full compliance (because of license), warranty intact.

🏠 Scenario 2: Experienced DIYer, No License

-

Cost: $10,000 equipment + $2,000 tools

-

Risks: Failed inspection, no warranty, unsafe refrigerant handling.

-

Savings lost if rework is needed.

🏘️ Scenario 3: Hybrid Approach

-

Homeowner does pad, duct sealing, thermostat wiring.

-

Pro handles refrigerant, testing, final connections.

-

Cost: $12,500 – $13,500

-

Warranty preserved, safe, and still some savings.

🏁 Conclusion: Tony’s Recommendation

At the end of the day, here’s my bottom line:

“I love rolling up my sleeves, but when it came to my 5‑ton R‑32 heat pump, I called in the pros for the heavy lifting. I still prepped the site and sealed my ducts—that saved me some cash—but the refrigerant charging and final startup? That’s not a job I’d risk.”

My advice:

-

If you’re a licensed HVAC pro, go for it.

-

If not, consider a hybrid approach—but let a certified installer handle refrigerant and commissioning.

-

For most homeowners, a full professional install is the safest and smartest choice.

✅ Tony’s Homeowner Checklist

-

Check local permit requirements before starting.

-

Confirm your electrical panel can handle a 5‑ton system.

-

Decide if you’ll DIY prep (pad, duct sealing, thermostat wiring).

-

Hire a licensed HVAC pro for refrigerant handling.

-

Register your warranty immediately after installation.

-

Keep copies of permits and inspection approvals

In the next topic we will know more about: Clearance, Noise & Design Considerations for a 5-Ton R-32 System