🌟 Introduction

If you’ve ever stayed in a hotel room, you’ve likely experienced a PTAC (Packaged Terminal Air Conditioner). These units deliver heating and cooling in one self-contained package, usually installed through a wall sleeve. In recent years, PTACs have become popular for apartments, condos, home offices, and guest spaces, because they’re space-saving, efficient, and relatively easy to install.

But if you’re installing a PTAC with a 5 kW electric heat kit, there are some extra things to know. That heating element draws serious power, which means you need to be especially mindful about electrical setup, wall preparation, and safety codes.

Amana Distinctions Model 9,200 BTU PTAC Unit with 5 kW Electric Heat

In this guide, I’ll break down everything you need to know — from pre-installation planning to step-by-step installation and common mistakes to avoid — so you’ll know whether you can DIY this project or when it’s smarter to call a pro.

📌 Section 1: Understanding PTAC Installation Basics

🔍 What is a PTAC?

A Packaged Terminal Air Conditioner is a self-contained HVAC system that provides both cooling and heating, installed directly through an exterior wall using a standardized wall sleeve (Energy.gov).

🔥 Why the 5 kW Electric Heat Kit Matters

-

5,000 watts = ~17,000 BTUs of heat output

-

Requires 208/230V electrical service

-

Needs a dedicated breaker (20–30A depending on unit)

-

Increases installation complexity compared to a cooling-only PTAC

👉 Translation: installing a 5 kW heat-equipped PTAC isn’t as simple as sliding in a window unit — it’s a small-scale HVAC job that needs proper planning.

📝 Section 2: Pre-Installation Checklist

Before unboxing your new Amana, GE, or Friedrich PTAC, make sure you’ve checked these off:

-

Wall Opening Size

-

Standard PTAC wall sleeves are 42 inches wide × ~16 inches high.

-

Depth varies (usually ~14"). Verify your unit’s spec sheet (The Furnace Outlet).

-

-

Wall Support & Framing

-

Cut and frame the wall opening to fit the sleeve.

-

Use pressure-treated lumber for framing exposed to moisture.

-

-

Electrical Capacity

-

PTAC with 5 kW heater draws 20–30 amps.

-

Ensure you have a dedicated 208/230V circuit with correct wire gauge.

-

Verify breaker size against the manufacturer’s installation manual.

-

-

Drainage Considerations

-

PTACs produce condensate water during cooling.

-

Sleeve must slope slightly (about 1/4" downward to the outside) to ensure proper drainage.

-

-

Safety Prep

-

Turn off power at the panel before wiring.

-

Wear safety glasses, gloves, and use proper tools.

-

👉 Skipping any of these steps could lead to electrical hazards, water leaks, or poor performance.

🧰 Section 3: Tools & Materials You’ll Need

-

PTAC unit (with 5 kW electric heat)

-

Wall sleeve (correct size for unit)

-

Exterior grille (to prevent rain/debris entry)

-

Dedicated electrical disconnect and proper wiring

-

Sealant/insulation foam for gaps

-

Level & tape measure

-

Drill, screws, anchors

-

Caulk gun & silicone sealant

-

Protective gear (gloves, safety glasses)

Optional but useful: stud finder, reciprocating saw (if cutting new opening).

🛠️ Section 4: Step-by-Step Installation Process

Here’s the Savvy step-by-step you can follow:

1. Prepare the Wall Opening 🧱

-

Measure twice, cut once.

-

Frame out the opening to the PTAC sleeve dimensions.

-

Ensure framing is square and level.

2. Install the Wall Sleeve 🗂️

-

Slide the wall sleeve into the opening.

-

Slope sleeve slightly downward toward outside for condensate drainage.

-

Anchor sleeve securely with screws into wall framing.

-

Seal perimeter with foam insulation to prevent drafts.

3. Electrical Setup ⚡

-

Run dedicated 208/230V wiring from breaker panel to the PTAC opening.

-

Install disconnect box near the unit for service access (NFPA 70 NEC code).

-

Wire according to the PTAC manufacturer’s electrical diagram.

-

Always double-check breaker size against heater wattage.

4. Insert the PTAC Unit 🧊🔥

-

Slide the PTAC chassis into the wall sleeve.

-

Secure with mounting brackets (often included).

-

Check level and adjust as needed.

5. Attach Exterior Grille 🌬️

-

Install grille on the outdoor side of sleeve.

-

Prevents rain entry, pests, and debris buildup.

6. Seal & Finish 🧴

-

Caulk around sleeve edges inside and outside.

-

Add trim kit (if included) for a clean look.

7. Final Connections & Power-On Test 🔌

-

Connect unit to electrical disconnect.

-

Turn on breaker.

-

Test cooling, heating, fan, and thermostat functions.

-

Check airflow and confirm drainage outside.

⚠️ Section 5: Common Mistakes to Avoid

-

Wrong Sleeve Size → Won’t fit, causes drafts.

-

No Drainage Slope → Water leaks into room.

-

Undersized Circuit → Tripped breakers, fire risk.

-

Improper Sealing → Energy waste, pests, drafts.

-

Skipping Grille Install → Weather and insects invade unit.

🛡️ Section 6: Safety & Code Compliance

-

Electrical Code: PTAC units with 5 kW heaters require proper breaker sizing and wiring per NEC code.

-

Fire Safety: High-wattage electric heaters demand safe wiring to prevent overheating.

-

Local Permits: Some municipalities require electrical permits.

-

Professional Oversight: Even if you DIY the sleeve, hire an electrician for wiring.

👉 Don’t cut corners — the 5 kW heater can draw nearly 5,000 watts continuously, so mistakes are costly and dangerous.

👩🔧 Section 7: DIY vs. Professional Installation

DIY Makes Sense If:

-

You’re replacing an existing PTAC in the same sleeve.

-

You’re comfortable with basic carpentry and sealing.

-

Electrical is already in place.

Call a Pro If:

-

You’re cutting a new wall opening.

-

You need a new dedicated circuit.

-

You’re unsure about wiring codes.

Cost Breakdown 💲

-

DIY replacement: ~$100–$150 for materials (sealant, tools).

-

Professional install: $500–$1,200 depending on electrical work.

-

Peace of mind: Priceless if you’re unsure about wiring.

🔎 Section 8: Post-Installation Tips

-

Test in both heating and cooling modes before calling it done.

-

Listen for unusual noises (vibrations mean re-leveling needed).

-

Check for drafts around sleeve — reseal if needed.

-

Inspect condensate drainage outside during cooling.

-

Register warranty with manufacturer to protect your investment.

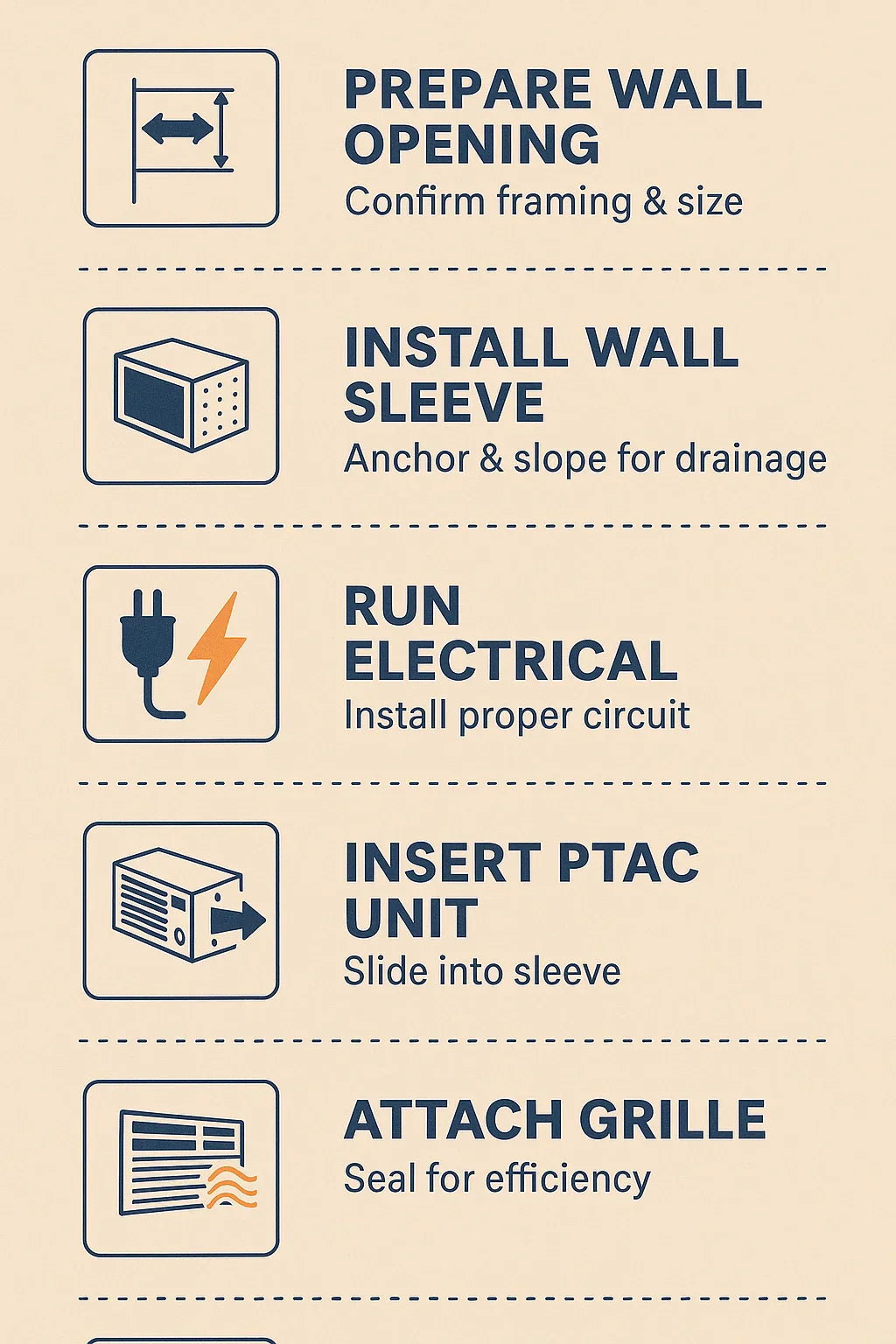

🎨 Infographic Concept

Installation Timeline (6 Steps) with icons:

-

Prep wall opening (📏)

-

Install wall sleeve (🗂️)

-

Run electrical (⚡)

-

Insert PTAC (❄️🔥)

-

Attach grille (🌬️)

-

Power test (🔌)

Colors: Warm beige background, clean modern icons, homeowner-friendly style.

🌟 Conclusion

Installing a PTAC with 5 kW electric heat isn’t a weekend beginner project — but it’s absolutely manageable with proper preparation.

-

Plan your wall opening carefully.

-

Size your circuit correctly.

-

Don’t skip drainage slope or sealing.

-

Know when to call a pro.

With the right steps, you’ll end up with a unit that runs safely, efficiently, and keeps your room comfortable all year long.

Savvy’s advice: Be realistic about your skills. If you can handle the carpentry and sealing, great. But for wiring a 5 kW heater? That’s one place where hiring a licensed electrician is worth every penny.

In the next topic we will know more about: How Efficient Is the Amana 9,200 BTU Unit? EER, CEER & Real-World Energy Costs