🔧 1. Introduction — Why Installation Quality Matters More Than Ever

When I (Jake) first decided to upgrade my old R-410A system to an new R-32 condenser, I figured the hard part would be picking the brand and tonnage. But once the equipment arrived, I quickly realized: installation is what makes or breaks your system’s efficiency, safety, and lifespan.

A poorly installed condenser can waste energy, leak refrigerant, or even void your warranty before you’ve had a single cool night. The truth is, even the most advanced refrigerant like R-32 only performs as designed when it’s properly installed — sealed, charged, and tested to spec.

In this guide, I’ll walk you through everything a homeowner should know before and during installation — not so you can DIY it entirely (R-32 is a refrigerant that requires certified handling), but so you can understand what a professional should be doing at each step. You’ll come away with a checklist, a clearer sense of safety, and the confidence to ensure your new R-32 condenser runs efficiently for years.

🧰 2. What Exactly Is Inside an R-32 Condenser?

Before we talk installation, it helps to understand what’s actually in that outdoor box humming beside your home.

An R-32 condenser unit contains:

-

Compressor: The heart of your system, pumping refrigerant through the coils.

-

Condenser coils: Where hot refrigerant gas releases heat to the outdoor air.

-

Fan and motor: Draws air across coils for cooling.

-

Electrical control board: Coordinates compressor, fan, and signals from the thermostat.

-

Service valves and refrigerant ports: Connection points for line sets to your indoor coil.

R-32 vs. R-410A — What’s Different for Installers

The biggest change is the refrigerant itself.

R-32 is a single-component refrigerant with a much lower Global Warming Potential (GWP) of about 675 — nearly 70% less than R-410A (≈ 2,088) .

It’s also more efficient at transferring heat, which allows manufacturers to use smaller refrigerant charges and compact coil designs.

But there’s one key difference: R-32 is classified as A2L (mildly flammable) under ASHRAE standards. That means installation practices must minimize leak and ignition risks — proper ventilation, secure fittings, no smoking or open flame during brazing.

📘 Learn more: Daikin – The Future of Refrigerants (R-32 Overview)

As a homeowner, you don’t need to fear R-32 — just respect it. When installed to code, it’s incredibly safe, energy-efficient, and eco-friendly.

📋 3. Pre-Installation Planning: Site, Space & Power Requirements

Before your HVAC tech even lifts the condenser off the truck, you should walk your property and plan where and how it will be installed.

🏡 Choose the Right Location

-

Ventilation: The unit needs plenty of open space for airflow — at least 12–18 inches of clearance on all sides and 5 ft above.

-

Shade: A partially shaded spot improves performance; avoid direct afternoon sun if possible.

-

Drainage: The surface should be level but allow water to drain away after rain.

-

Noise & proximity: Keep at least 3 ft from bedrooms or windows to minimize vibration noise indoors.

-

Avoid obstructions: Don’t place under decks, next to vents, or near dryer exhausts.

Jake’s Tip: I placed mine on the north side of the house — shaded most of the day and protected from lawnmower debris.

⚙️ Mounting Base & Clearance

The condenser should sit on a level concrete or composite pad, ideally 2–3 inches above grade. For rooftop or balcony installs, vibration pads or anti-vibration mounts are a must.

For multi-unit homes, ensure each condenser has its own clearance bubble for airflow.

Visual concept: A top-down diagram showing clearance zones (12 in side, 24 in front, 60 in above).

⚡ Electrical Requirements

Every R-32 condenser needs a dedicated circuit, typically 240 V with a correctly sized breaker.

-

Confirm wire gauge per amp draw on the nameplate.

-

Install a disconnect box within line-of-sight (per NEC 440.14).

-

Use weather-rated conduit and ensure proper grounding.

If your panel’s nearly full, you might need an electrician to add capacity. It’s not a corner to cut — the compressor demands steady voltage.

📗 Reference: Energy.gov – Central Air Conditioner Installation Tips

🧰 4. Tools & Materials Checklist

Even if you’re not doing the install yourself, knowing what’s needed helps you evaluate whether your contractor is prepared.

Core HVAC Tools

-

Vacuum pump (with micron gauge)

-

Manifold gauges rated for R-32

-

Torque wrench (for flare fittings)

-

Nitrogen tank + regulator (for pressure testing)

-

Digital scale (for precise refrigerant charge)

Electrical & Mounting

-

Multimeter & clamp meter

-

Disconnect switch & weatherproof box

-

Rubber vibration pads

-

Level & anchors

-

Conduit, wire, and grounding kit

Safety Gear

-

Fire-rated gloves & goggles

-

R-32 rated leak detector

-

Portable Class B fire extinguisher (for A2L refrigerants)

Jake’s Note: “When the tech rolled up, I checked that he had a nitrogen tank — if he didn’t, I’d have known something was off.”

📘 Reference: ASHRAE – Low-GWP Refrigerant Installation Best Practices

🔒 5. Safety First: Understanding R-32’s A2L Classification

Safety isn’t about fear; it’s about preparation.

A2L – “Mildly Flammable” Explained

-

A = low toxicity, 2L = lower flammability & slow flame propagation.

-

Compared to natural gas or propane, R-32’s ignition energy is much higher and its burn velocity slower.

-

The system design — sealed piping and outdoor placement — means the refrigerant is never exposed during normal operation.

Key Safety Rules for Installation

-

No open flames, smoking, or sparks during brazing.

-

Ensure ventilation during line-set work.

-

Leak testing and vacuuming must be done before charging.

-

Label system as “R-32 refrigerant – A2L” for future servicing.

-

Use only manufacturer-approved tubing and fittings.

📗 Source: TSC Air – Safety Guidelines for R-32 Refrigerant

Jake’s Take: “Safety doesn’t add cost; it adds confidence. My installer taped an R-32 warning label near the disconnect — simple but smart.”

⚙️ 6. Step-by-Step Installation Walkthrough

Let’s demystify what the actual installation looks like, so you know what to watch for or verify.

🪜 Step 1: Site Preparation

-

Level the mounting pad and confirm drainage slope.

-

Place vibration pads under each condenser foot.

-

Ensure the unit is oriented for correct airflow (fan upward, service valves accessible).

🔩 Step 2: Mount the Condenser

-

Bolt or secure the base to prevent shifting.

-

Check spacing between refrigerant valves and wall (so service tools fit).

🔗 Step 3: Install Line Sets

-

Measure correct length; too long causes pressure drop, too short strains fittings.

-

Insulate suction line thoroughly to prevent condensation.

-

Flares must be clean, aligned, and torqued to manufacturer spec — over-tightening causes micro-leaks.

💨 Step 4: Pressure Test

-

Pressurize with dry nitrogen to ~300 psi.

-

Check for leaks with soap solution or electronic detector.

-

Hold pressure for at least 10–15 minutes (no drop allowed).

🕳️ Step 5: Evacuation

-

Connect vacuum pump and pull down to ≤ 500 microns.

-

Hold vacuum for 10 minutes to ensure no leaks or moisture.

⚡ Step 6: Electrical Connections

-

Run power from disconnect to condenser per wiring diagram.

-

Verify proper grounding, polarity, and wire tightness.

-

If your system uses variable-speed communication, connect signal wire as directed.

❄️ Step 7: Refrigerant Charging

-

R-32 comes pre-charged for a set line length (usually 15 ft).

-

If longer, the tech must weigh in extra refrigerant precisely by digital scale (not “by pressure”).

-

Open valves slowly to allow refrigerant into system.

🧪 Step 8: System Start-Up & Testing

-

Turn power ON, set thermostat to cool.

-

Measure pressures, subcooling, superheat, and amp draw.

-

Compare to manufacturer charts.

-

Listen for vibration or hissing; none should be present.

Jake’s Homeowner Checklist:

✔ Pad level & stable

✔ Nitrogen test completed

✔ Vacuum pulled below 500 microns

✔ Correct electrical breaker & disconnect installed

✔ R-32 labeling in place

✔ Start-up readings recorded

If your installer skips any of those, ask questions — politely but firmly.

⚡ 7. Electrical Wiring & Controls

The electrical setup may not be glamorous, but it’s critical.

Key Requirements

-

Dedicated circuit: Don’t share with appliances.

-

Breaker size: Match nameplate amperage (e.g., 25–40 A).

-

Wire gauge: Usually 10-12 AWG copper, but confirm per distance.

-

Disconnect box: Within 6 ft of the condenser, visible, and lockable.

-

Grounding: To an earth-bonded conductor — required by NEC 250.

For systems with variable-speed or communicating controls, use shielded low-voltage cable to avoid signal interference.

📘 Reference: NFPA – NEC HVAC Wiring Standards

Jake’s Tip: “Ask your installer to tighten all lugs twice — once cold, once after energizing. Heat can loosen fresh copper joints.”

🧯 8. Refrigerant Handling: Pressure, Charging & Leak Checks

This is where pros earn their pay. R-32’s efficiency relies on precise charge and leak-free piping.

Step 1: Pressure Testing

Using nitrogen ensures moisture and oxygen never enter the system. A stable reading (e.g., 300 psi) over 15+ minutes confirms integrity.

Step 2: Deep Vacuum

Pulling a deep vacuum removes air and moisture that would otherwise form acids and reduce compressor life. Target: 500 microns or better.

Step 3: Weigh-In Charging

R-32 charge amounts are exact — often less than 1 kg difference between under/overcharge can alter performance. Always use a digital scale.

Step 4: Leak Verification

After charging, run the system and check all joints for leaks using an A2L-compatible electronic detector.

📗 More Info: Daikin – R-32 Charging and Leak Management

Jake’s Reminder: “A proper install should never need topping up for years. If your system loses charge early, that’s a workmanship issue — not refrigerant magic.”

🧾 9. Final Testing & Commissioning

Before anyone calls the job done, these commissioning checks must be completed:

| Test | Target / Status |

|---|---|

| Vacuum Hold | ≤ 500 microns for ≥ 10 min |

| Line Pressures | Match manufacturer chart (ambient corrected) |

| Subcool / Superheat | Within ± 2°F of spec |

| Voltage at Compressor | 208–240 V, stable |

| Amperage | ≤ nameplate max |

| Airflow | ~400 CFM/ton |

| Condensate | Drains freely |

| Noise / Vibration | Minimal |

| Labels & Docs | Installed & signed off |

Once those pass, your installer should complete a startup form and provide:

-

System model/serial numbers

-

Charge weight verified

-

Pressure readings

-

Warranty registration

Keep that document — it proves the system was installed per spec.

📘 Reference: EnergyStar – HVAC Quality Installation Checklist

🧼 10. After Installation: Maintenance for Long-Term Performance

Even the best install needs regular care. Here’s what I do seasonally:

Spring Startup

-

Clear leaves/debris around the condenser.

-

Rinse coils with low-pressure water (no harsh sprays).

-

Inspect electrical panel for corrosion.

-

Check that the condenser pad hasn’t settled unevenly.

Summer

-

Verify airflow — no obstructions near fan discharge.

-

Monitor sound — buzzing or rattling means loose bolts.

-

Ensure refrigerant line insulation is intact.

Fall

-

Clean coils again before winter storage (if cooling-only).

-

Cover only the top (never wrap entire unit airtight).

-

Check disconnect box for moisture or insect nests.

Yearly Pro Service

-

Coil deep cleaning

-

Electrical tightening

-

Amperage and pressure checks

-

Refrigerant leak test

Jake’s Note: “Preventive maintenance is the difference between a 10-year unit and a 15-year one.”

📗 Learn More: EnergyStar – Maintaining Your Air Conditioner

🧠 11. Jake’s Recap: 10 Essentials Before You Set Up an R-32 Condenser

-

Plan your site: Airflow, drainage, clearance.

-

Check electrical: Dedicated circuit, breaker, and disconnect.

-

Verify certification: Only EPA 608 or equivalent techs should handle R-32.

-

Insist on pressure & vacuum tests.

-

Confirm proper refrigerant charge (weighed in).

-

Inspect labeling — “R-32 (A2L)” should be visible.

-

Record startup pressures and subcool readings.

-

Keep your warranty paperwork.

-

Schedule first maintenance after 1 year.

-

Stay informed — you own the system, not just the bill.

Jake’s Quote:

“Preparation doesn’t mean doing it yourself. It means knowing what done right looks like — so you can recognize quality when you see it.”

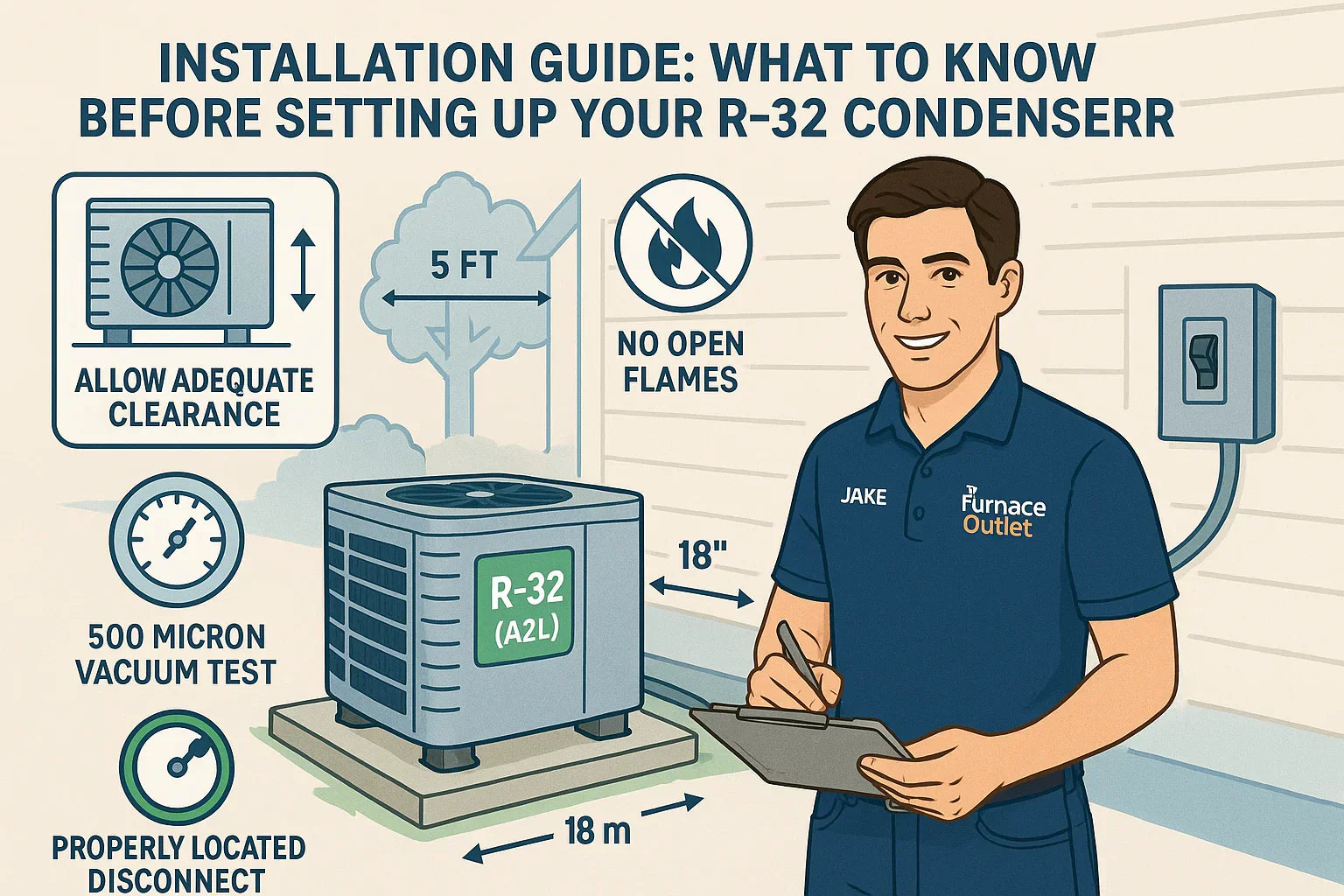

🖼️ 13. Visual Concept for This Article

Scene: Jake stands beside a newly installed R-32 condenser on a level pad, checking his installation checklist.

Key callouts:

-

18 in side clearance

-

5 ft overhead clearance

-

Electrical disconnect within reach

-

“R-32 (A2L)” safety label visible

-

“500 micron vacuum test passed” badge in corner

Color palette: cool metallic blue + eco-green for efficiency emphasis.

Icons for each major step — tools, wiring, refrigerant, testing, maintenance — keep readers oriented.

🧩 14. Final Words

Setting up an R-32 condenser is more than just connecting lines and turning on the power. It’s about precision — the right charge, the right clearances, and the right safety practices. Whether you’re a homeowner like me verifying an installer’s work or a first-time buyer wanting to understand the process, taking the time to get this right ensures:

-

Peak efficiency from day one

-

Longer system lifespan

-

Safer, greener operation

-

Lower utility bills month after month

If your installer walks you through these same steps — pressure test, vacuum, proper charge, and commissioning — you’ll know your R-32 system was installed correctly.

And if you’re ever in doubt? Pull out this guide, check the boxes, and remember: an informed homeowner is the best warranty a system can have.

In the next topic we will know more about: Cost Breakdown: How Much Does an R-32 Condenser Installation Really Cost in 2025?