🏠 Introduction: Tony’s Advice Before You Buy

“Hey folks, Tony here. Horizontal AC units are a great option for homes with attics, crawlspaces, or basements where a vertical system just won’t fit. But before you go online and hit ‘Add to Cart’, you need to understand what goes into installing one.

Goodman GPCH34831 Horizontal Air Conditioner 4 Ton, 208/230V, R-32 Refrigerant

Horizontal systems aren’t just plug-and-play. They need the right space, ductwork, electrical supply, drainage, and permits to work safely and efficiently.

In this guide, I’ll walk you through everything you should know before buying — so you don’t end up with an expensive headache later.”

📏 Space & Clearance Requirements

One of the first questions I ask homeowners is: “Where’s it going to sit?”

Dimensions

-

Horizontal AC units are longer and lower than vertical units.

-

A Goodman 4 Ton R-32 horizontal system, for example, measures about 50–60 inches long, 20–25 inches high, and 30 inches wide.

Clearance Rules

-

Leave at least 24 inches of clearance on the service side.

-

Maintain 12–18 inches around ducts for airflow.

-

Ensure 36 inches overhead clearance in attics or crawlspaces for service access.

Tony’s tip: Grab a tape measure before buying. If your attic hatch is too small, you may need modifications just to get the unit in.

📖 Source: Energy.gov – HVAC Installation Considerations

🌬️ Ductwork Considerations

Your ducts are the highway for conditioned air — and if they’re undersized or leaky, even the best AC won’t work properly.

Common Modifications

-

Horizontal units often require new plenums (supply/return transitions).

-

Duct resizing may be needed if airflow is restricted.

-

Insulation upgrades reduce energy waste in hot attics.

Duct Sealing

-

Up to 30% of conditioned air can be lost through leaks.

-

Sealing with mastic or tape is critical for efficiency.

Tony’s tip: If your ducts are older than 15 years, have them inspected before installing a new unit.

📖 Source: ENERGY STAR – Duct Sealing & Insulation

🔌 Electrical Setup

Horizontal ACs need dedicated electrical service.

Requirements

-

Voltage: 208/230V, single phase

-

Breaker: 30–50 amps depending on tonnage

-

Disconnect box required within 6 feet

Common Issues

-

Older homes often lack the correct breaker size.

-

Panels may need upgrades to handle the load.

-

Improper wiring can cause tripped breakers or fire hazards.

Tony’s tip: Don’t assume your electrical panel is ready. Have an electrician confirm before the HVAC crew arrives.

📖 Source: Electrical Safety Foundation International – HVAC Electrical Safety

💧 Drainage & Condensate Control

Horizontal units generate gallons of water on humid days. If that water doesn’t drain properly, you risk ceilings stains, mold, and costly repairs.

Drainage Setup

-

Primary drain line slopes to the outside or a plumbing drain.

-

Secondary pan & line catch overflow if the primary clogs.

-

Float switch shuts off system if water backs up.

Tony’s tip: Always invest in a secondary drain pan and float switch. I’ve seen $200 accessories save homeowners thousands in ceiling repairs.

📖 Source: HVAC.com – AC Drain Line Guide

📑 Permits, Codes & Inspections

Don’t skip this part — it can cost you down the road.

Why Permits Matter

-

Local building departments require permits for HVAC installs.

-

Inspections ensure safety, proper refrigerant handling, and code compliance.

-

Skipping a permit can void your warranty and insurance coverage.

Costs

-

Permits typically cost $150–$500 depending on your city.

Tony’s tip: If a contractor tells you “we don’t need a permit,” that’s a red flag.

📖 Source: International Code Council – Mechanical Code Overview

👷 DIY vs. Professional Work

I know a lot of you DIY folks out there want to save money. But with AC installs, you need to know your limits.

What You Can Do Yourself

-

Prep the space (clear access, measure clearance).

-

Seal and insulate ducts.

-

Install platforms or pads.

What Requires a Licensed Pro

-

Refrigerant handling (EPA Section 608 certification required).

-

Electrical wiring and breaker work.

-

Charging, leak testing, and system startup.

Tony’s tip: Do what you can to prep, but let pros handle the technical work. The risks of DIY mistakes — leaks, shocks, code violations — just aren’t worth it.

📖 Source: EPA – Refrigerant Management Rules

💰 Cost & Time Expectations

So, how much and how long?

Time

-

Standard horizontal install: 1–2 days

-

Complex installs (duct/electrical work): 3–4 days

Costs

-

Equipment: $3,200–$4,500

-

Labor: $1,200–$3,000

-

Extras (duct, electrical, drainage, permits): $1,000–$3,000

-

Total typical budget: $7,500–$9,000

📖 Source: Central AC Cost Guide

Tony’s tip: Always budget a 10% cushion for surprises. Something always comes up.

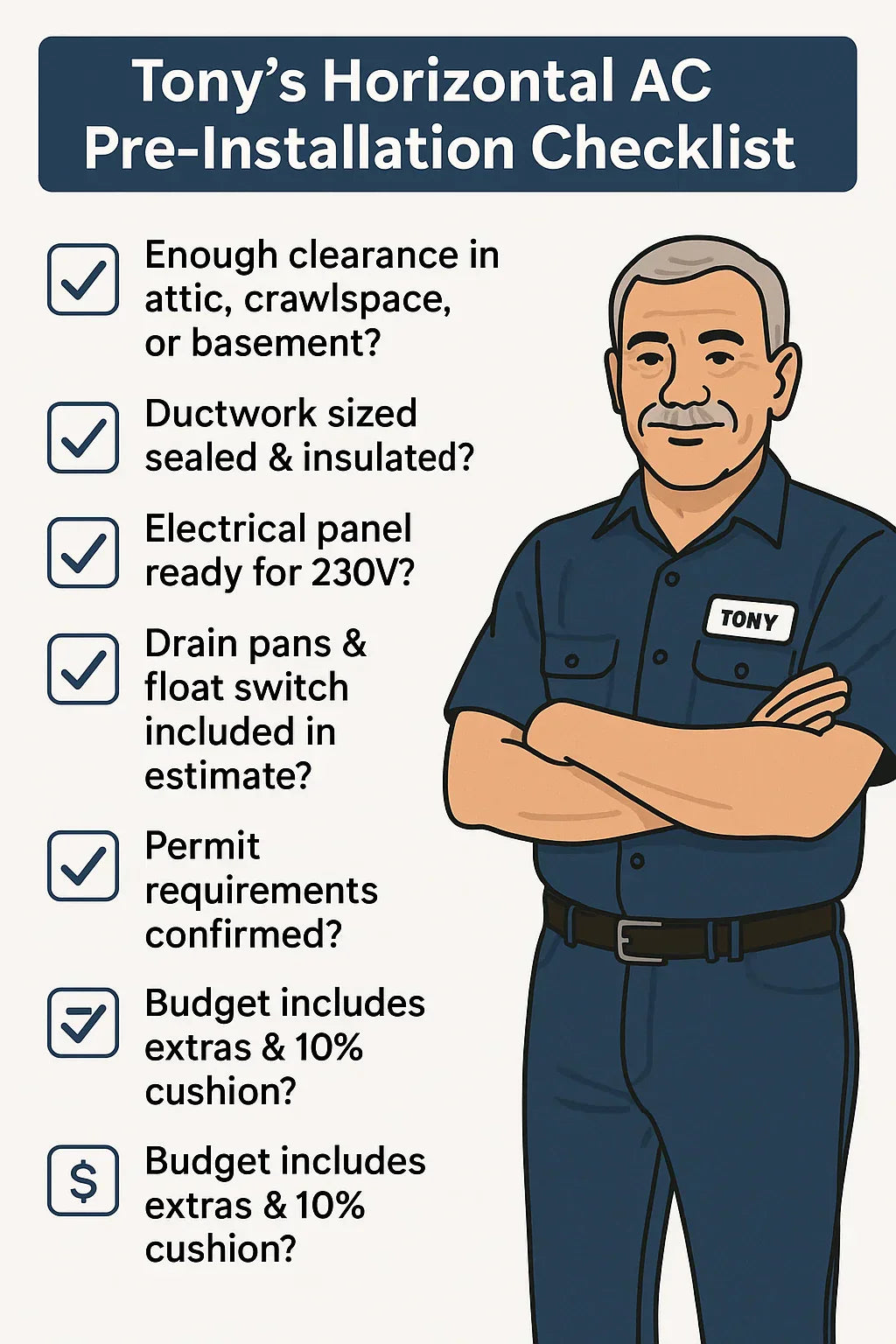

✅ Tony’s Pre-Buy Checklist

Here’s the quick version — print this out before you buy:

-

✅ Enough clearance in attic, crawlspace, or basement?

-

✅ Ductwork sized, sealed, and insulated?

-

✅ Electrical panel and breaker ready for 230V?

-

✅ Drain pans and float switch included in estimate?

-

✅ Permit requirements confirmed?

-

✅ Budget includes extras + 10% cushion?

🏁 Conclusion: Tony’s Bottom Line

Horizontal ACs are a great solution for tight spaces, but they come with their own set of challenges.

Plan ahead for space, ductwork, electrical, drainage, and permits, and you’ll save yourself time, money, and frustration.

Tony’s final word: “Don’t just buy a horizontal AC because it looks like it’ll fit. Make sure your home is ready, or you’ll be sweating more over the bill than the heat.”

In the next topic we will know more about: Performance in Extreme Heat: Can a 4 Ton AC Handle Hot Summers?