Homeowners often tell me, “The installer was only here an hour — what could they really have done?”

A lot, actually.

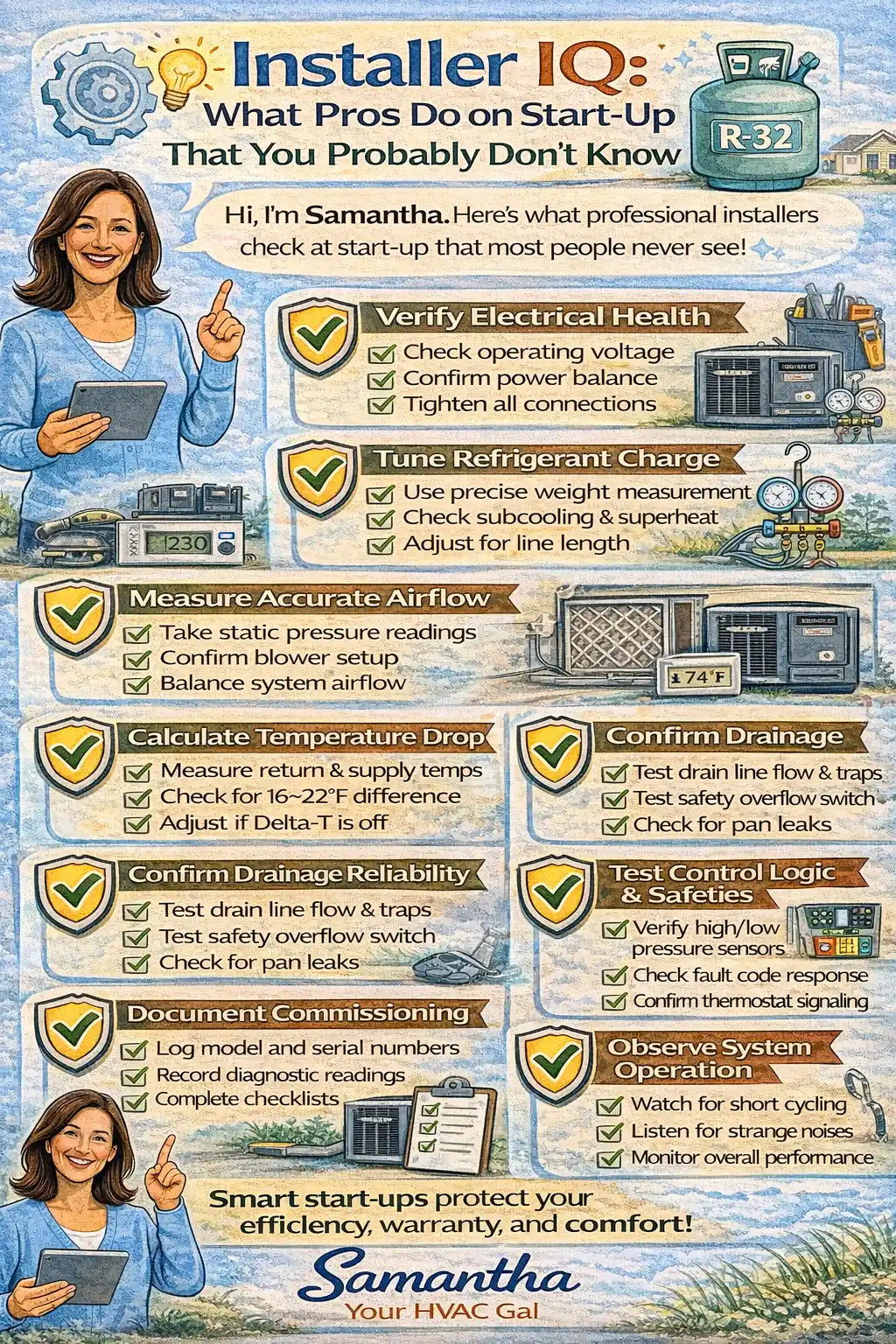

I’m Samantha, and today I want to pull back the curtain on professional HVAC start-up procedures — the checks, measurements, and adjustments technicians make that most homeowners never see.

Because here’s the truth:

👉 A system can turn on and cool your home… and still not be properly started.

This guide explains what experienced installers check, why it matters, and how it protects your comfort, efficiency, and warranty.

🔍 Why Professional Start-Up Is More Than “Turning It On”

A professional start-up (often called commissioning) is not about proving the system works.

It’s about confirming that:

-

The system operates within design specifications

-

Components are protected from early failure

-

Efficiency targets (like SEER2) are achievable

-

Warranty conditions are met

🔗 ACCA system commissioning standards:

https://www.acca.org/standards

⚡ Step 1: Electrical Verification You Can’t Do by Sight

Before refrigerant even enters the conversation, pros focus on electricity.

What Installers Actually Check

✔ Line voltage under load

✔ Voltage balance across phases

✔ Proper grounding

✔ Correct breaker sizing

✔ Tightness of all electrical connections

Why it matters:

-

Low voltage quietly damages compressors

-

Poor grounding risks control boards

-

Loose connections cause heat buildup

🔗 NFPA electrical safety overview:

https://www.nfpa.org/education-and-research/home-fire-safety/electrical-safety-in-the-home

💡 Samantha’s Insight:

Electrical issues often don’t fail fast — they fail expensively months later.

❄️ Step 2: Refrigerant Charging Is Precision Work

Homeowners often think refrigerant is adjusted “until it feels cold.”

Professionals know better.

What Pros Actually Do

✔ Charge refrigerant by weight

✔ Verify subcooling and superheat

✔ Compare readings to manufacturer charts

✔ Adjust for line-set length and ambient temperature

This is especially critical for R-32 systems, which are less forgiving of errors.

🔗 EPA refrigerant handling requirements:

https://www.epa.gov/section608

💡 Samantha’s Insight:

A system can cool today and still be dangerously mischarged.

🌬️ Step 3: Airflow Measurement — Not Guesswork

Airflow is the most overlooked efficiency factor.

What Installers Measure

✔ Static pressure across the system

✔ Blower speed settings

✔ Return and supply balance

✔ Duct restrictions

Why this matters:

-

Too little airflow = coil icing

-

Too much airflow = poor dehumidification

-

Incorrect airflow = lost SEER2 efficiency

🔗 ASHRAE airflow fundamentals:

https://www.ashrae.org/technical-resources

🌡️ Step 4: Temperature Differential (Delta-T) Testing

Pros don’t just feel the air — they measure it.

Typical Target

✔ 16–22°F temperature drop between return and supply

If Delta-T is off, installers investigate:

-

Refrigerant charge

-

Airflow issues

-

Coil cleanliness

-

Duct leakage

🔗 ENERGY STAR on AC performance:

https://www.energystar.gov/saveathome/heating-cooling

💧 Step 5: Condensate & Drain Protection Checks

Water damage is one of the most common post-install problems.

What Pros Confirm

✔ Drain slope and trap configuration

✔ Drain flow during operation

✔ Float switch operation

✔ Pan integrity

🔗 EPA moisture and mold prevention:

https://www.epa.gov/mold/mold-course-chapter-2

💡 Samantha’s Insight:

Many installers catch water issues before they ever reach the homeowner.

🔄 Step 6: Control Board & Safety Logic Testing

Modern systems protect themselves — if configured correctly.

What Pros Test

✔ Compressor delay timers

✔ High- and low-pressure switches

✔ Thermostat communication

✔ Fault code response

Skipping this step can cause:

-

Nuisance shutdowns

-

False error codes

-

Hard starts after power loss

📋 Step 7: Documentation & Warranty Protection

This part never happens in front of the homeowner — but it matters.

What Installers Document

✔ Model and serial numbers

✔ Electrical readings

✔ Refrigerant charge values

✔ Airflow settings

✔ Commissioning checklist

Why it matters:

-

Required for warranty claims

-

Protects you if issues arise later

-

Confirms system met specs at start-up

🔗 AHRI system standards overview:

https://www.ahrinet.org/standards

🧪 Step 8: Final Observation Under Real Conditions

Before leaving, good installers:

-

Let the system run

-

Watch cycle behavior

-

Listen for abnormal sounds

-

Verify thermostat response

This ensures:

✔ No short cycling

✔ No delayed failures

✔ No overlooked issues

🚫 What Happens When These Steps Are Skipped

Systems that skip professional start-up often suffer from:

❌ Higher energy bills

❌ Frequent service calls

❌ Shortened compressor life

❌ Warranty claim denials

❌ Comfort complaints

The system may “work” — just not well or for long.

📋 Samantha’s “Did My Installer Really Commission This?” Checklist

Ask yourself:

✔ Were airflow and refrigerant measured — not guessed?

✔ Were electrical readings taken?

✔ Did the system run long enough to observe behavior?

✔ Was documentation provided?

If you’re unsure, a post-install commissioning visit can still be done.

✅ Final Thoughts from Samantha

Professional installers don’t just install equipment — they protect investments.

What they do at start-up:

-

Prevents early failures

-

Preserves efficiency

-

Protects warranties

-

Delivers comfort you can trust

If you ever wonder what separates a smooth HVAC experience from a frustrating one — start-up quality is usually the answer.

And now, you know what to look for.