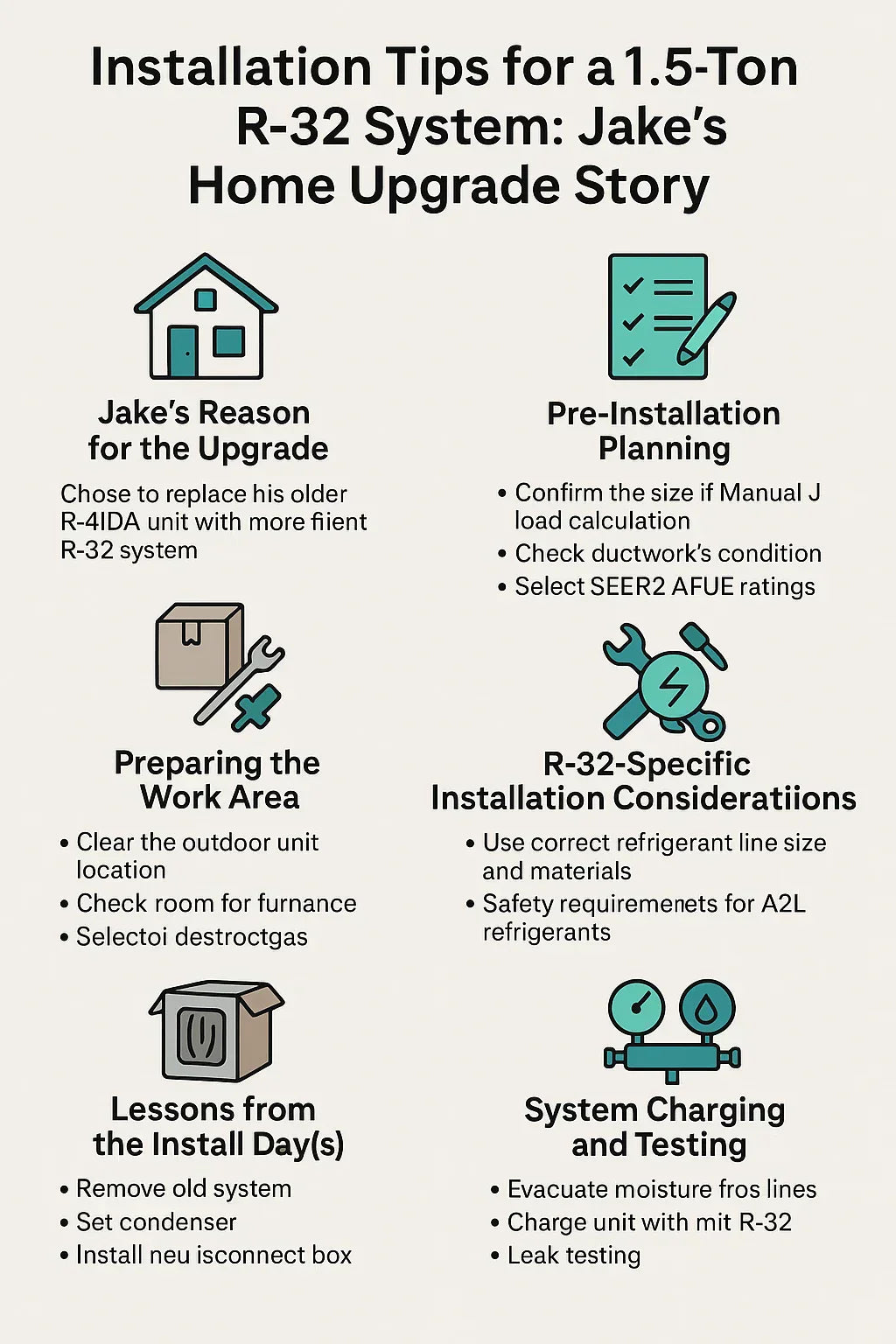

🏠 Why I Finally Upgraded to a 1.5-Ton R-32 System

I’d been nursing my old R-410A AC and gas furnace combo for years — patching refrigerant leaks, replacing capacitors, and hoping each spring that it would last just “one more summer.”

By 2024, the writing was on the wall:

-

My electric bills were climbing even though I wasn’t changing my thermostat settings.

-

The system was short-cycling in mild weather and running non-stop in peak heat.

-

My tech warned that R-410A was getting expensive and harder to source.

I’d already read up on R-32 refrigerant and knew it was more efficient and environmentally friendly than R-410A.

When a tax rebate program popped up for high-efficiency systems in my area, I decided it was time to pull the trigger.

Best 1.5 Ton AC and Gas Furnaces

📋 Pre-Installation Planning

Before anyone touched a wrench, I did some homework.

This prep phase is critical — and can save you thousands in the long run.

🧮 Step 1: Manual J Load Calculation

Even though my home is about 900 sq ft, I didn’t want to assume a 1.5-ton system was perfect without proof.

My HVAC contractor ran a Manual J load calculation (ACCA Manual J Overview) factoring in:

-

Wall and attic insulation

-

Window type and direction

-

Ceiling height

-

Local climate zone

-

Occupancy and appliances

Result? 1.46 tons of cooling needed. That confirmed a 1.5-ton R-32 AC was spot-on.

📏 Step 2: Ductwork Assessment

My ductwork was original to the house — 20+ years old. We found:

-

A few air leaks at joints and boots

-

Slight undersizing in one branch run

We sealed leaks and upsized one duct to avoid airflow restrictions.

If you skip this step, even the best R-32 system can’t perform at its peak.

🎯 Step 3: Choosing Efficiency Ratings

I went with:

-

15.2 SEER2 R-32 condenser

-

96% AFUE two-stage gas furnace

The sweet spot for my budget and climate — higher efficiency than my old unit, but not the extreme cost of 18+ SEER2 or modulating furnaces.

📎 Understanding SEER2 and AFUE

🛠 Step 4: Selecting an Installer

I chose a licensed, insured HVAC contractor with:

-

A2L refrigerant handling certification

-

R-32-compatible tools

-

Positive reviews mentioning neat, code-compliant work

🧰 Preparing the Work Area

🏡 Outside: Condenser Location

We cleared:

-

Overgrown shrubs within 3 feet of the pad

-

Debris from the coil exhaust path

-

A path for installers to move equipment in and out

🏚 Inside: Furnace & Coil Area

-

Cleared space around the furnace in the utility room

-

Removed stored boxes and shelving that blocked access

-

Ensured 120V outlet for service tools was working

⚡ Utility Prep

-

Verified electrical panel capacity

-

Shut-off valves for gas and water tested

-

Space for a new disconnect box outside

🔧 R-32-Specific Installation Considerations

R-32 is an A2L mildly flammable refrigerant, so it comes with special requirements.

🧵 Refrigerant Line Materials & Sizing

-

Copper tubing rated for A2L refrigerants

-

Line length matched to manufacturer specs to ensure proper charge

🛡 Safety Measures

-

Leak detectors rated for R-32

-

Adequate ventilation in work areas

-

Technicians wore PPE and followed R-32 safety guidelines (ASHRAE A2L Safety Sheet)

🔩 Component Compatibility

The indoor coil and expansion valve must be R-32-specific — R-410A parts won’t work properly.

💡 Lessons from the Install Day(s)

My install took two full days.

📆 Day 1: Removal and Prep

-

Recovered R-410A refrigerant per EPA guidelines (EPA Refrigerant Handling Rules)

-

Removed old condenser and furnace

-

Disposed of equipment through certified recycling

-

Installed new furnace, leveled and secured it

-

Modified duct connections for better fit and airflow

📆 Day 2: Coil, Condenser & Connections

-

Mounted and leveled new R-32 condenser

-

Ran new refrigerant lines with proper insulation

-

Installed R-32 indoor coil and sealed plenum

-

Connected electrical wiring to code

-

Pressure-tested and evacuated lines

Jake’s note: The tech showed me how they purged nitrogen while brazing to prevent scale inside copper lines — something many homeowners don’t realize matters.

⚡ Electrical & Gas Connections

-

Electrical: Matched breaker size to manufacturer specs; installed new outdoor disconnect

-

Gas: Checked line size and pressure; tested for leaks with electronic sniffer

🌀 System Charging and Testing

1. Evacuation

Pulled a deep vacuum to remove air/moisture — crucial for R-32 efficiency.

2. Weigh-In Charge

Charged the system by weight using manufacturer’s chart for my line length.

3. Leak Test

Electronic leak detector pass + soap bubble check.

📎 HVAC School — Charging A2L Refrigerants

📜 Permits and Inspections

My city required:

-

Mechanical permit

-

Gas permit

-

Final inspection for both

We passed on the first try — largely because my installer followed code to the letter.

✅ Jake’s Post-Install Checklist

-

Smart Thermostat Setup — Integrated with my Wi-Fi and programmed schedules

-

Warranty Registration — Both furnace and condenser registered within 60 days

-

First Maintenance Appointment — Booked for 6 months after install to recheck charge and airflow

🛠 Pro Tips I Learned Firsthand

-

Don’t skimp on duct sealing — my airflow gain was noticeable.

-

Ask your installer to label refrigerant type clearly on the unit.

-

Be home during install so you can see and ask questions — I learned a ton.

-

If you’re adding accessories (humidifier, purifier), install them now, not later.

-

Keep your permit documents and inspection reports — they help with resale.

📊 Time & Cost Recap

-

Prep & planning: 1 week

-

Install: 2 days

-

Total cost: $9,200 before rebates, $8,000 after

-

ROI: Estimated payback in ~5 years from efficiency gains

In the next topic we will know more about: Maintaining Your 1.5-Ton R-32 AC and Gas Furnace: Filters, Coils & Seasonal Care